Method for making grain on double sides by suction for artificial leather production and double-side grain suction-making equipment

A double-sided texture-absorbing, artificial leather technology, applied in textile and papermaking, fabric surface trimming, thorn patterns, etc., can solve problems such as unfavorable production efficiency, production cost, high labor intensity of operators, and increased labor costs, and simplify multiple Process, reduce labor intensity, reduce labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment describes a double-sided suction method for the production of artificial leather; the method is: a first vacuum roll and a second vacuum roll are provided; the artificial leather is wound on the first vacuum roll and the second vacuum roll in turn; Under the action of traction, the artificial leather moves forward and passes through the first vacuum roller and the second vacuum roller in turn; when the artificial leather passes through the first vacuum roller, one side of the artificial leather is attached to the first vacuum roller, and is sucked through the first vacuum roller. Vacuum treatment makes the first vacuum roller absorb the texture on one side of the artificial leather; when the artificial leather passes through the second vacuum roller, the other side of the artificial leather is attached to the second vacuum roller, and the second vacuum roller is vacuumed inside The second vacuum roll sucks the grain on the other side of the artificial lea...

Embodiment 2

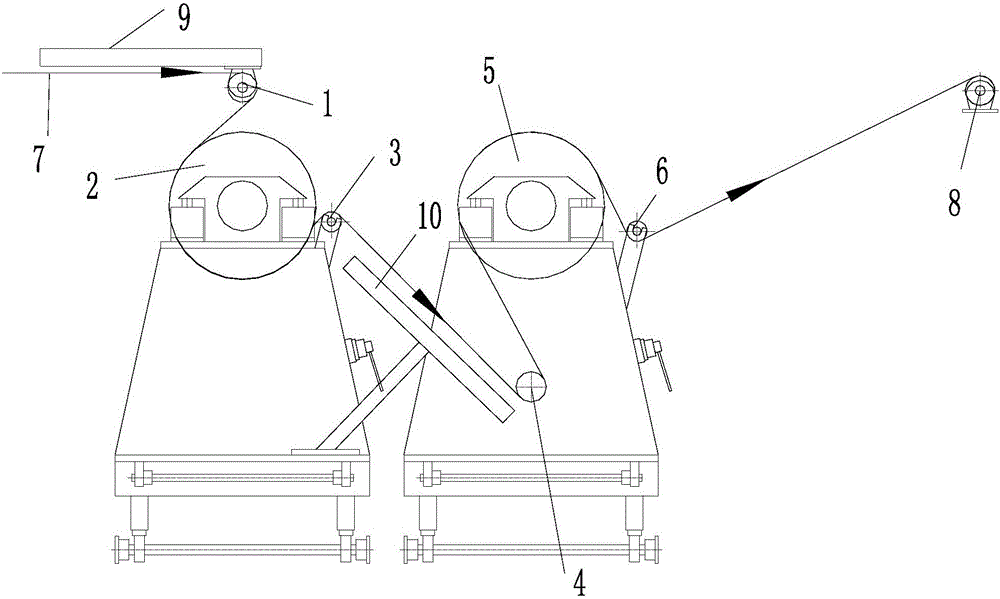

[0031] This embodiment provides a double-sided embossing device for artificial leather production, its structure is as follows figure 1 Shown; including the first feeding guide roller 1, the first vacuum roller 2, the first discharging guide roller 3, the second feeding guiding roller 4, the second vacuum roller 5, the second discharging guiding roller 6 and the blanking Roller 8; also includes a vacuum device respectively connected with the first vacuum roller 2 and the second vacuum roller 5, and a frame. The first feed guide roll 1 is located above the first vacuum roll 2; the first discharge guide roll 3 is located on the side of the first vacuum roll 2 close to the second vacuum roll 5; the second feed guide roll 4 is located on the second vacuum roll Below the roller 5; the second discharge roller is located on the side of the second vacuum roller 5 away from the first vacuum roller 2 . The first feed guide roll 1, the first vacuum roll 2, the first discharge guide roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com