Liquid crystal coating device

A coating device and liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of the impact of product mass production, can not completely eliminate Dropmura defects, etc., to improve product yield, shorten product production time, improve The effect of product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

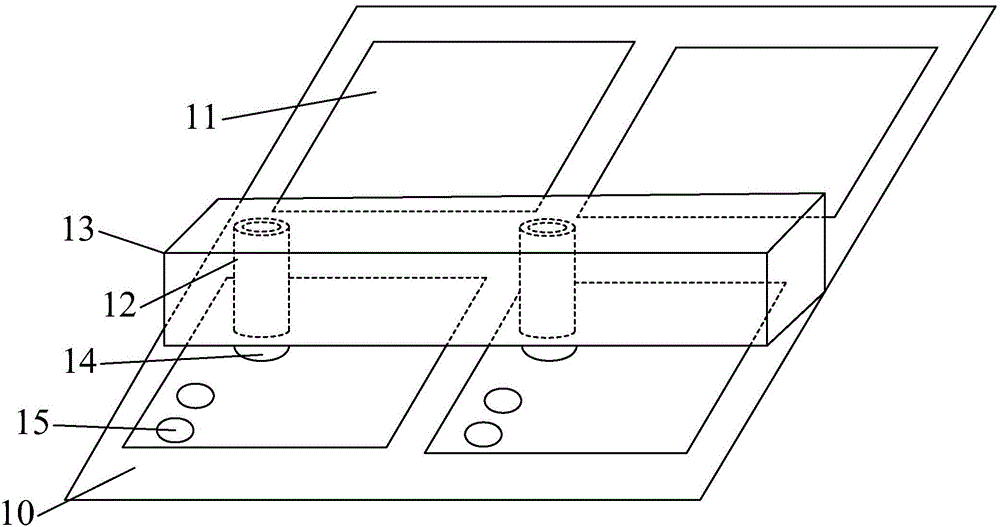

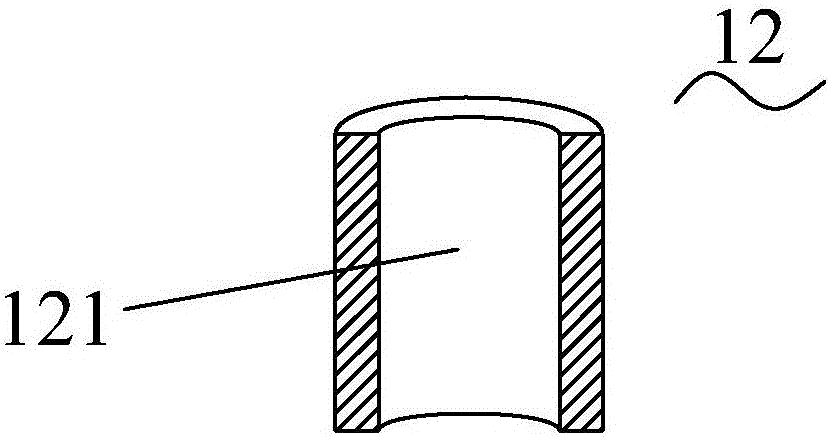

[0029] see Figure 4 to Figure 6 , Figure 4 A schematic diagram of the ODF process for a preferred embodiment of the liquid crystal coating device of the present invention, Figure 5 It is the substrate coated by the ODF process, Image 6 It is a schematic cross-sectional view of a liquid crystal dropper. The preferred embodiment of this liquid crystal coating device comprises a plurality of densely arranged liquid crystal droppers 22, and a shield 23 made of transparent material, and other conventional components such as liquid crystal containers can adopt conventional configurations, which will not be repeated here; The caliber of the guide tube 221 inside the liquid crystal dropper 22 for the liquid crystal to flow becomes larger on the liquid crystal outflow side, and the liquid crystal dropper 22 has a heating device 222 for heating the liquid crystal flowing through to control the temperature of the liquid crystal flowing out. Figure 4 It shows the situation that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com