Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire components, tire edges, transportation and packaging, etc., can solve the problems that it is difficult to obtain bead reinforcement effect, difficult to effectively use, etc., so that the riding comfort will not be reduced and prevent The effect of productivity deterioration and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

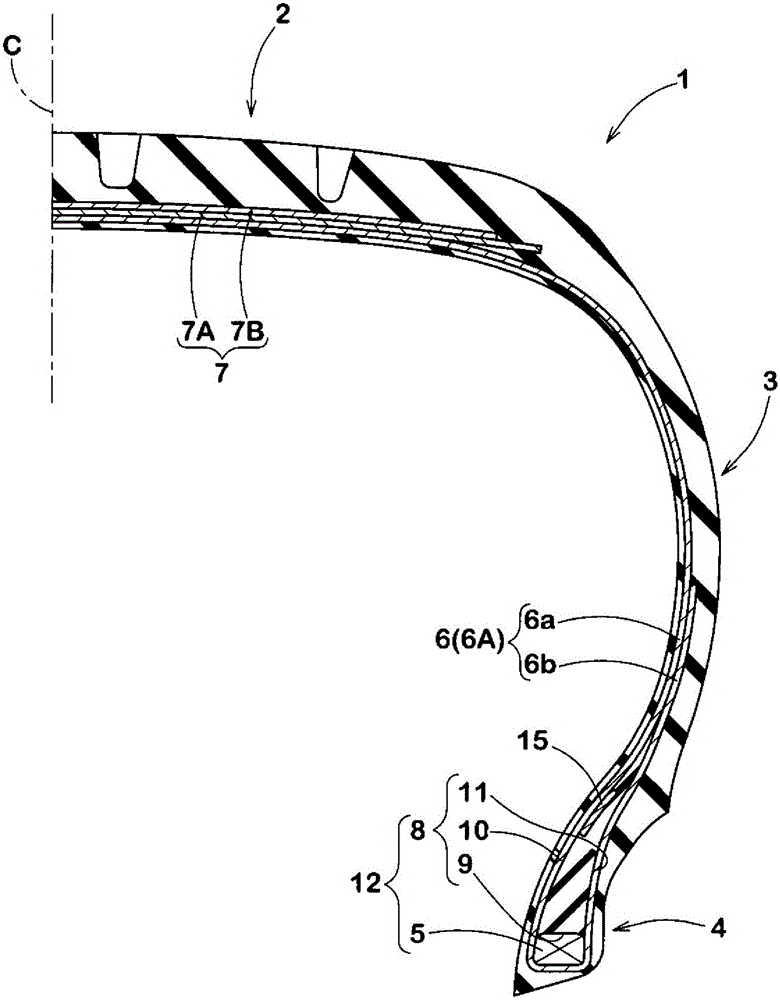

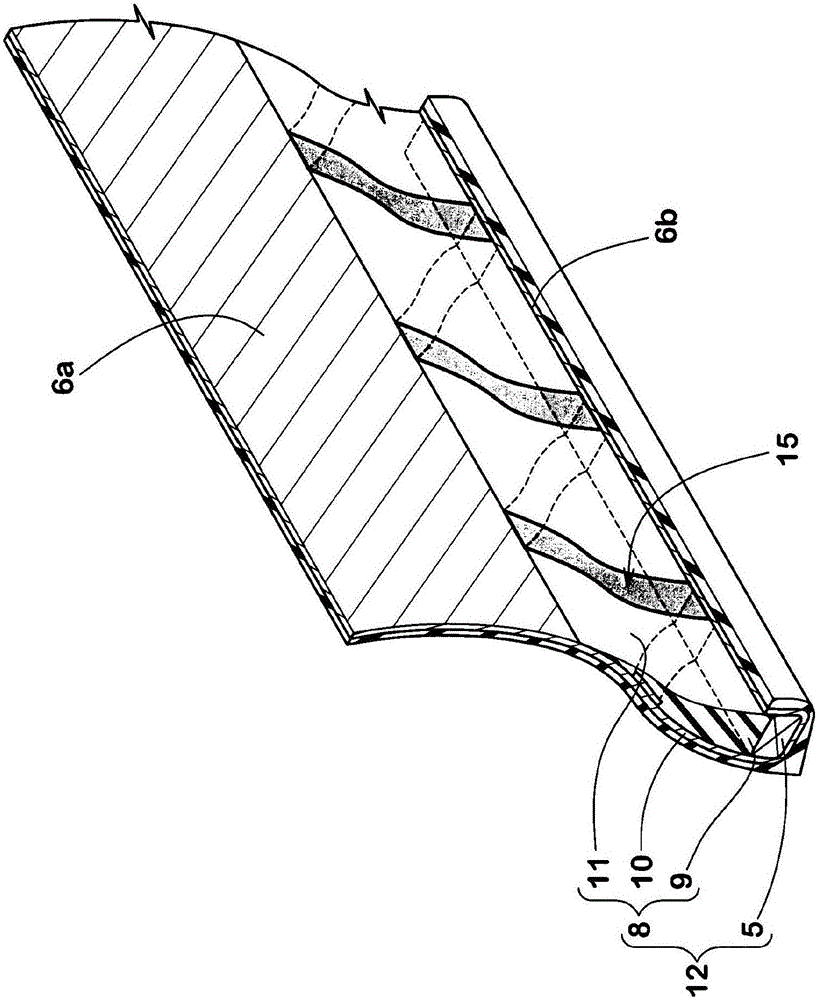

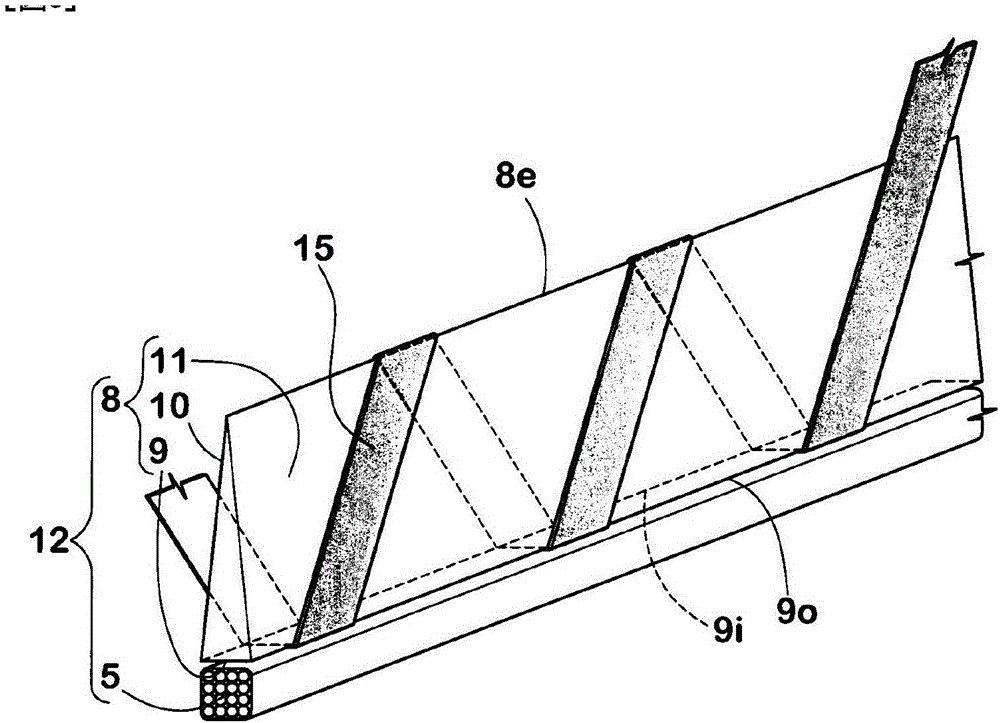

[0055] Prototype has figure 1 The basic structure, and has the image 3 or Figure 4 Pneumatic tires for passenger cars (195 / 65R15) with bead reinforcement materials wound in the form of In addition, as a comparative example, a pneumatic tire without a bead reinforcing layer and a bead reinforcing material (comparative example 1) and a pneumatic tire with Figure 8 Pneumatic tires of the shown bead reinforcement layers (Comparative Examples 2 and 3). In addition, the steering stability and riding comfort of each test tire were tested, and the defective rate during production was measured. The test method is as follows.

[0056]

[0057] The trial tires were mounted on a test vehicle under the following conditions, and the steering stability and ride comfort when driving on a dry asphalt tire test course were evaluated by the driver's senses. As a result, the steering stability and the riding comfort of Example 1 were expressed on a scale of 100 with 75 points each, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com