A stalk-pressing disc cutting and ditching sowing unit

A technology of ditch sowing and disc opener, which is applied in the direction of digging/covering ditch holes, planting methods, agricultural machinery and tools, etc., and can solve the problems of long straws being pressed into the soil and affecting sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

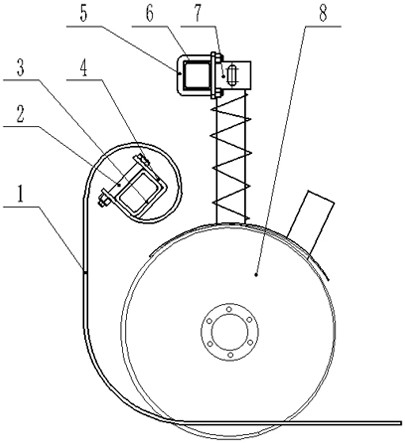

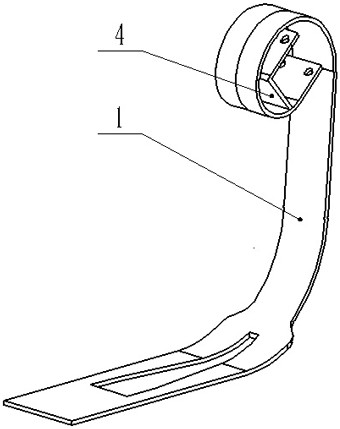

[0013] Specific implementation methods: such as Figure 1~2 The stalk-pressing disk cutting and ditching sowing unit shown is installed on the frame of the planter, mainly including: stalk-pressing device 1, frame beam I3, stalk-pressing installation frame 4, frame beam II6, disc opening Groove assembly 8, assembly mounting frame 7, connecting bolt 2, U-shaped connecting bolt 5. The stalk pressing device 1 is characterized in that it is an elastic arc-shaped plate with a trapezoidal hole groove on the bottom surface, and the upper bending end is a plane, which is welded with the stalk pressing installation frame 4 and installed on the frame with connecting bolts On the beam I3; the disc ditching assembly 8 is characterized in that the bottom of the disc ditching device of the disc ditching assembly 8 is embedded in the trapezoidal hole groove of the stalk pressing device 1, and the bottom of the disc ditching device There is a gap between the side of the trapezoidal hole groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com