Modular Rope-Driven Decoupled Robotic Arm Joint and Its Working Method

A rope-driven, modular technology, applied in the field of robotics, can solve problems such as kinematic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred implementations involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

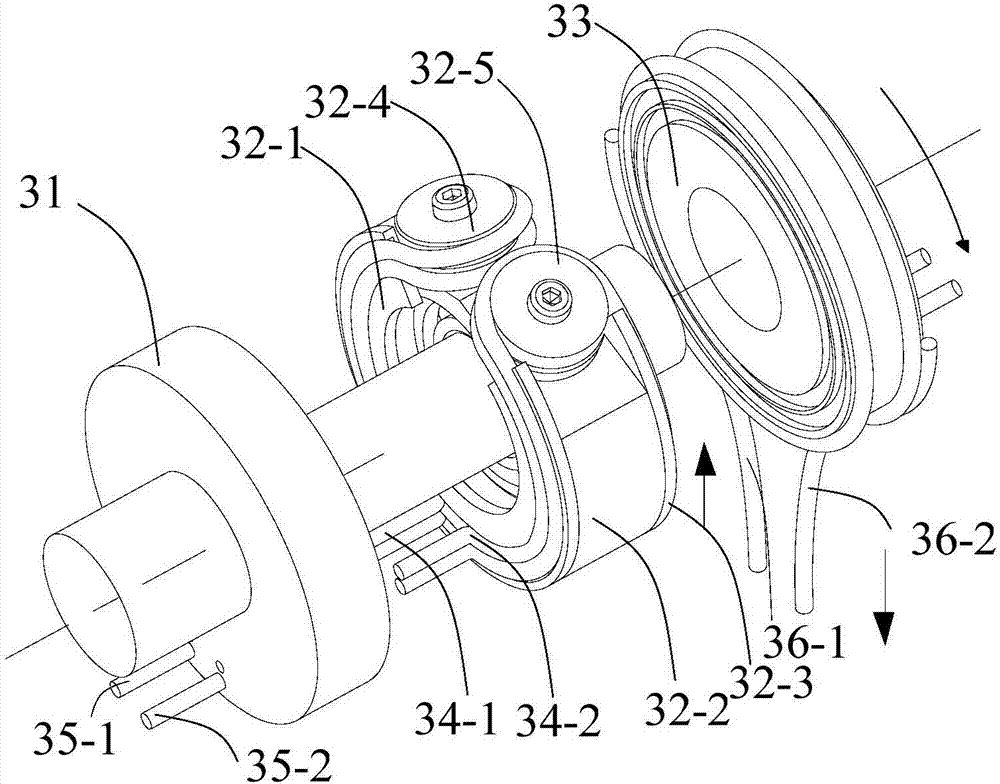

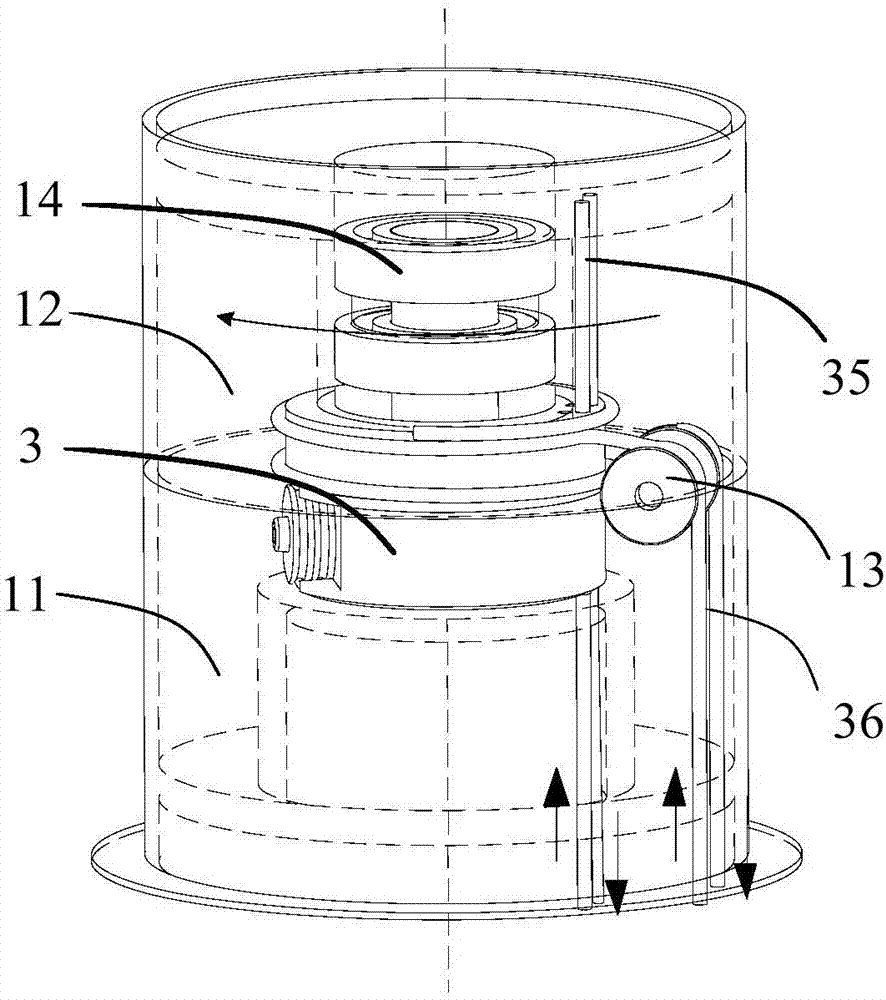

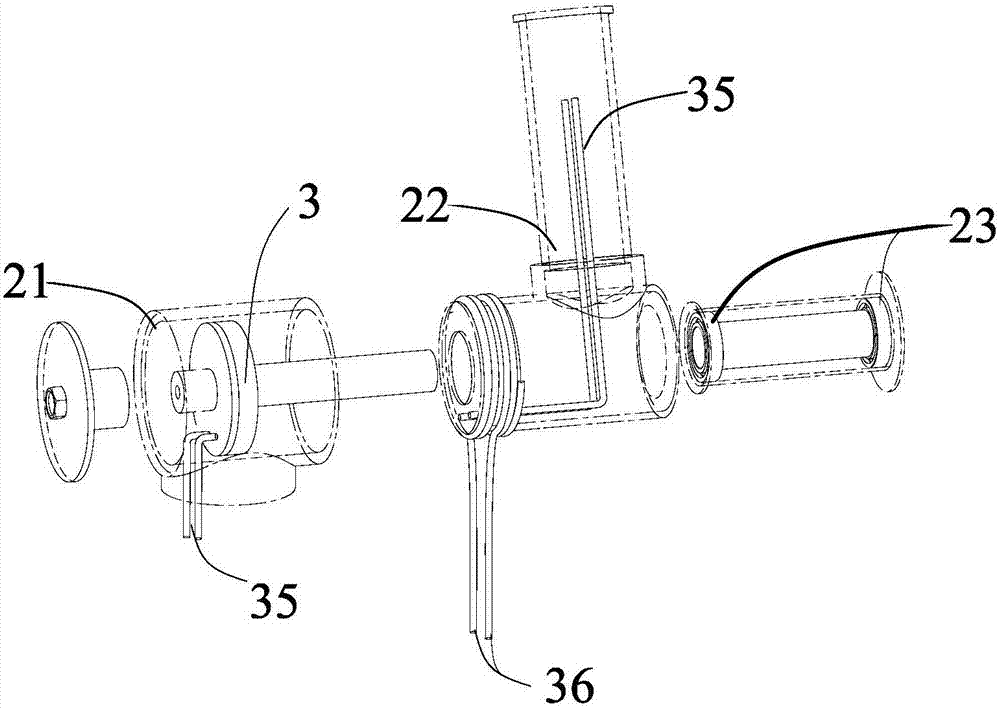

[0058] see figure 1 , 4 As shown in , 5, a mechanism for passive decoupling of the driving rope movement of the rope-driven serial manipulator is provided. The rope motion decoupling mechanism 3 includes a fixed wheel 31, a follower wheel 32, and a driving wheel 33 from front to back; wherein the fixed wheel 31 includes a fixed wheel disc and a fixed wheel axle, and the fixed wheel disc and the fixed wheel axle are fixedly connected to each other. It is fixed and cannot rotate; the follower wheel 32 is installed on the fixed wheel axle, it is driven by the decoupling rope, and the axial displacement is limited; the rope motion decoupling mechanism 3 also includes a left decoupling rope 34-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com