Patents

Literature

33results about How to "High self-weight ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

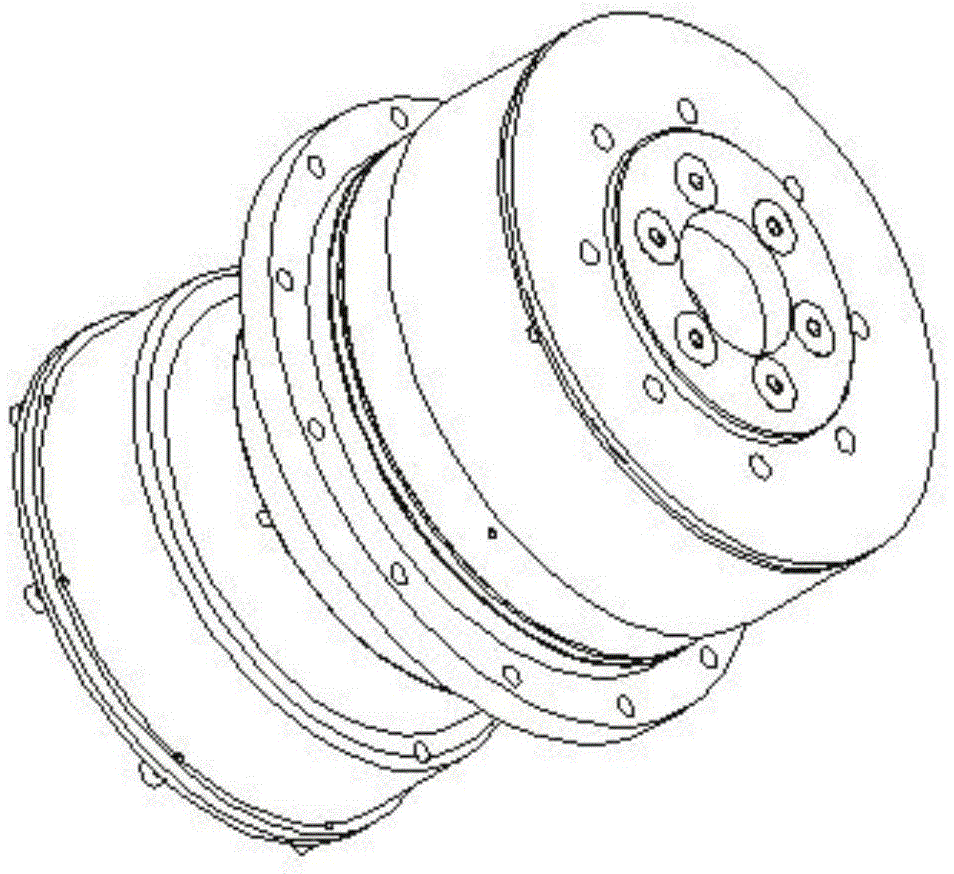

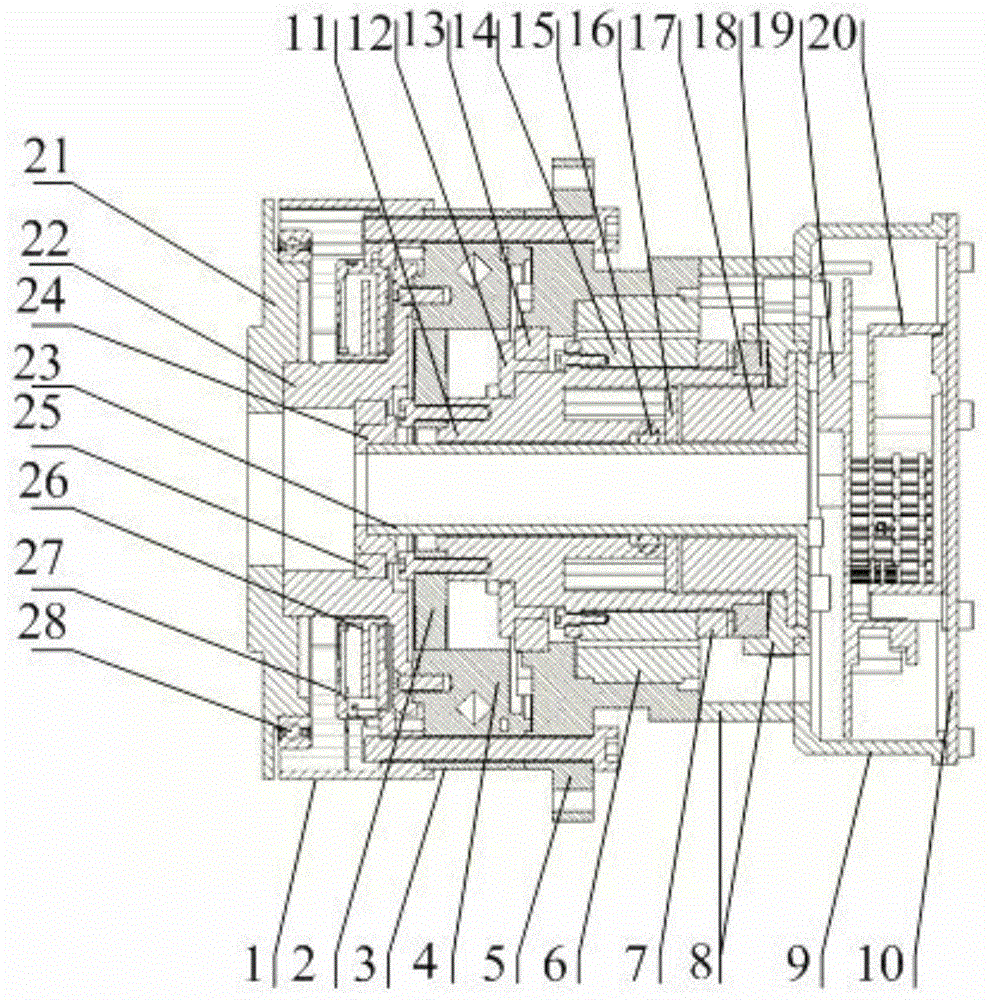

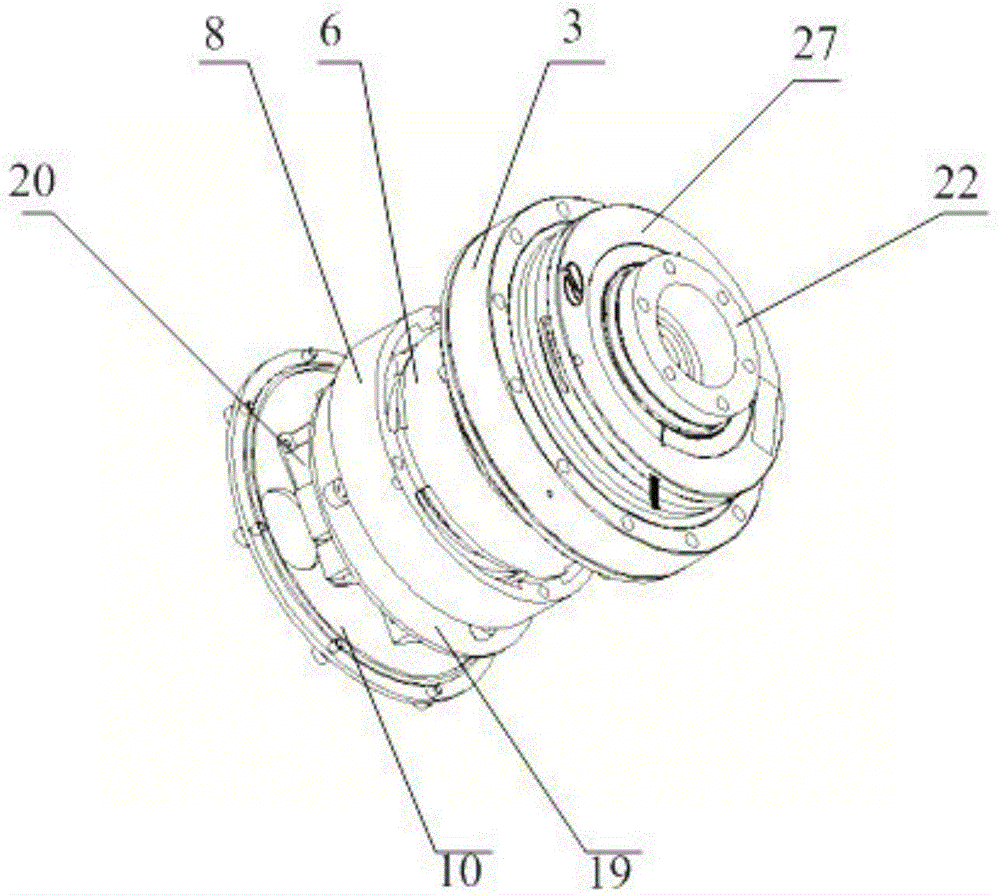

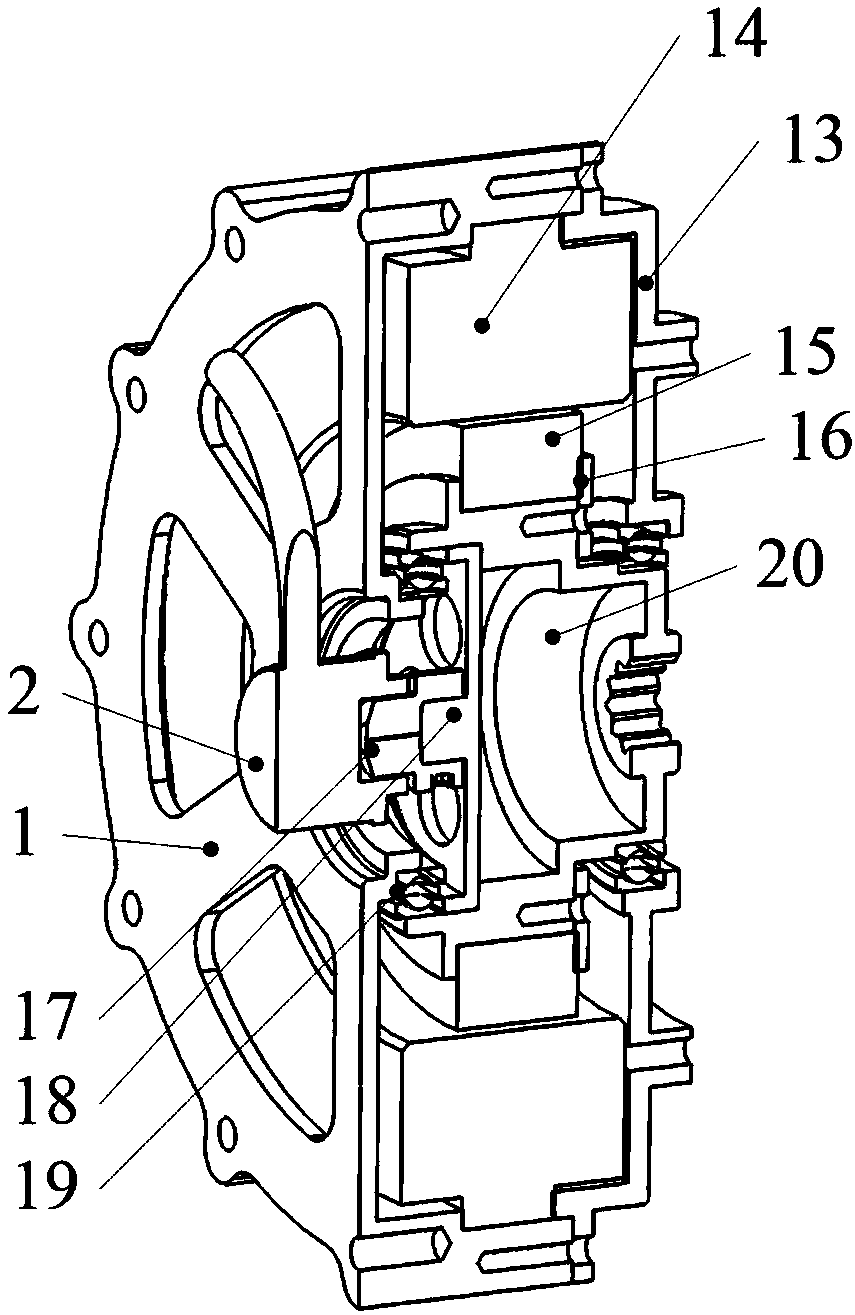

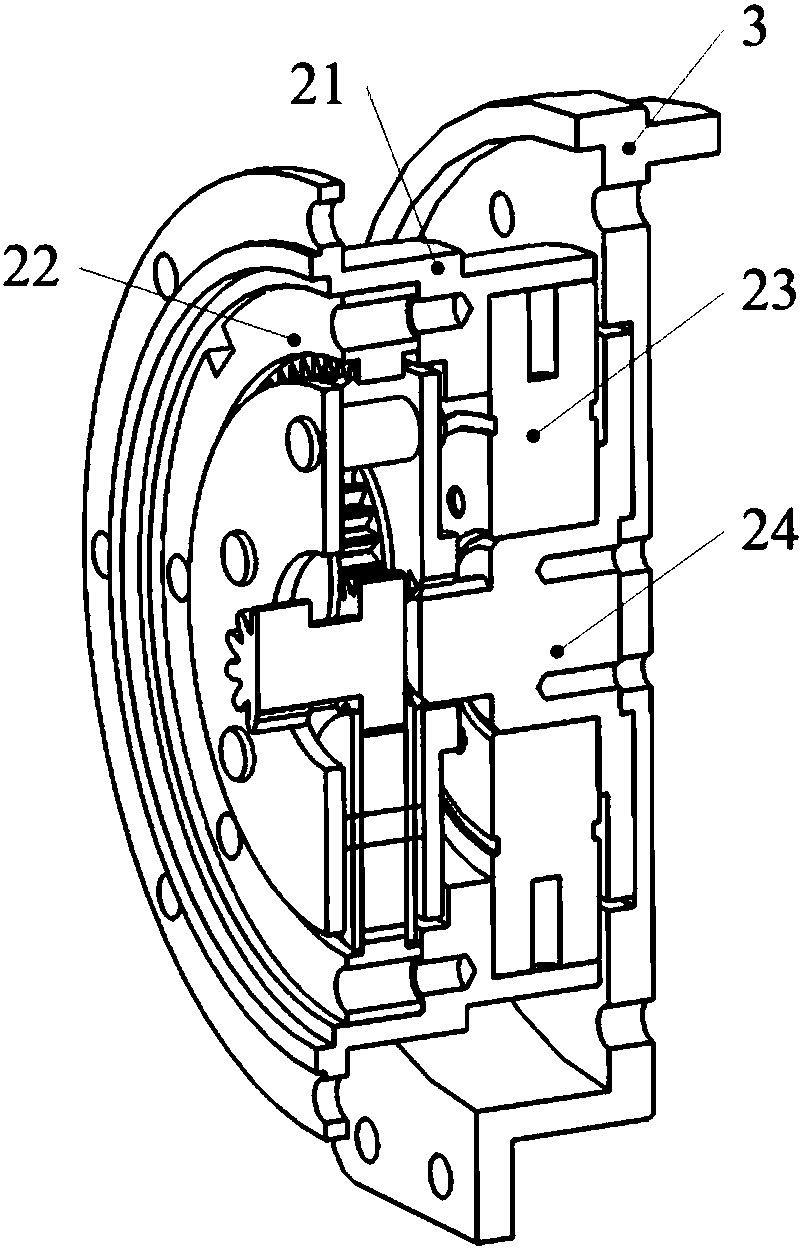

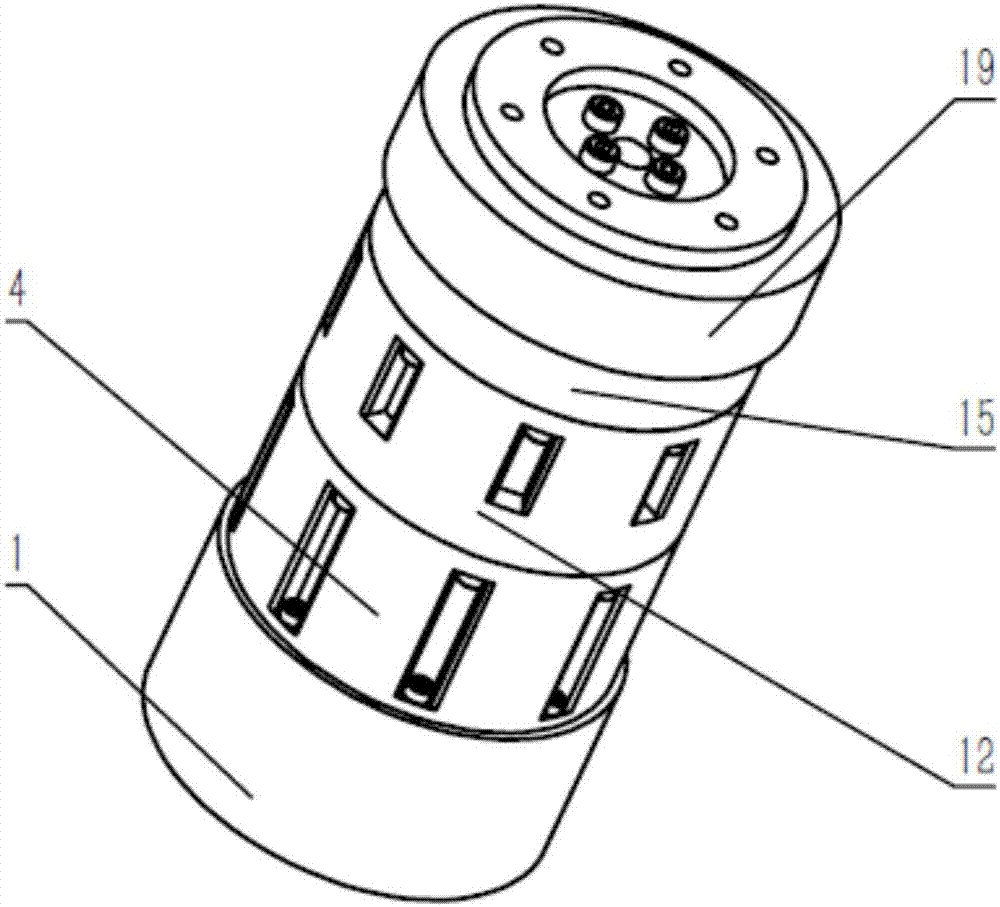

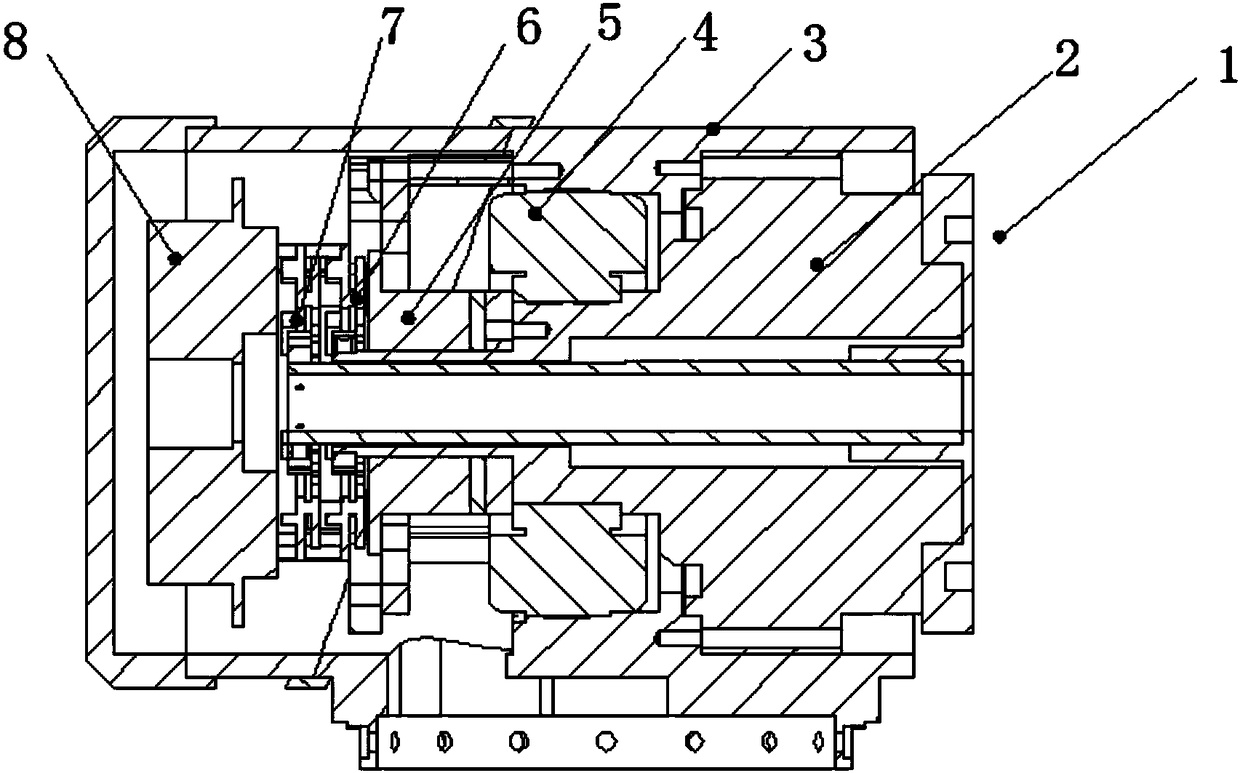

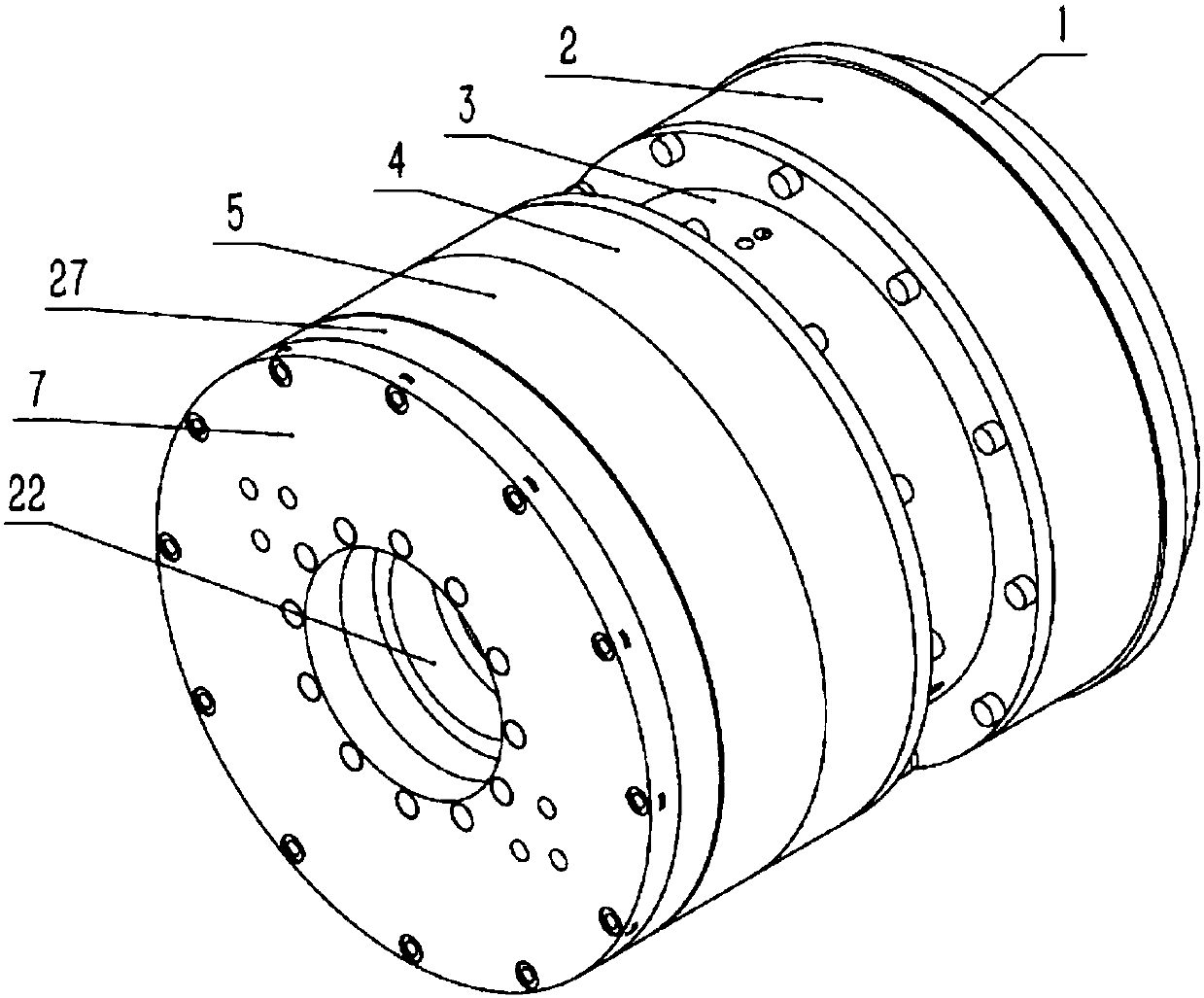

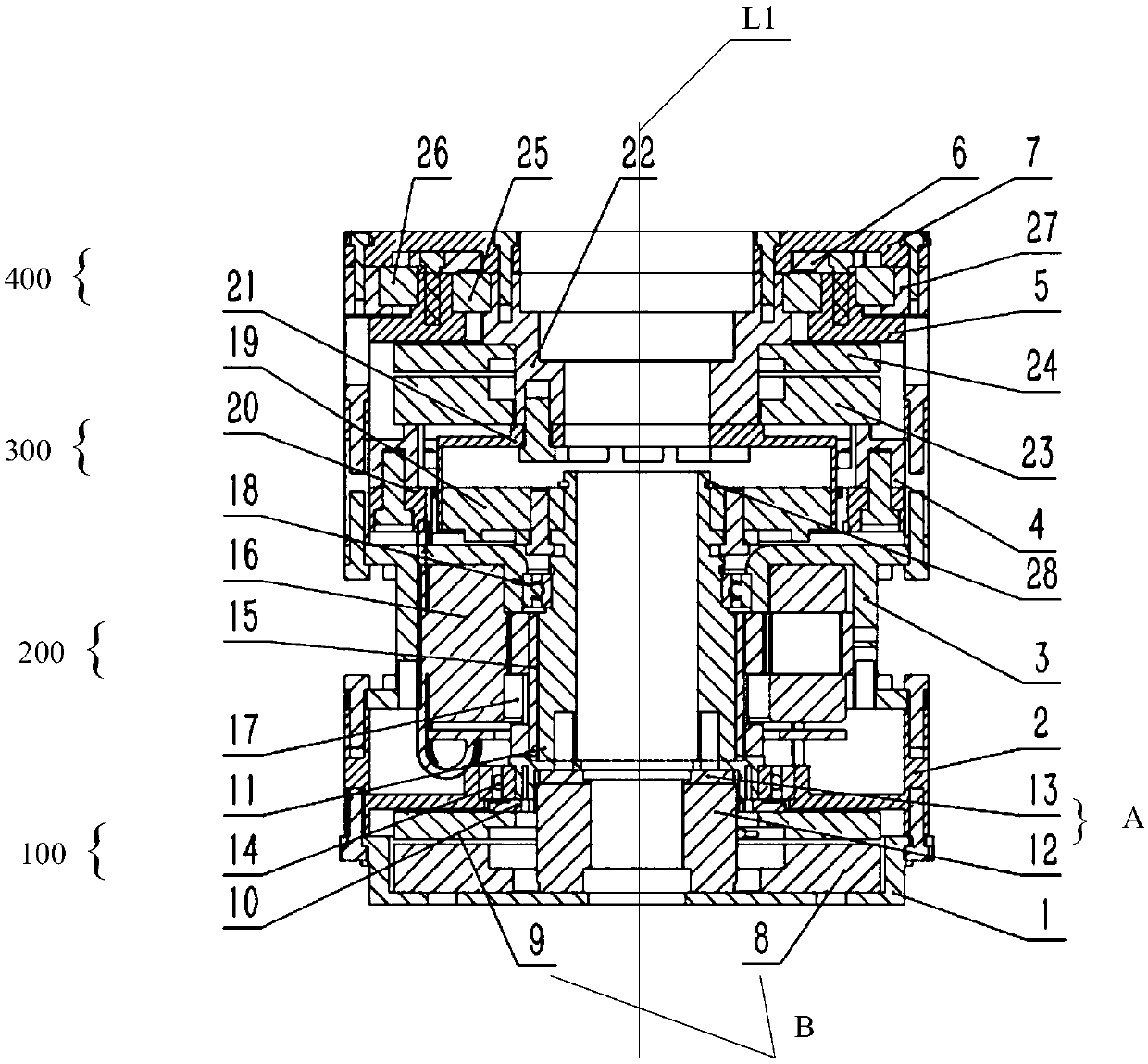

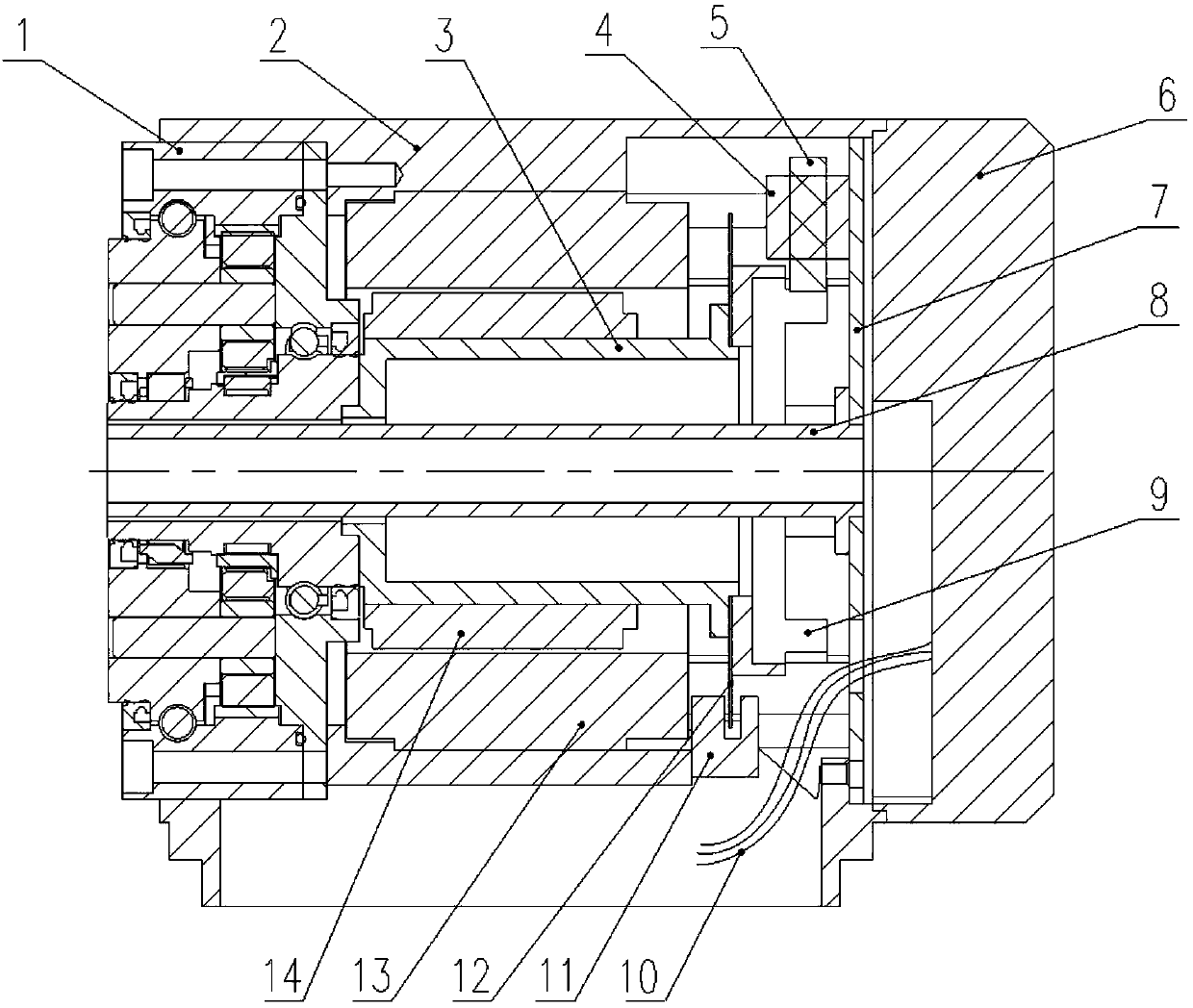

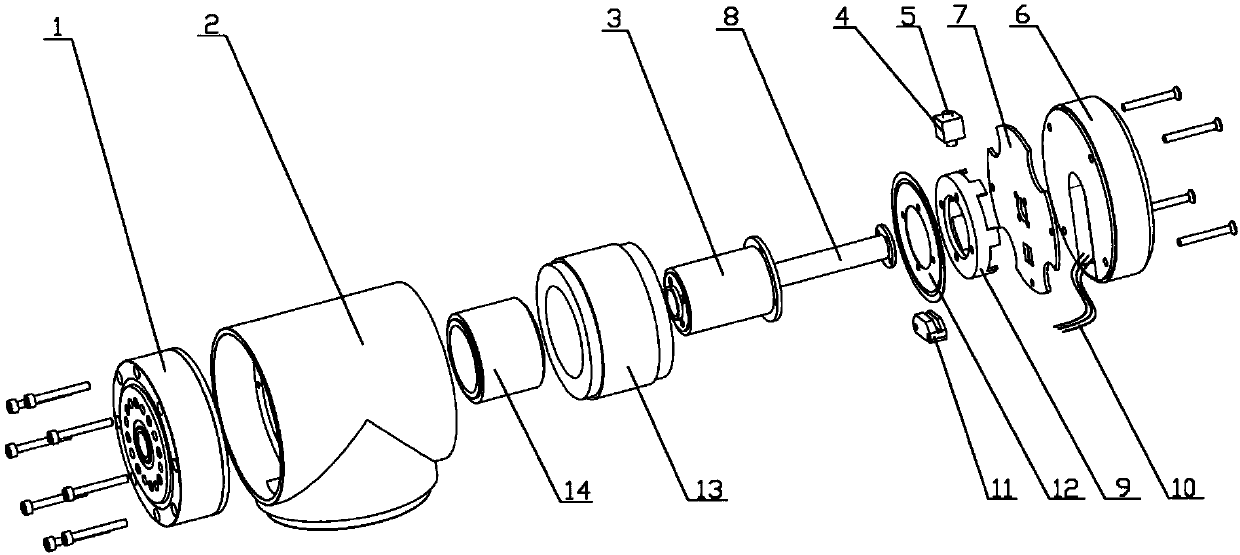

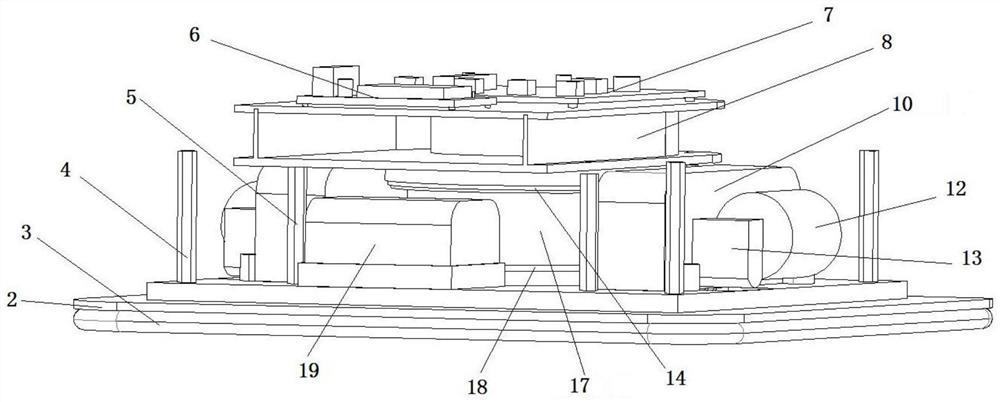

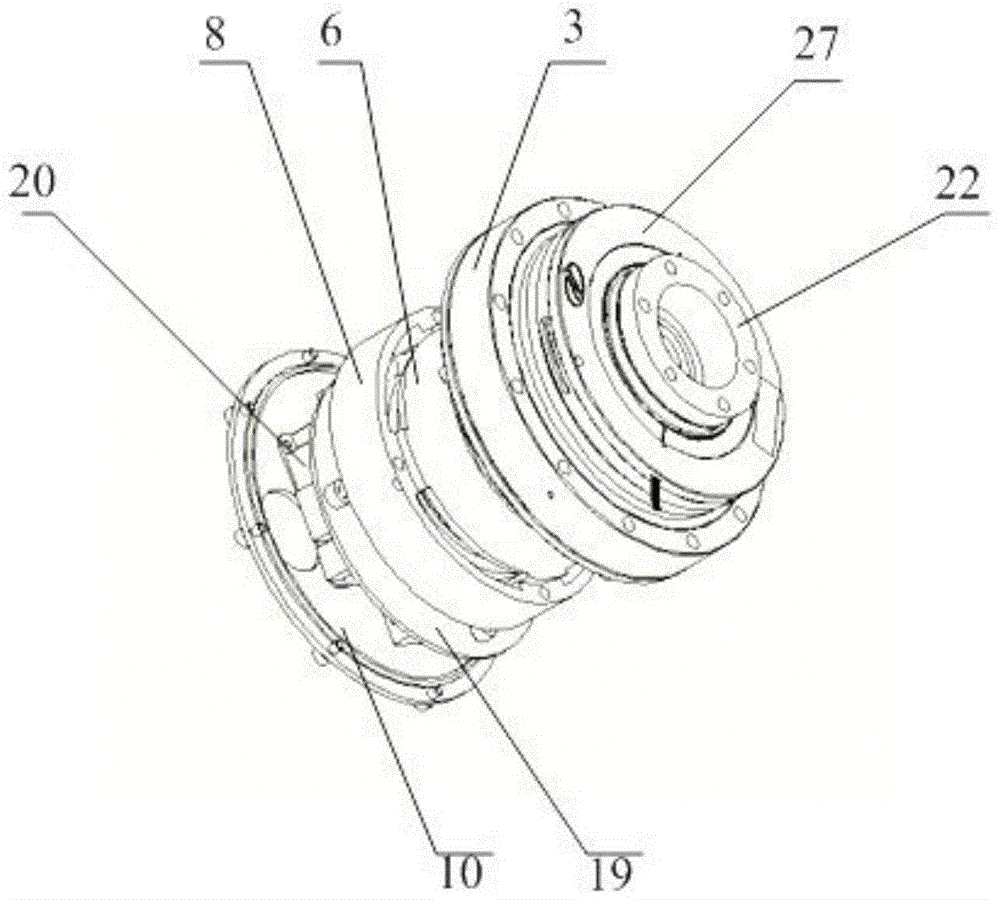

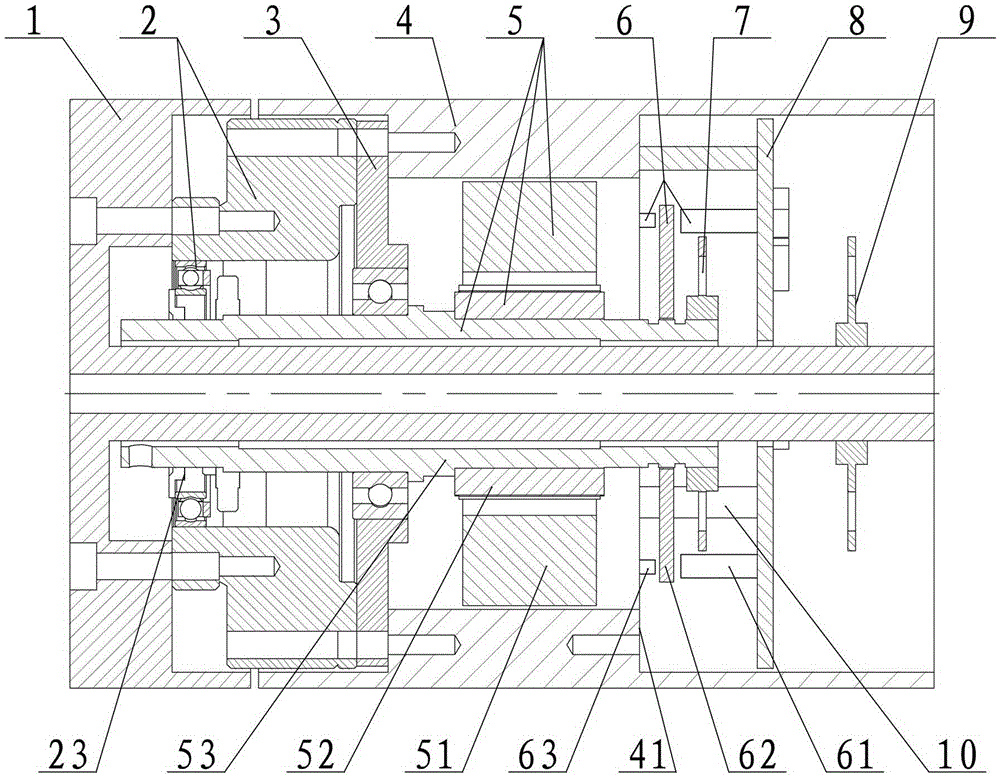

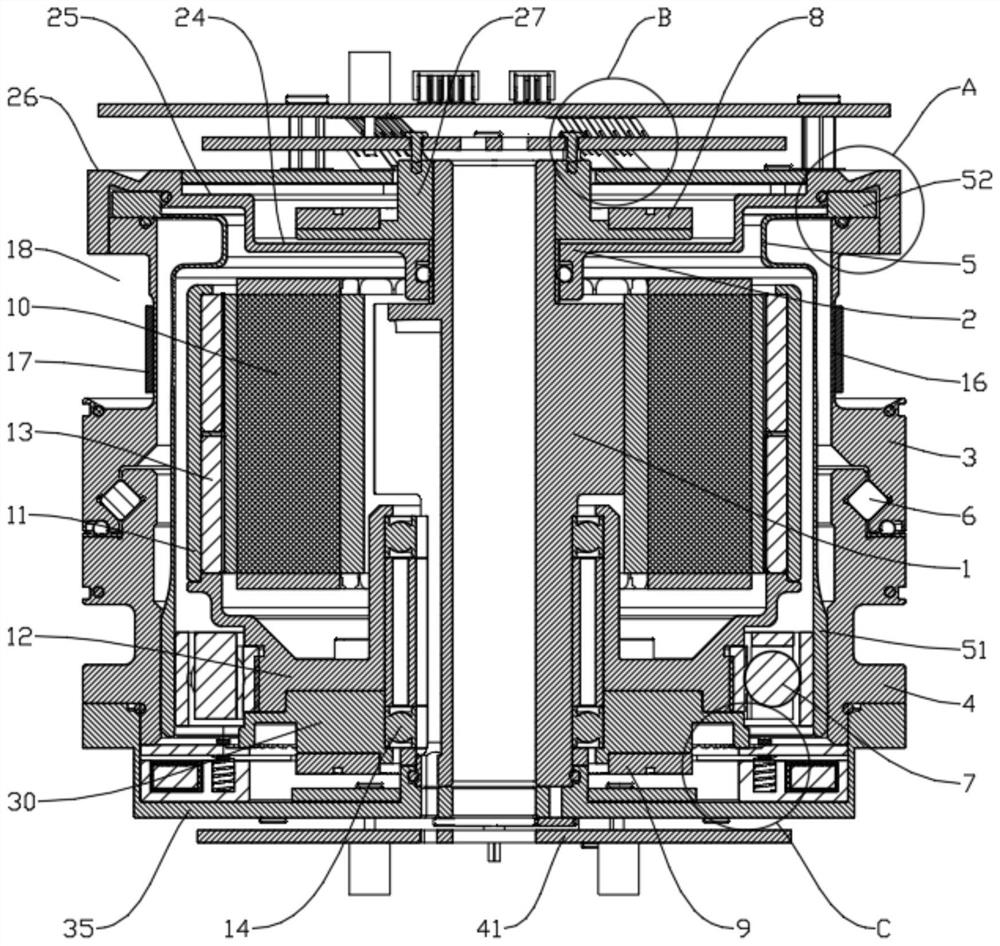

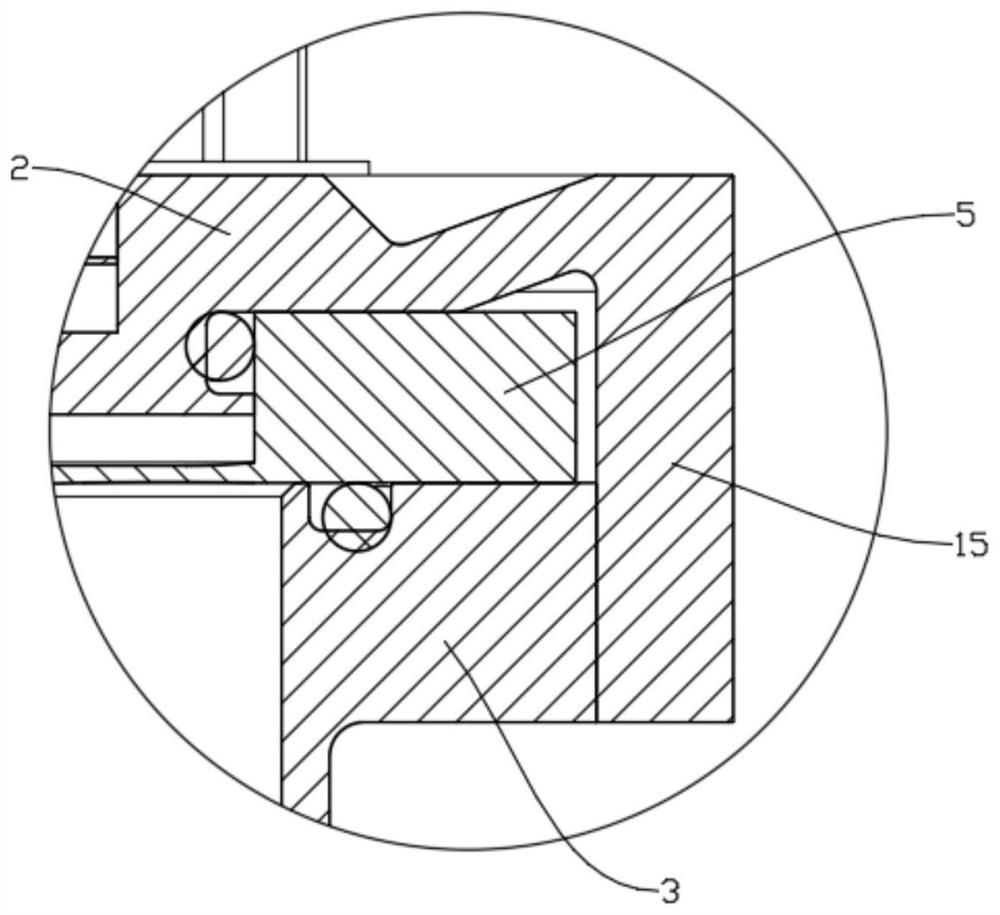

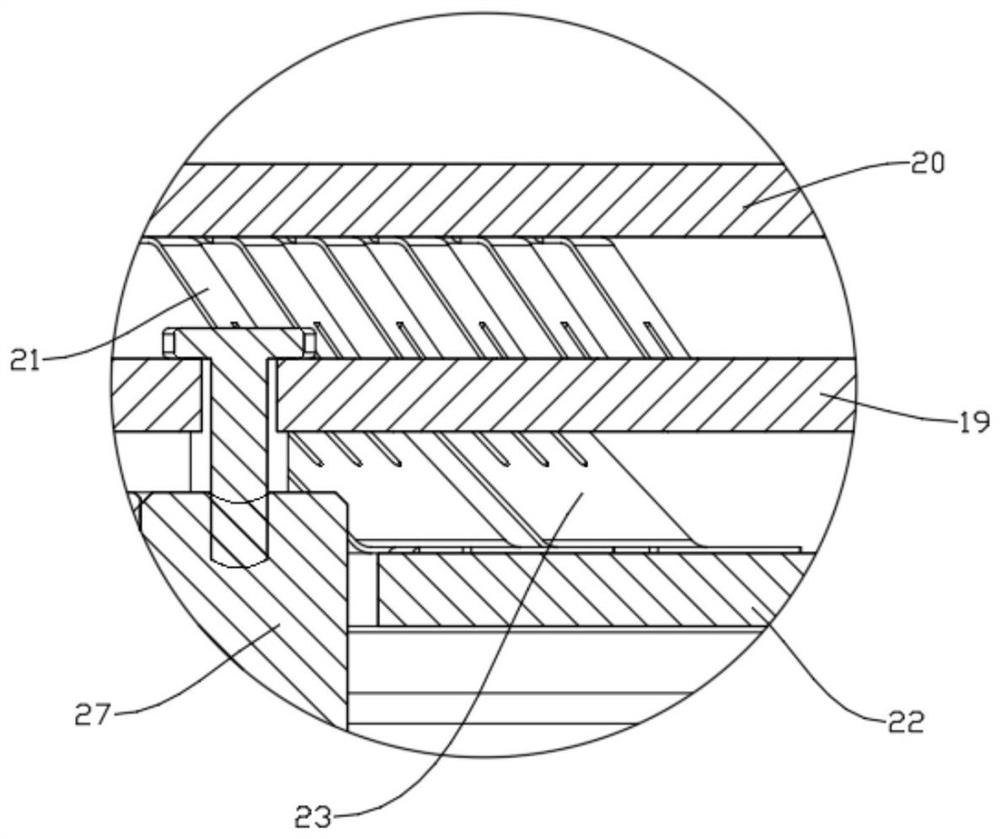

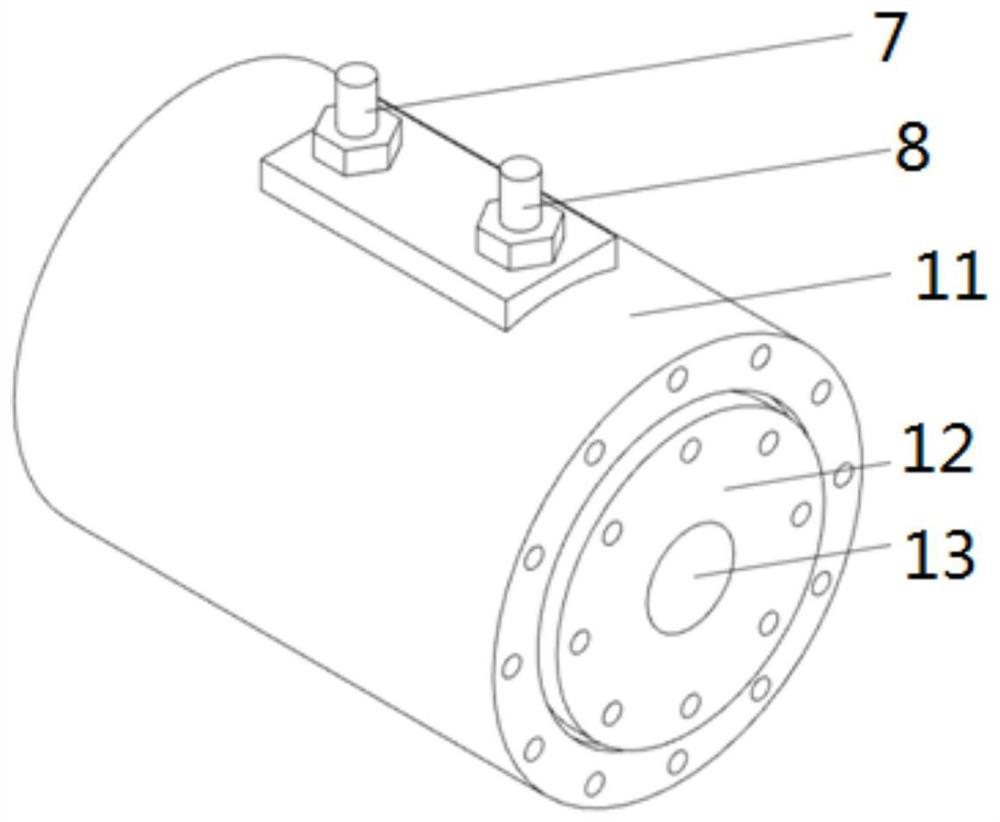

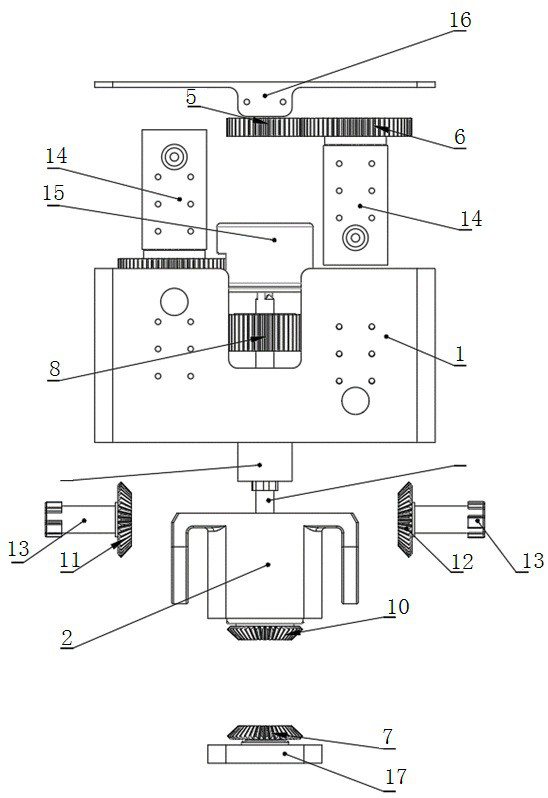

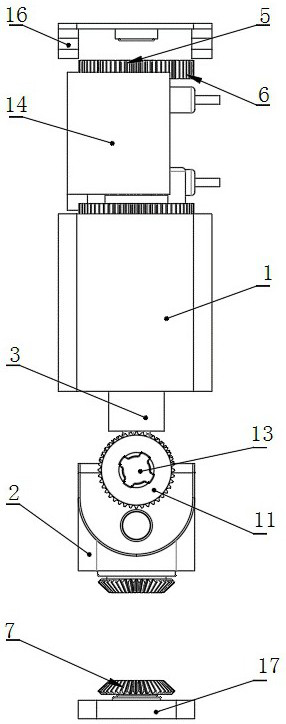

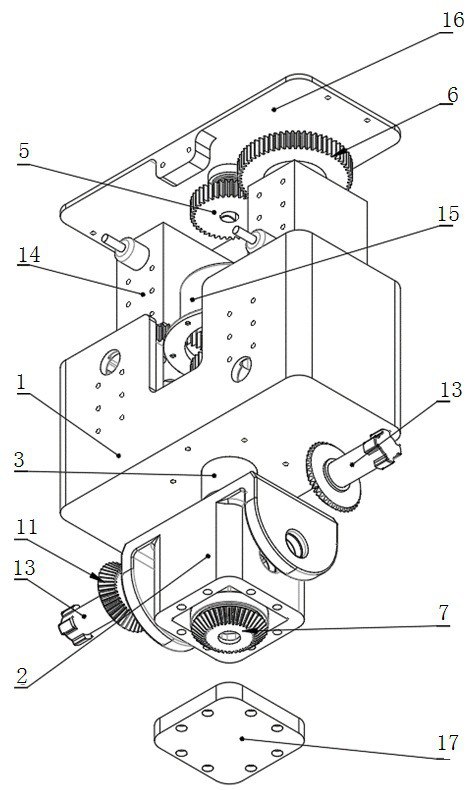

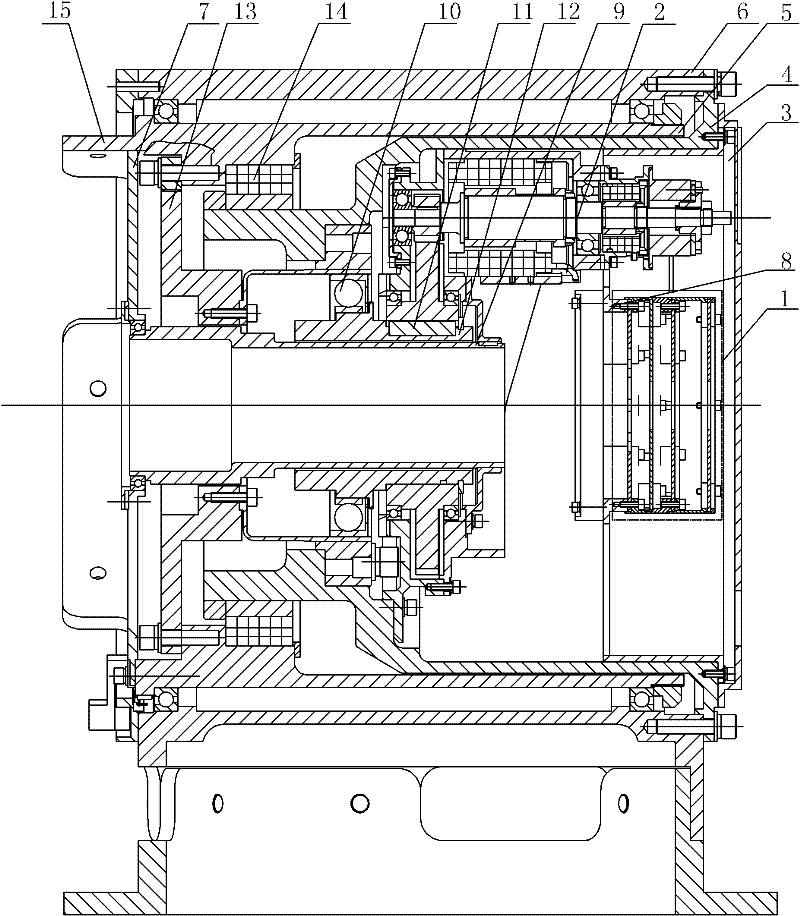

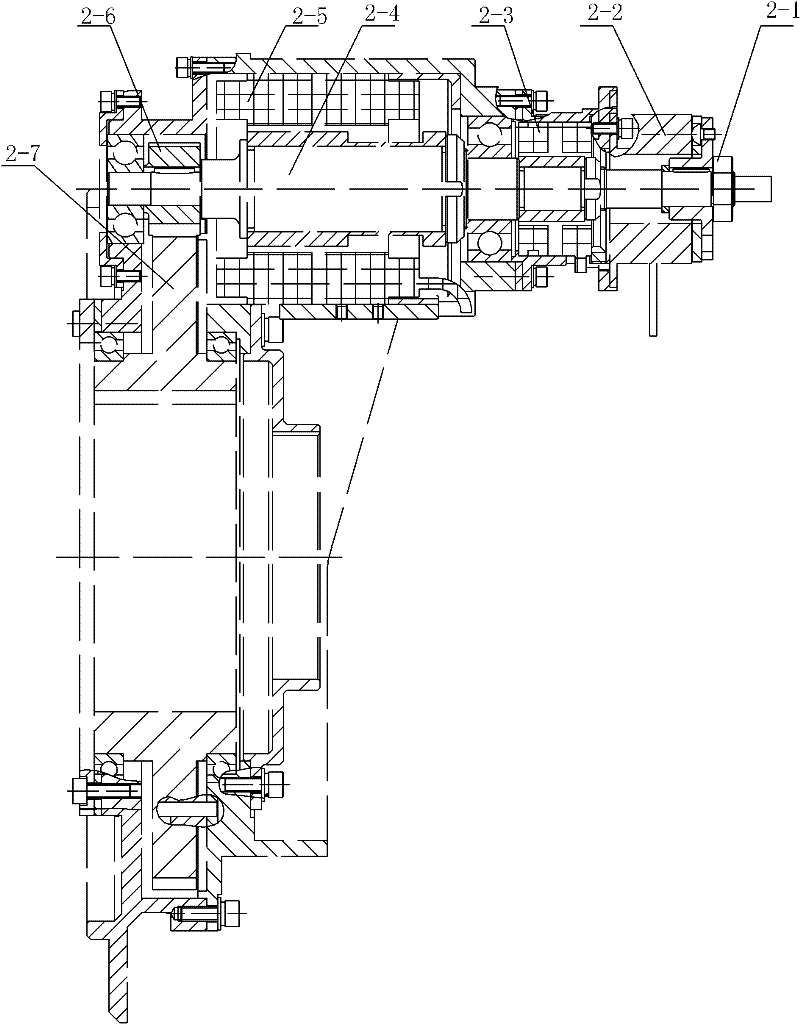

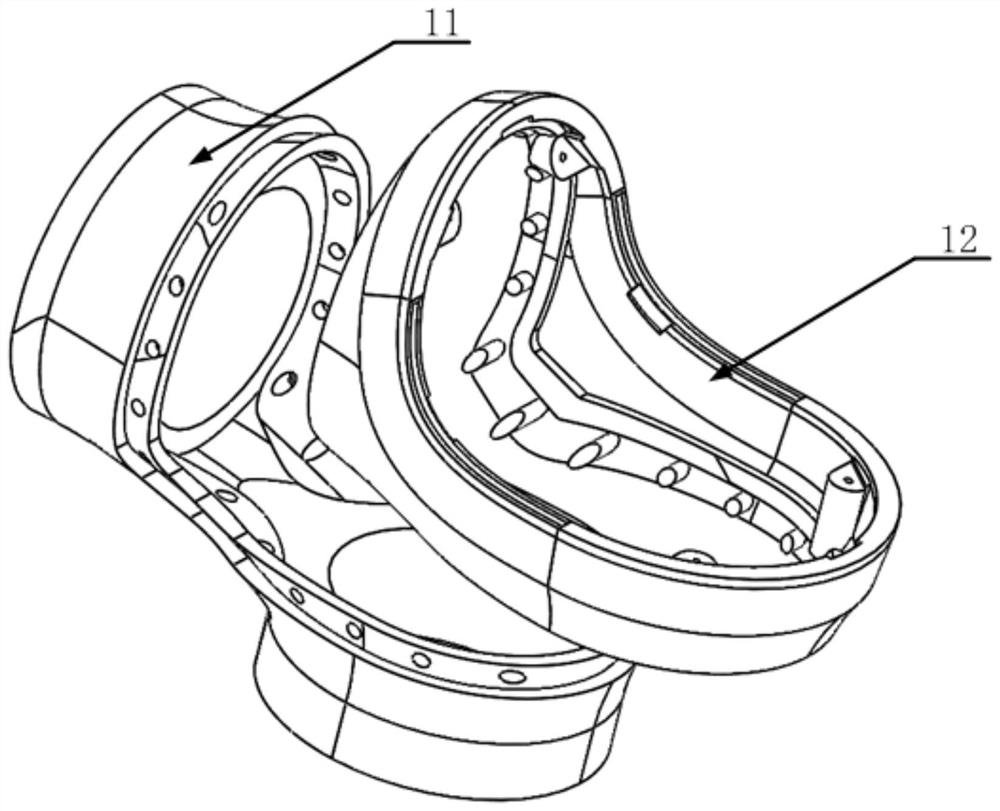

Double-arm robot modularized joint with hollow structure

The invention discloses a double-arm robot modularized joint with a hollow structure, belonging to the field of industrial robots. A mechanical arm is composed of seven similar modularized joints. The joint comprises an input device and an output device, wherein the input device comprises a hollow motor rotor, a rotor axial positioning ring, a third motor bearing, a hollow brake rotor, an O-shaped sealing ring, a motor stator mounting flange, a main transmission shaft, a motor rotor, a second motor bearing, a bearing pressing cover and a harmonic reducer wave generator; the output device comprises a joint output flange, a first output bearing, a mounting flange, an absolute value encoder rotor, a sealing bearing and a harmonic reducer steel wheel; the input device is connected with the output device by the mounting flange. The double-arm robot modularized joint has the advantages that the problems of robot products with more varieties, small batches and complicated structures can be solved; the load dead-weight ratio of the joint can be increased on the basis of meeting the conditions, and the rotation precision of the joint is improved.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

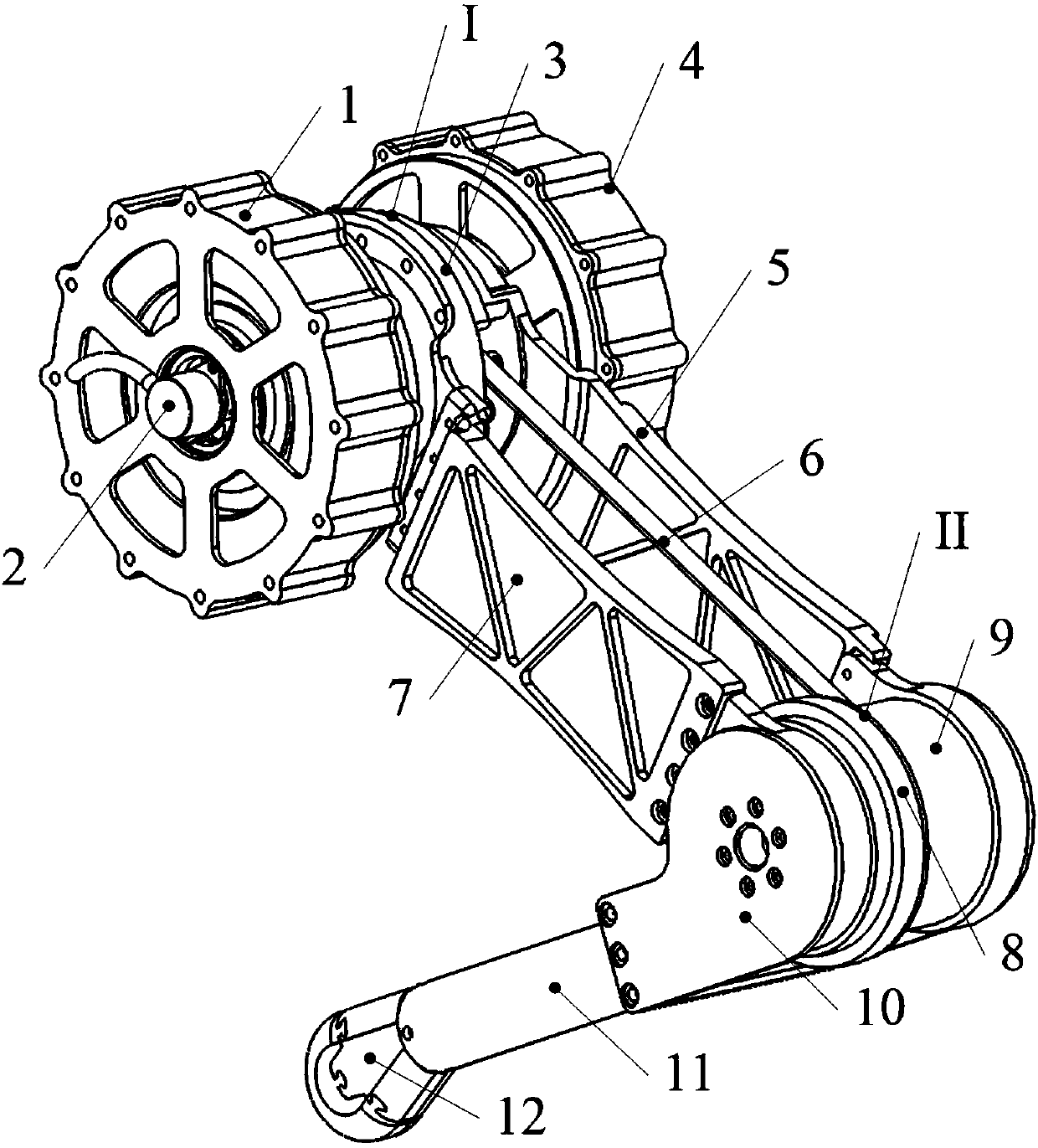

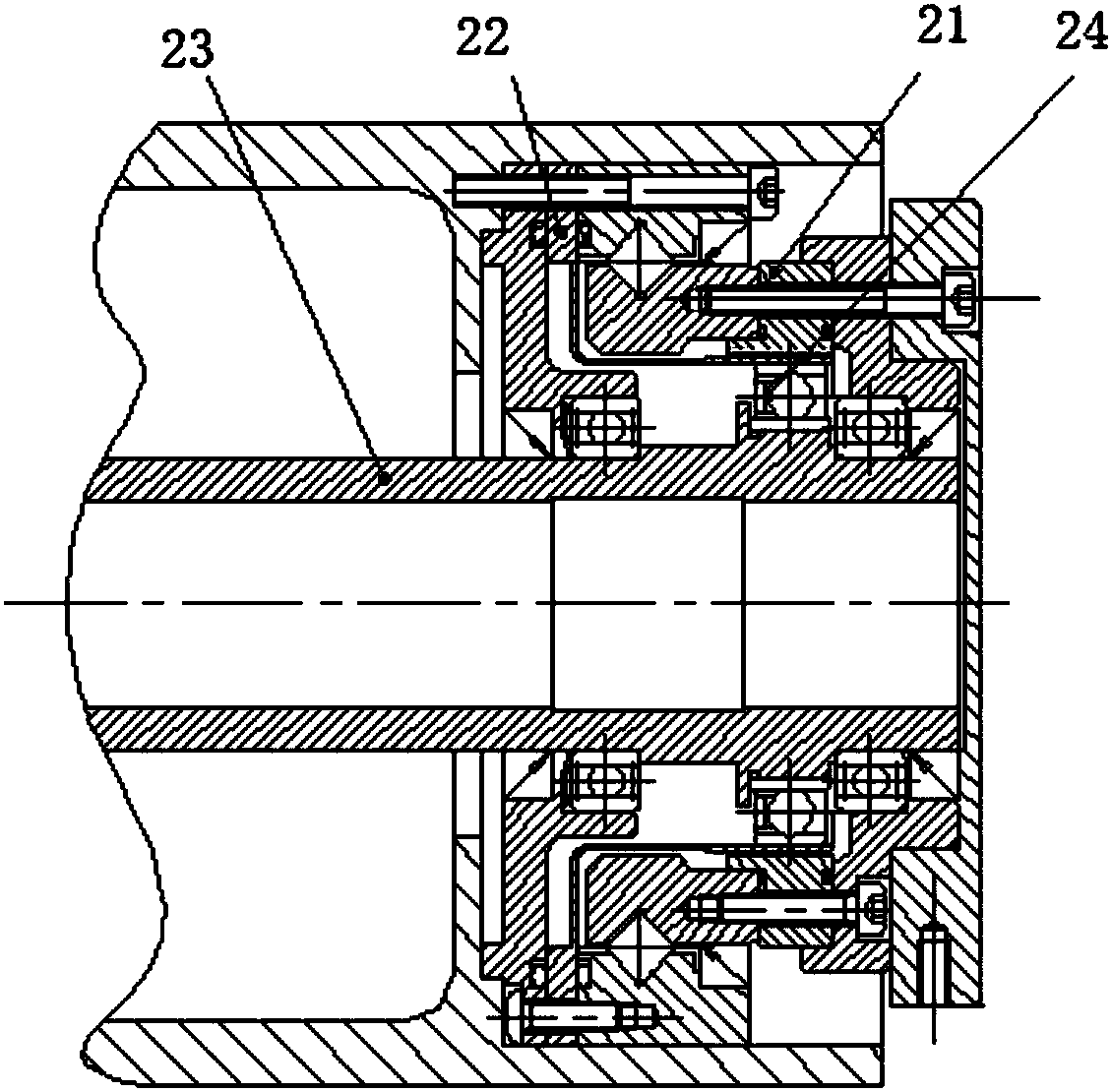

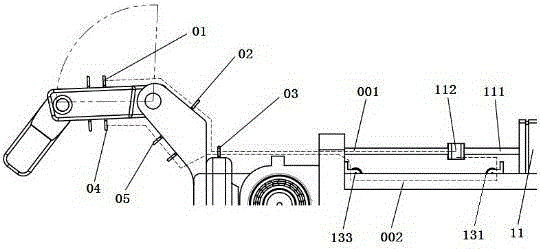

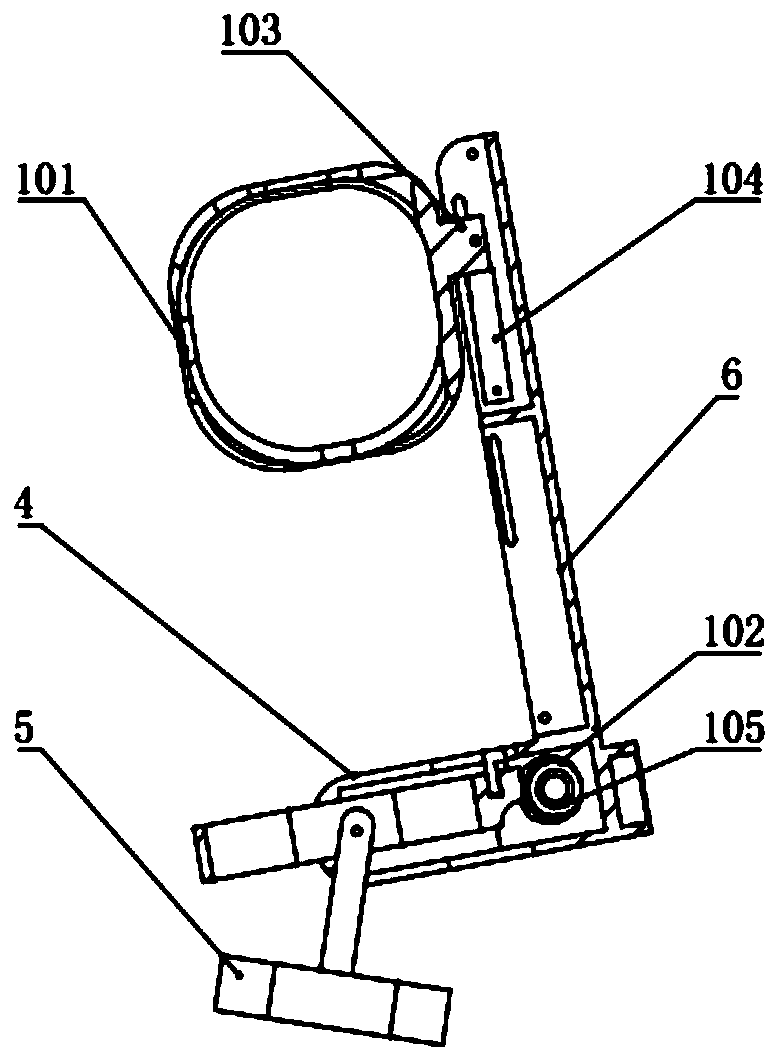

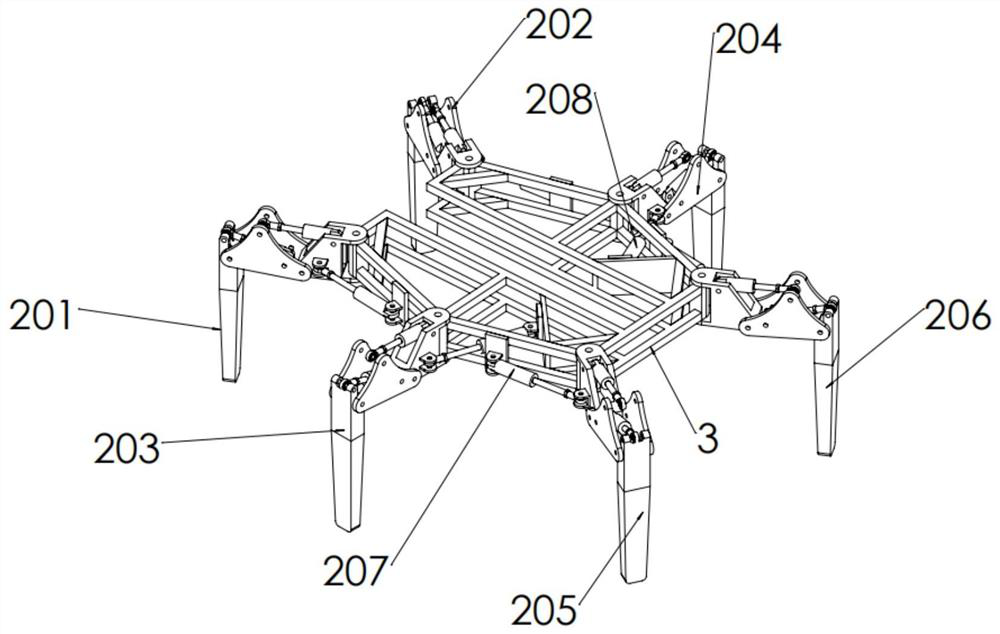

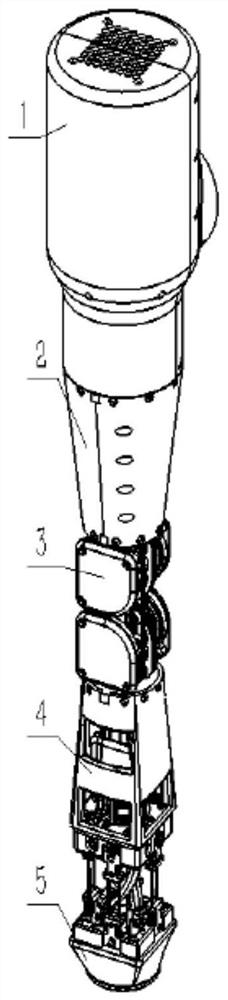

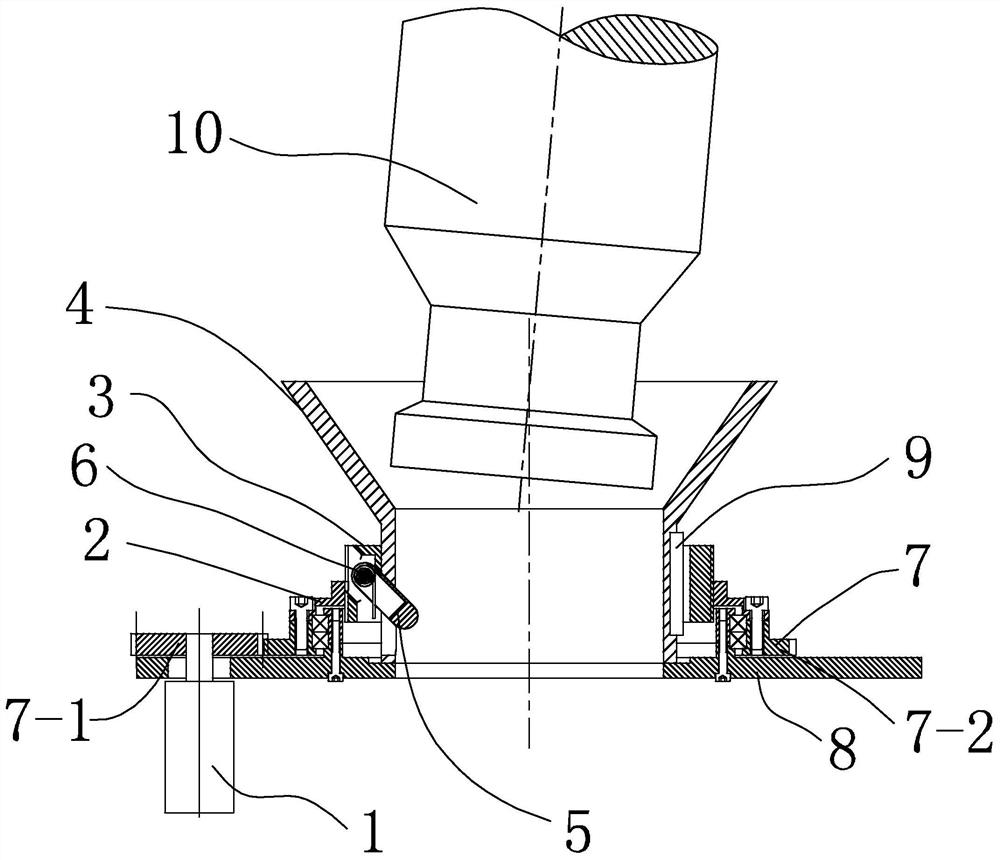

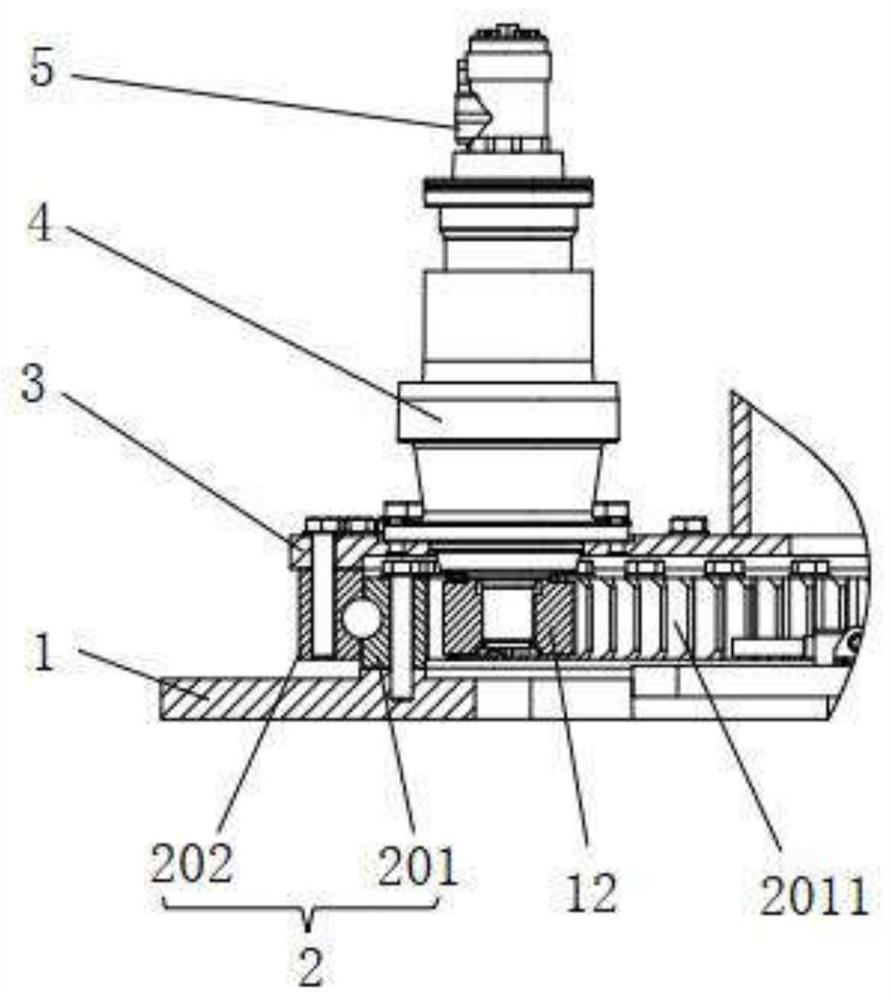

Single leg structure of electric quadruped robot

PendingCN107651041ALight in massSmall moment of inertiaVehiclesThighPhysical medicine and rehabilitation

The invention relates to a single leg structure of an electric quadruped robot. The single leg structure comprises a hip joint, a knee joint, a thigh connecting rod, a shank connecting rod and a foot,the hip joint comprises a first hip joint body and a second hip joint body, the second hip joint body is connected with the power output end of the first hip joint body, the knee joint is connected with the power output end of the first hip joint body through the thigh connecting rod, the knee joint is in rigid connection with the second hip joint body, the power output end of the second hip joint body is connected with power input end of the knee joint through the transmission mechanism, the shank is fixedly connected to the power output end of the knee joint, and the foot is connected to the shank. According to the structure, the low quality and low rotating inertia of the thigh and the shank is guaranteed, the good motion performance is achieved, the structure is simple and compact, itis guaranteed that the knee joint and the hip joint of the single leg have the good reverse drive characteristic, and the single leg structure can be used for assembling the electric quadruped robotwhich is capable of bouncing and high in load deadweight ratio.

Owner:SHANDONG UNIV

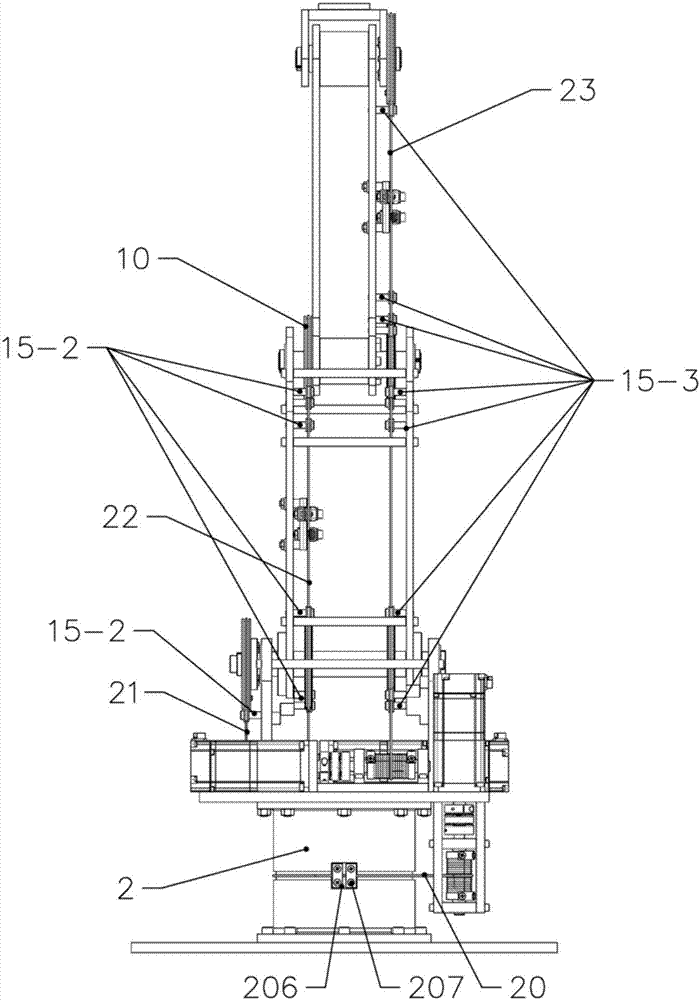

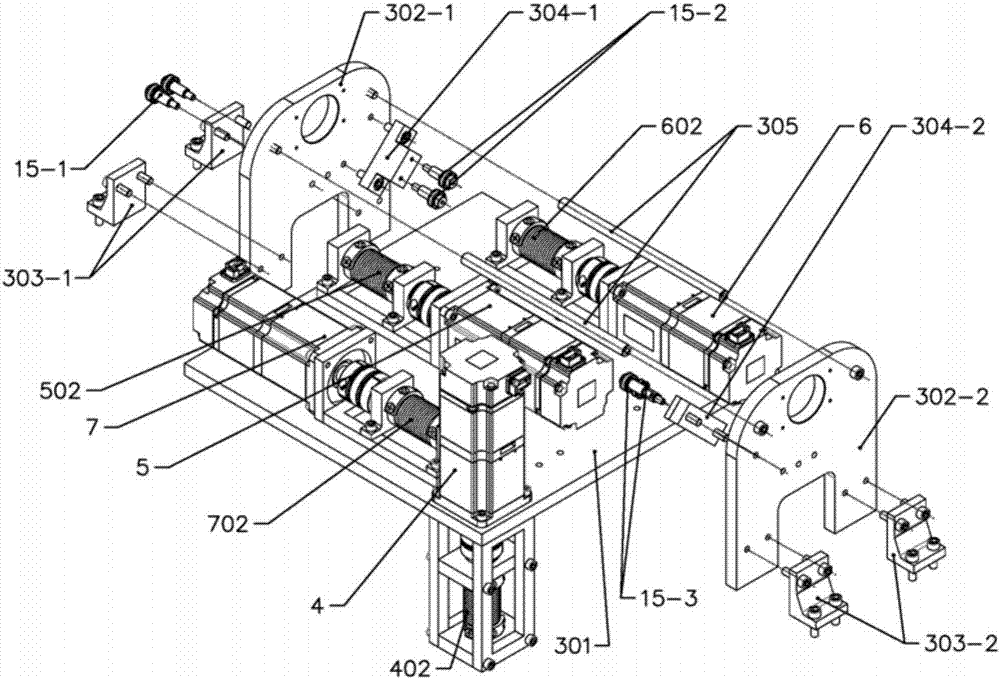

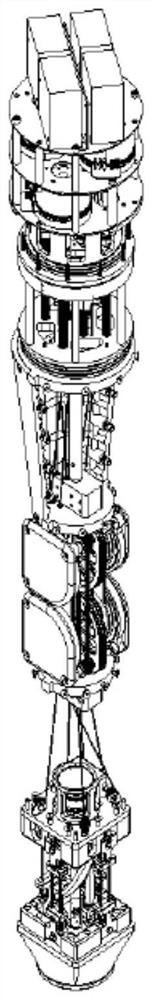

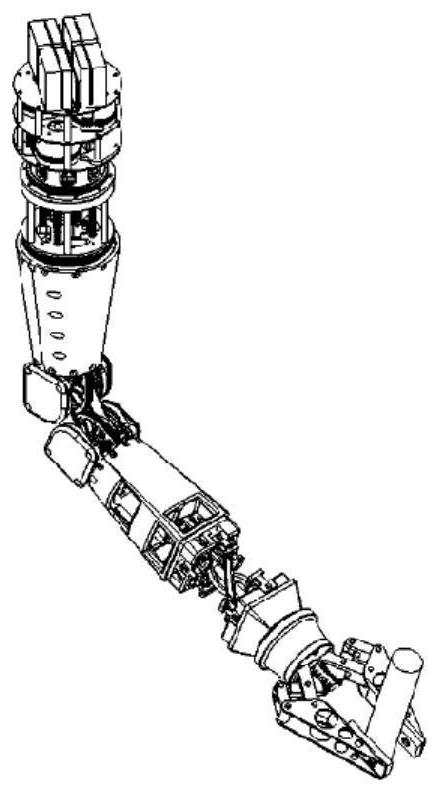

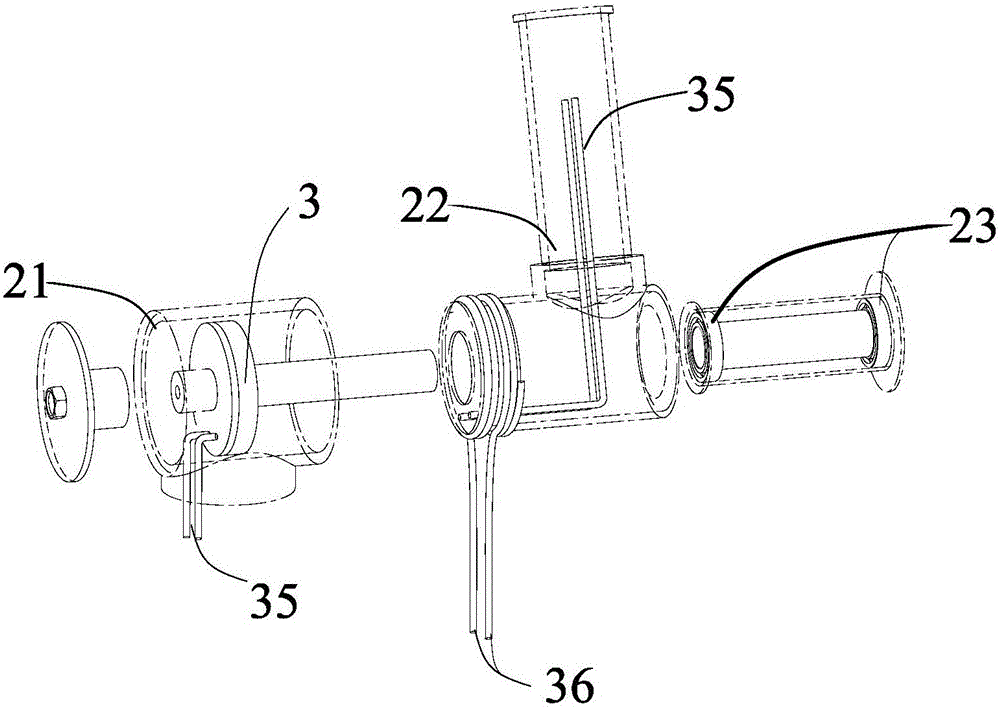

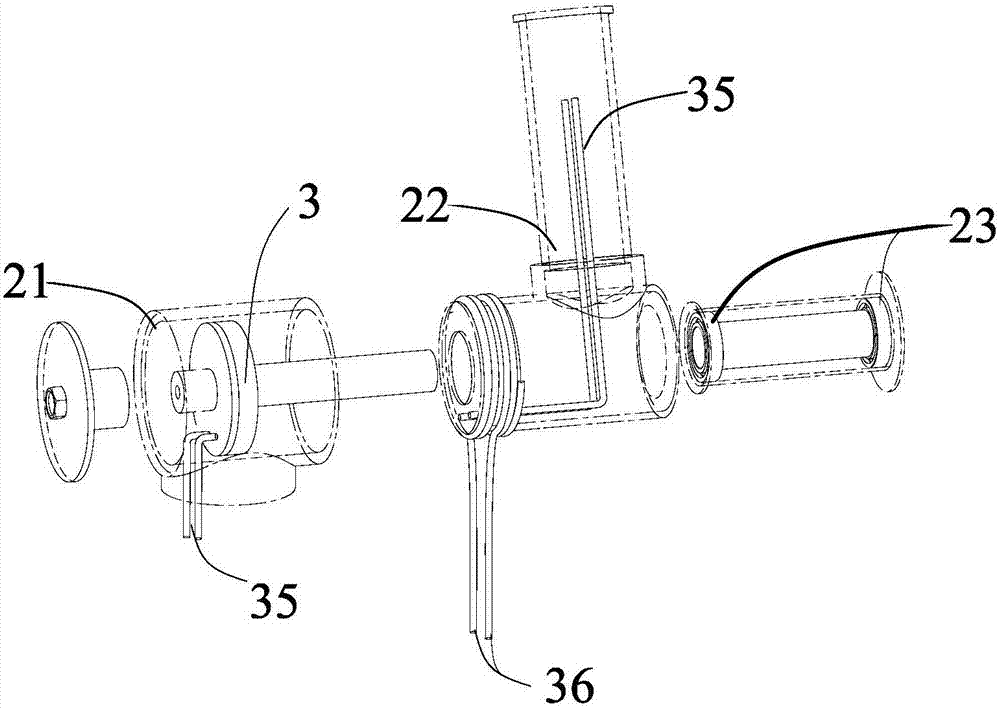

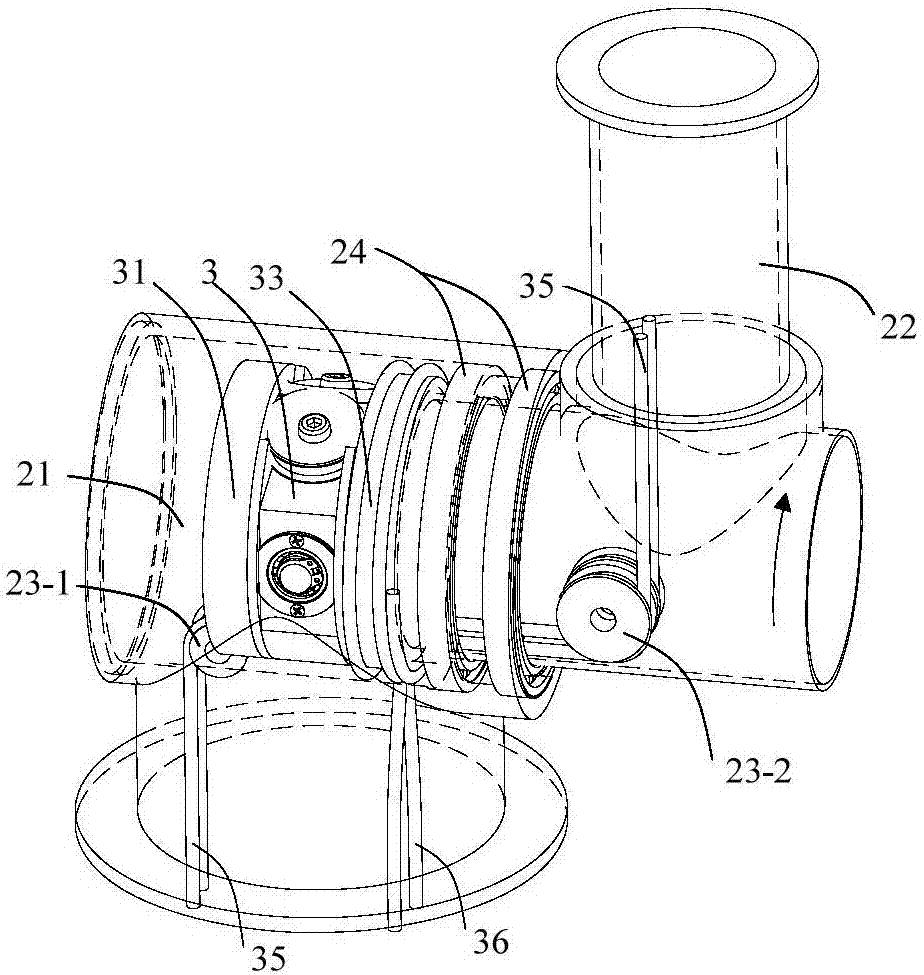

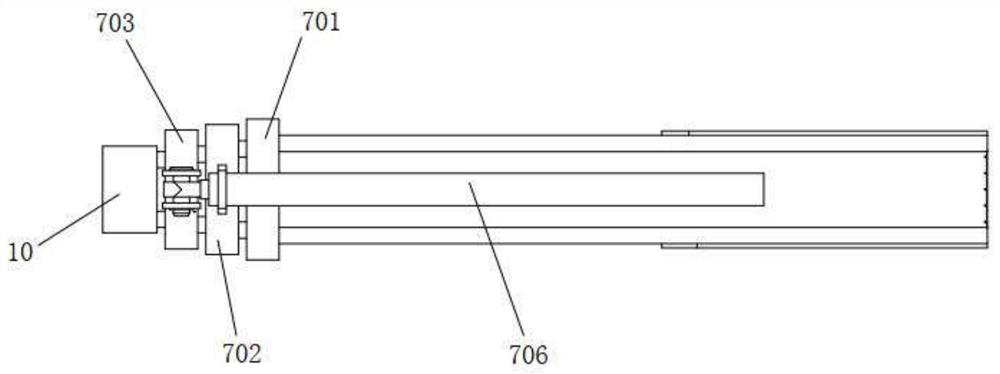

Rope-driven multi-degree-of-freedom series manipulator and driving method thereof

ActiveCN107253182AReduce size and massReduce loadProgramme-controlled manipulatorDrive wheelControl engineering

The invention discloses a rope-driven multi-degree-of-freedom series manipulator and a driving method thereof, and belongs to the field of manipulators. The rope-driven manipulator comprises a base, a waist joint unit, a waist platform, a large arm unit, a small arm unit, a tail end platform unit and the like. One ends of steel wire ropes are fixed to driven wheels at joints, the other ends of the steel wire ropes are fixed to a driving unit winch at the waist platform, so that the driving force is transferred from the winch at the waist platform to the driven wheels at the joints at the rear end by means of the ropes and accordingly drives the joint units to conduct rotation movement around joint shafts correspondingly. The joint driving ropes are guided by guide pulleys and bypass the joint shafts at the front end sequentially, by arranging the specified diameters of shaft guide wheels, a driving method is built, thus any joint at the front end of the manipulator rotates while the posture of the tail end of the manipulator remains unchanged relative to the world coordinate system. The buffer effect of making contact of the manipulator with the environment is increased through the flexibility of the ropes, and the rope-driven multi-degree-of-freedom series manipulator is especially suitable for occasions with the high requirements for the interaction safety of the manipulator, people and the environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

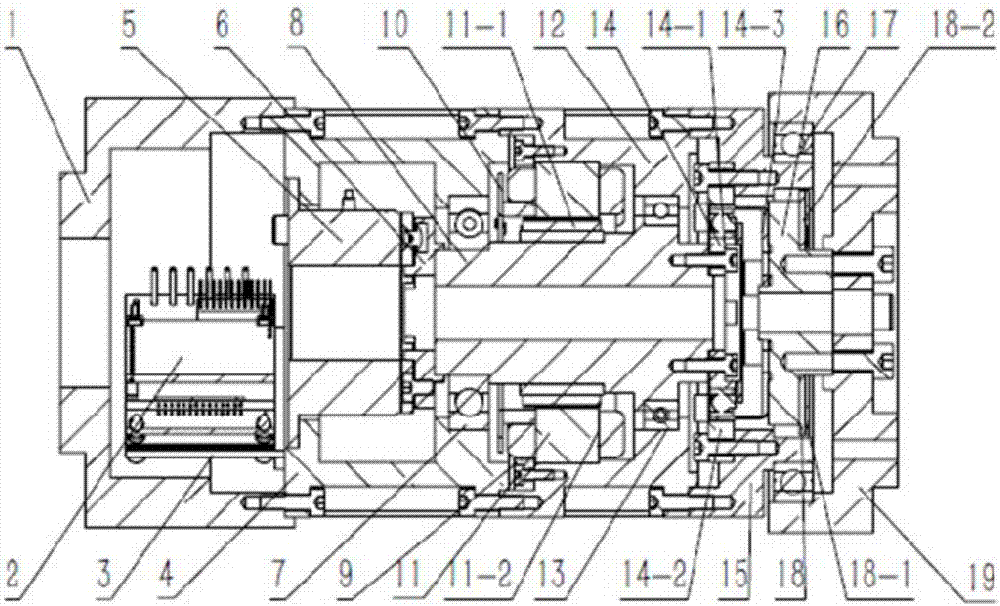

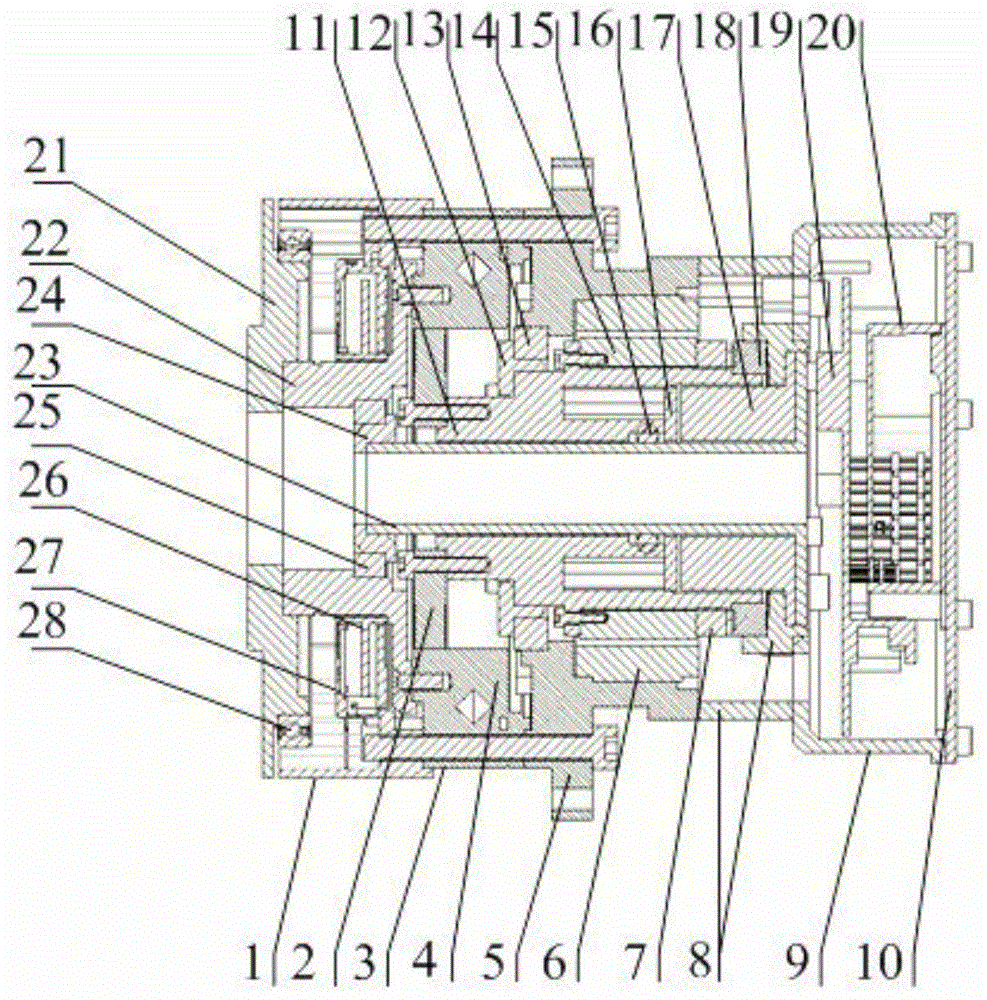

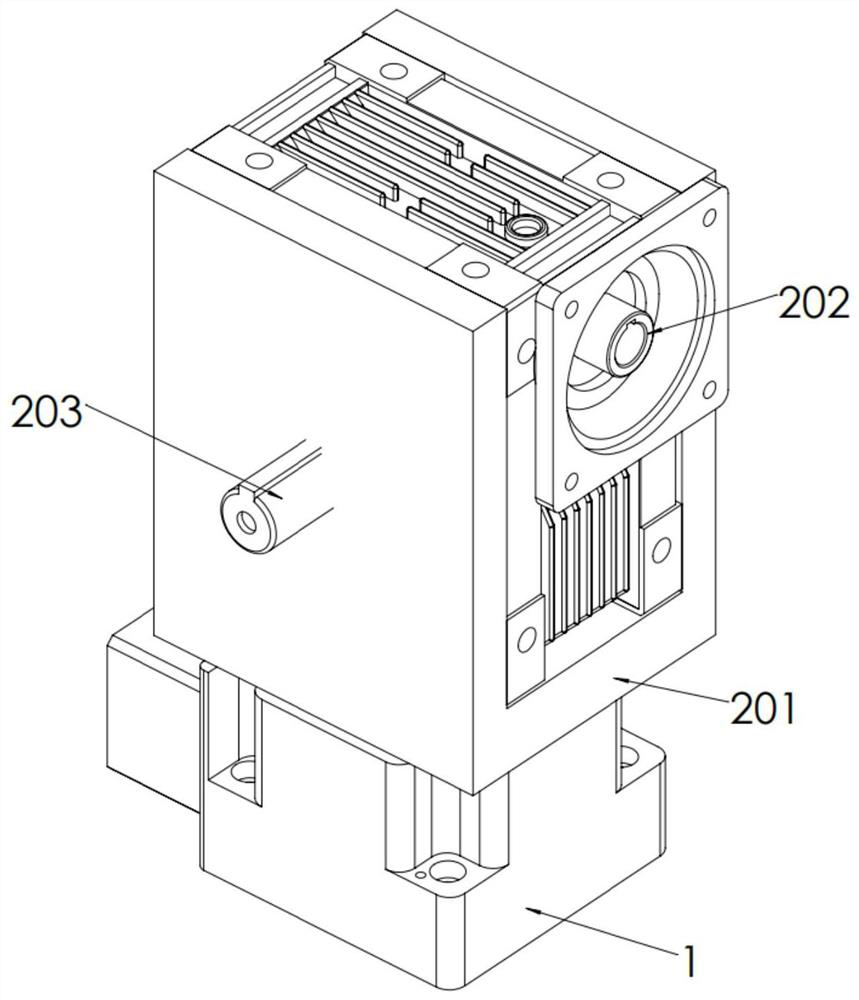

Mechanical arm modular joint with redundant degree of freedom

The invention discloses a mechanical arm modular joint with a redundant degree of freedom. The mechanical arm modular joint with the redundant degree of freedom comprises a joint fixing part, a power assembly and an electric part; the joint fixing part comprises a joint fixing end cover, a driver bracket, a brake fixing outer shell, a motor fixing outer shell and a harmonic speed reducer fixing outer shell; the power assembly comprises a joint permanent magnetic brake, a hollow transmission shaft, a direct-current servo motor, a harmonic speed reducer, a harmonic speed reducer output connecting flange and a joint output end cover; the electric part comprises a driver bracket, a joint driver, a Hall sensor and an absolute optical encoder. The mechanical arm modular joint with the redundant degree of freedom disclosed by the invention is compact in design and small in size, and meanwhile, is light in weight, high in integration level, and high in load-to-weight ratio.

Owner:SUZHOU UNIV

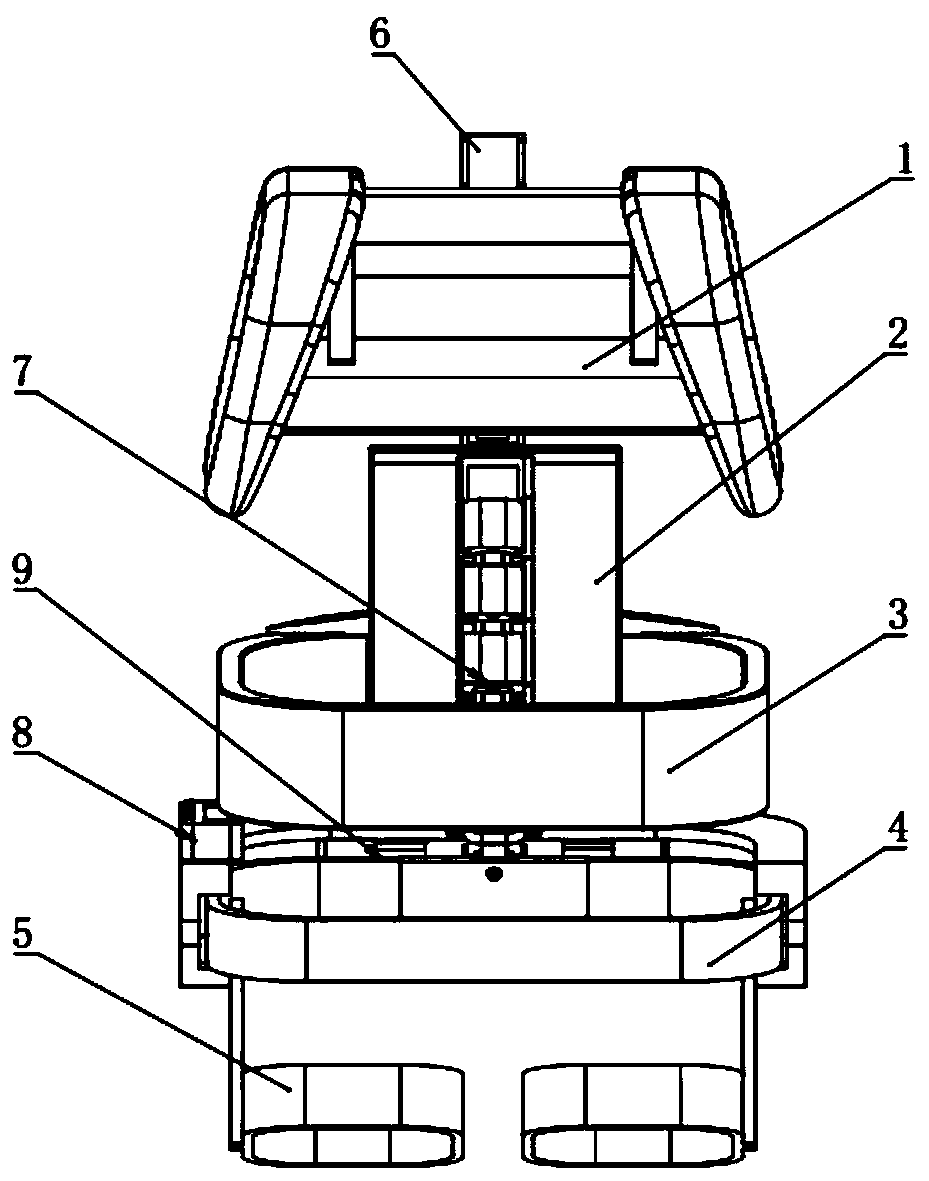

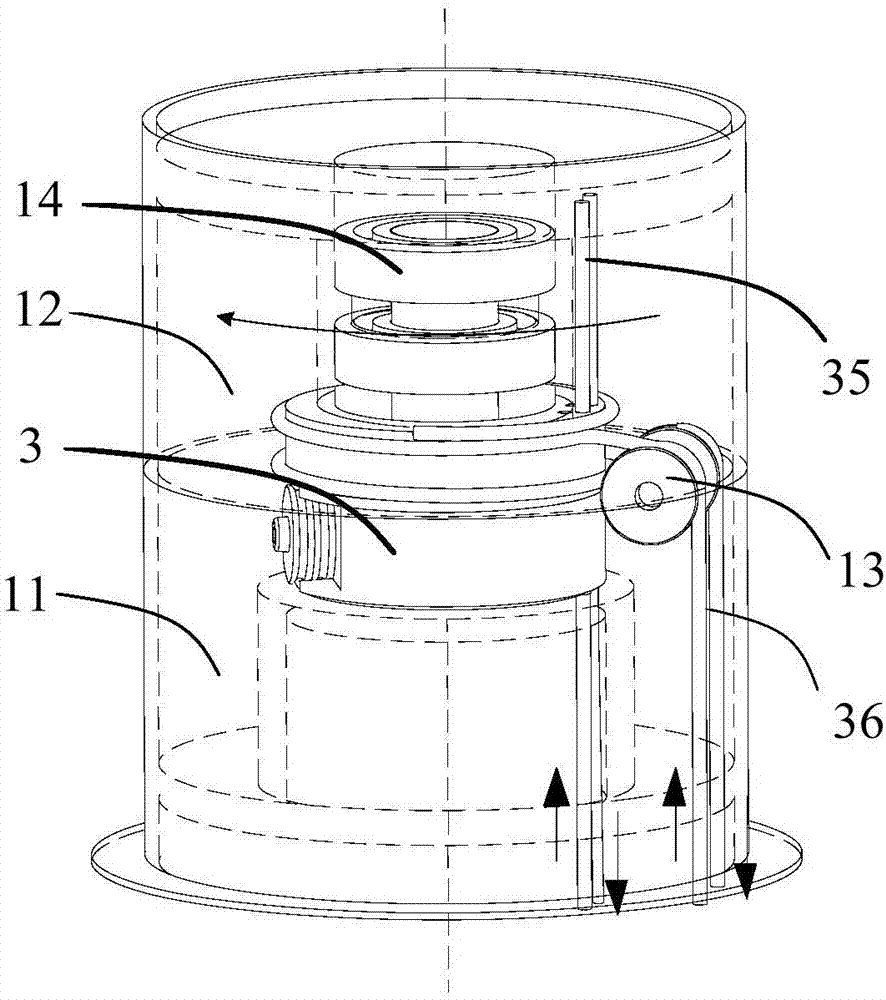

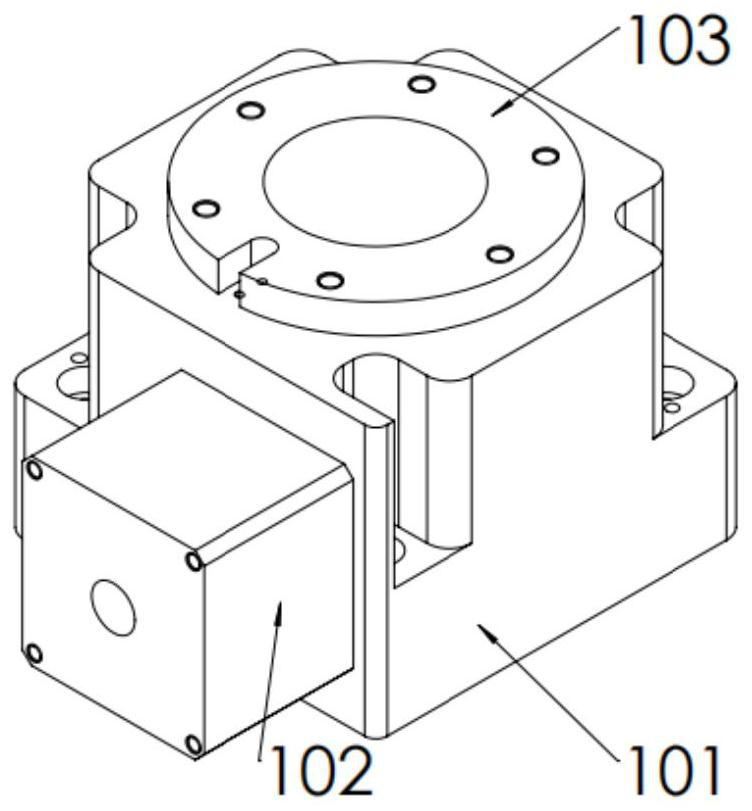

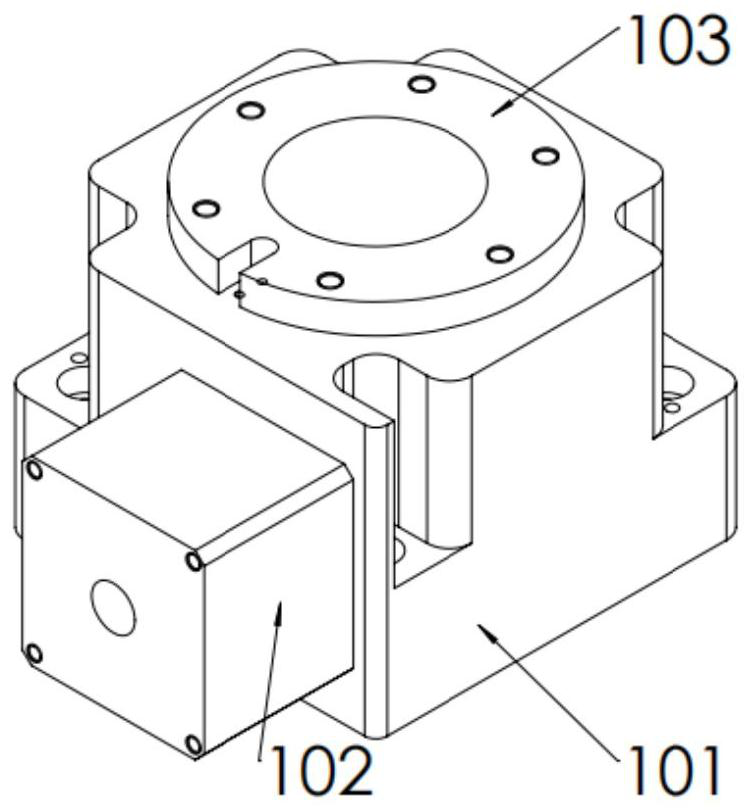

Integrated robot joint module

PendingCN108247668ASave construction spaceSimple transmission structureJointsMechanical energy handlingDrive motorIntegrated circuit

The invention provides an integrated robot joint module. The integrated robot joint module comprises a joint output component, a harmonic reducer, a joint shell, a driving motor main body, a brake mechanism and an integrated circuit module; the joint output component is used for being connected with an external execution mechanism or a load; the harmonic reducer is used for adjusting the rotatingspeed of the joint output component; the joint shell is used for fixing the harmonic reducer and driving the motor main body, the brake mechanism and the integrated circuit module, and the driving motor main body is used for driving the harmonic reducer according to the instruction of the integrated circuit module; the brake mechanism is used for holding the driving motor main body according to aninstruction of the integrated circuit module; and the integrated circuit module drives the working state of the motor main body according to an instruction of an external upper computer, and the working state of the joint output component is used for driving the driving motor main body.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

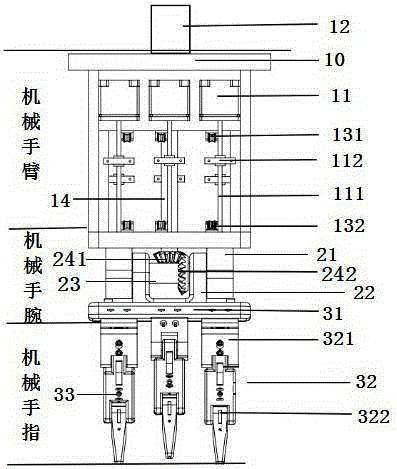

Flexible bionic manipulator

ActiveCN105291134AHigh degree of flexibilityImprove the quality of useProgramme-controlled manipulatorJointsRobotic armFinger joint

The invention discloses a flexible bionic manipulator and relates to the technical field of mechanical devices. The flexible bionic manipulator comprises a mechanical arm, a mechanical wrist and a mechanical finger component. The mechanical arm comprises an arm support, first motors and a second motor, and the first motors and the second motor are connected with screw rods through rotating shafts. Nuts are mounted on the screw rods through threaded fit. The mechanical finger component comprises a mounting base, finger units are arranged on the mounting base, and each finger unit comprises three finger knuckles which are connected through two finger joints. The finger joints are connected to the nuts of the screw rods through steel wires respectively. According to the mechanical wrist, a connecting shaft connects a first rotating seat on the arm support and a second rotating seat on the finger mounting base, and the mechanical wrist further comprises a gear set in meshing transmission, wherein a first bevel gear is synchronous with a rotary shaft of the second motor, and a second bevel gear is fixedly connected to the connecting shaft in a sleeving mode. The flexible bionic manipulator is high in bionic degree, the grabbing force and grabbing postures can be autonomously adjusted, the ratio between the grabbing force and the dead weight is high, and the requirement for loads of an industrial robot body is lowered.

Owner:FOSHAN GUANGDONG TECH UNIV CNC EQUIP TECH DEV +1

Mechanical arm and mechanical arm joint

PendingCN107685341ACompact structureSmall form factorProgramme-controlled manipulatorJointsManipulatorEngineering

The invention discloses a mechanical arm joint. The mechanical arm joint comprises a motor end input and brake part, a motor driving part, a decelerator part and a joint output part which are sequentially arranged in the axial direction of a motor of the joint. The motor end input and brake part comprises a motor end brake, a motor end coder and a first shell, wherein the motor end brake is located on one side of the input end of a split type hollow torque motor and arranged on a hollow shaft of the motor in a sleeving mode, the motor end brake is sleeved with the motor end coder, and the first shell contains the motor end brake and the motor end coder. A connector is connected with the motor end brake and the motor end coder together respectively.

Owner:前元运立(北京)机器人智能科技有限公司

Lightweight lumbar auxiliary rehabilitation exoskeleton robot

ActiveCN110101544ASave construction spaceSimple transmission structureChiropractic devicesBack supportRehabilitation training

The invention provides a lightweight lumbar auxiliary rehabilitation exoskeleton robot. The lightweight lumbar auxiliary rehabilitation exoskeleton robot comprises a back spinal traction mechanism, aspinal lumbar bionic mechanism, a spinal lumbar driving mechanism, an intelligent adjustable elastic waistband, an abdominal fixing supporting mechanism, a spinal rehabilitation exoskeleton leg fixingmechanism, a back supporting mechanism, a spinal exoskeleton handheld terminal and a driving control box, wherein the spinal lumbar driving mechanism moves along the back supporting mechanism under the control of the driving control box to cause the bionic deformation of the spinal lumbar bionic mechanism, thereby driving a wearer to achieve traction exercise training of the lumbar front and rearflexion and extension; the back spinal traction mechanism moves up and down under the control of the driving control box, so that the effect is achieved that human body load above the lumbar vertebrae is transmitted to the spinal exoskeleton leg fixing mechanism through the back supporting mechanism and the abdominal fixing supporting mechanism, and the wearer achieves the rehabilitation trainingof the vertical lumbar traction. The lightweight lumbar auxiliary rehabilitation exoskeleton robot adopts integrated design, has a smaller volume, improves the load-to-weight ratio, and achieves intelligent wearable and multi-pose rehabilitation training.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Integrated joint module of compact robot and compact robot

PendingCN108032330AReduce axial sizeImprove carrying capacityProgramme-controlled manipulatorJointsCollision detectionControl engineering

The invention provides an integrated joint module of a compact robot and the compact robot, and relates to the technical field of robots. The integrated joint module comprises a single cycloidal pin wheel speed reducer, a shell, a shaft, an electromagnetic actuator, a movable pin, an integrated circuit module, an end cover, a cable protection sleeve, a claw brake disc, a cable, a photoelectric encoder read head, a photoelectric encoding disc, a motor stator and a motor rotor. The single cycloidal pin wheel speed reducer is fixed to the front end of the shell, the motor stator is fixed in the shell, and the motor rotor is fixedly connected with the shaft. The front end of the shaft is fixedly connected with the input end of the single cycloidal pin wheel speed reducer. The rear end of the shaft is sequentially fixedly connected with the photoelectric encoding disc and a brake device. The photoelectric encoder read head is fixed in the shell and is opposite to the photoelectric encodingdisc in position, and the end cover is fixed to the rear end of the shell. The integrated joint module of the compact robot and the compact robot are high in integrity, small in size, large in load dead load ratio and good in rigidity, the structure is hollow, collision detection is conducted, and design, installation, usage and maintenance of the robot are easier and more convenient.

Owner:HEFEI HIT PRECISION TRANSMISSION CO LTD

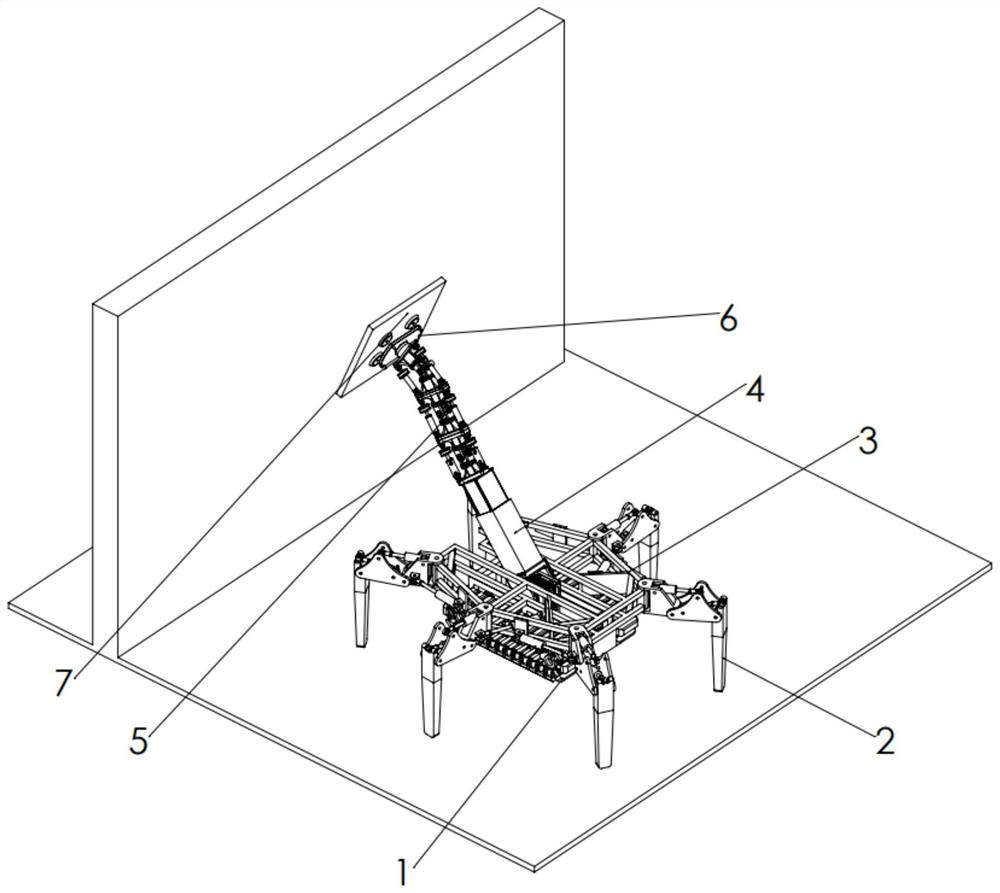

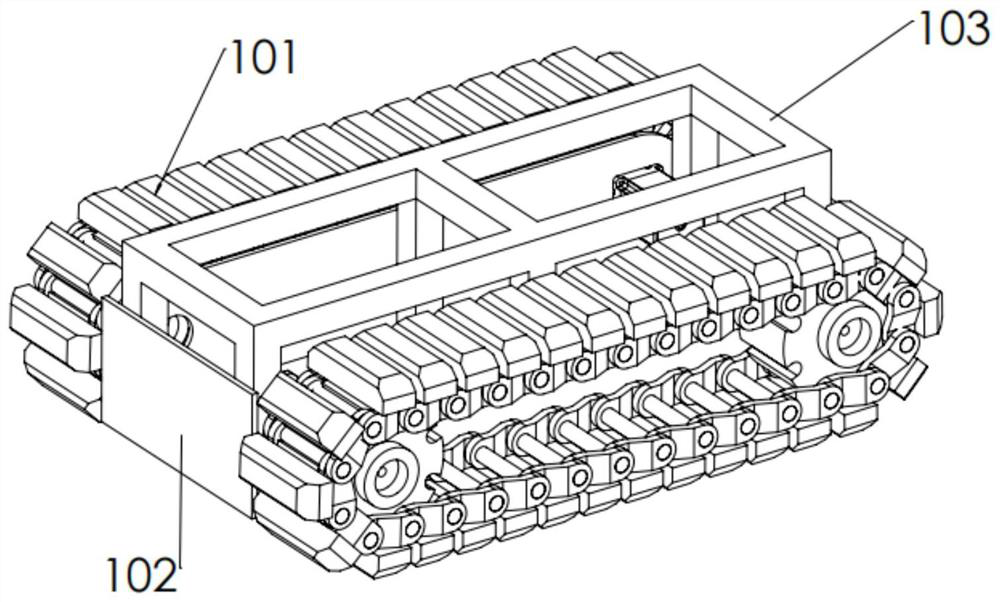

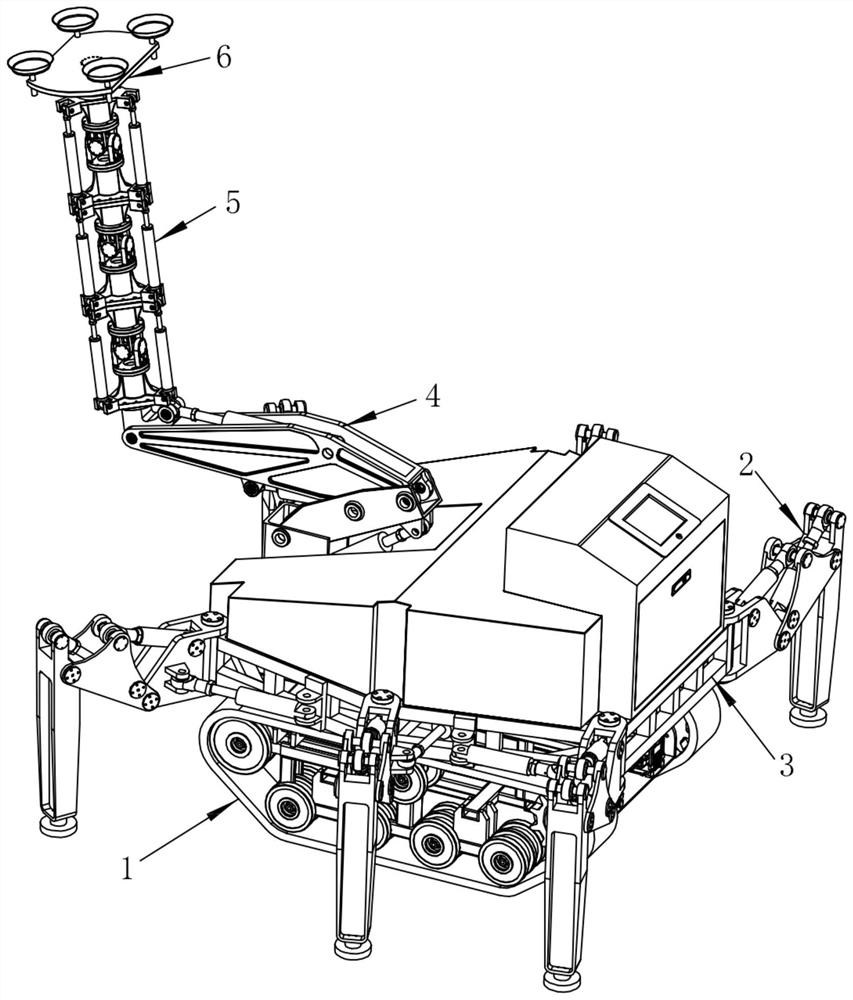

Six-foot crawler-type parallel hydraulic building curtain plate mounting robot

InactiveCN112606919ALight weightHigh load ratioProgramme-controlled manipulatorJointsRemote controlControl engineering

The invention belongs to the technical field of robot structures, and relates to a six-foot crawler-type parallel hydraulic building curtain plate mounting robot which is composed of a crawler-type moving platform, a mechanical six-foot assembly, a leg mounting frame, a mechanical large arm assembly, a hydraulic small arm assembly, a curtain plate terminal executing mechanism and a curtain plate. The mechanical six-foot assembly is installed on the leg mounting frame. The leg mounting frame is installed on the crawler-type moving platform, the mechanical large arm assembly is installed on the crawler-type moving platform, the hydraulic small arm assembly is installed on the mechanical large arm assembly, the curtain plate terminal executing mechanism is installed on the hydraulic small arm assembly, and the curtain plate is attracted to the curtain plate terminal executing mechanism. The curtain plate is grabbed by the curtain plate terminal executing mechanism through an air pressure sucker, so that the curtain plate is stably and effectively grabbed, the mounting cost is reduced, and the mounting efficiency is improved; the remote control over the robot can be achieved, the 5G data transmission technology is utilized, monitoring and action control over a building curtain plate installation construction site are achieved, and the installation process is more intelligent and efficient.

Owner:SHENZHEN INST OF ADVANCED TECH

Bionic rope-driven four-degree-of-freedom arm for man-machine cooperation

ActiveCN112476478AImprove environmental adaptabilityReduce weightJointsArmsUniversal jointMan machine

The invention discloses a bionic rope-driven four-degree-of-freedom arm for man-machine cooperation. The degree of freedom of an elbow joint is one, and the degree of freedom of a wrist joint is three. All joints are driven in a rope transmission mode, the elbow joint is achieved through a tangent circle rolling mechanism, meanwhile, a movable pulley transmission structure is designed to achieve joint rigidity and torque amplification, and three degrees of freedom of the wrist joint are achieved through cooperation of a three-connecting-rod parallel mechanism and an universal joint. All jointdriving motors are arranged at shoulder structures, so that the motion inertia of the arm is effectively reduced, and the rope length change between the joints is decoupled and is convenient to control. Compared with an existing motor-driven cooperative robot, the arm has the advantages of being high in movement flexibility, high in movement flexibility, small in movement inertia, large in load self-weight ratio and the like, and the safety coefficient and the working performance of the robot in the field of man-machine cooperation are effectively improved.

Owner:UNIV OF SCI & TECH OF CHINA

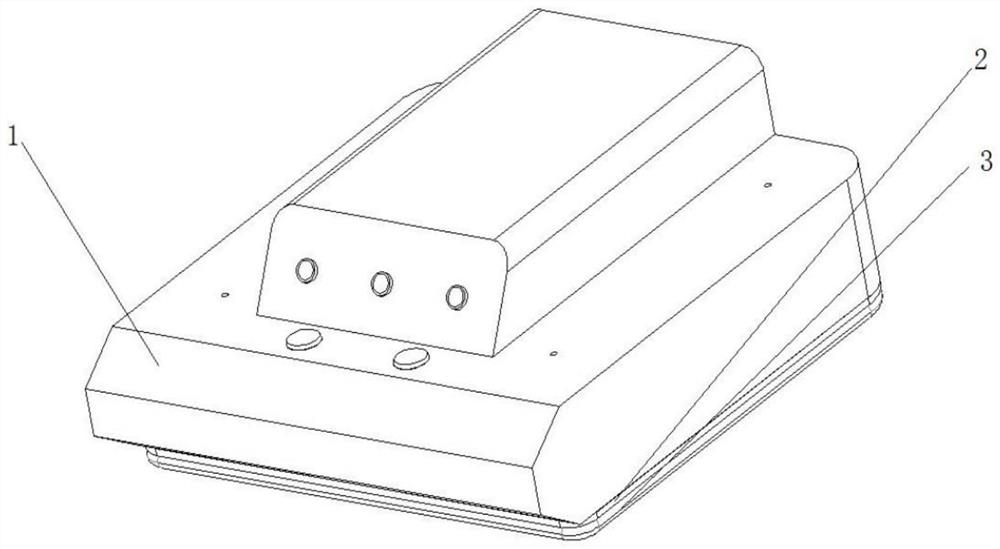

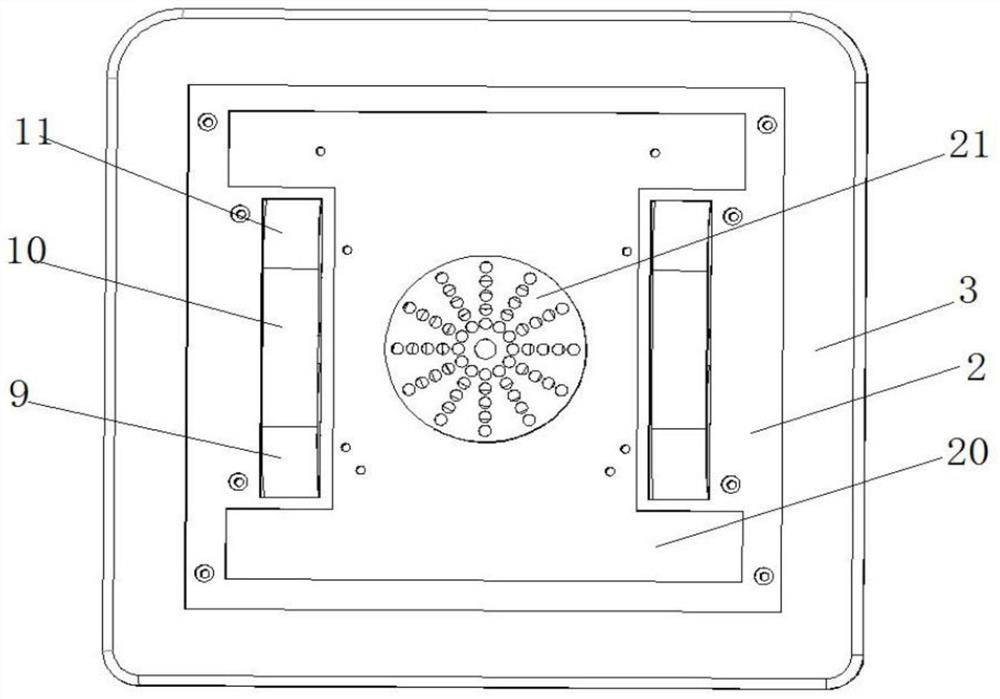

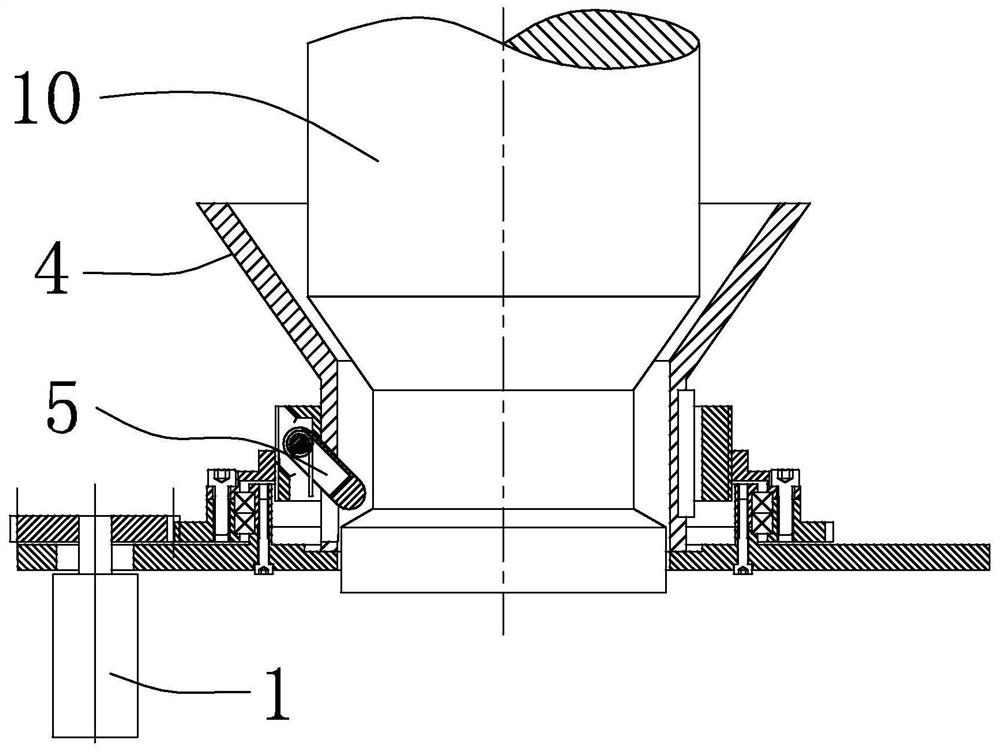

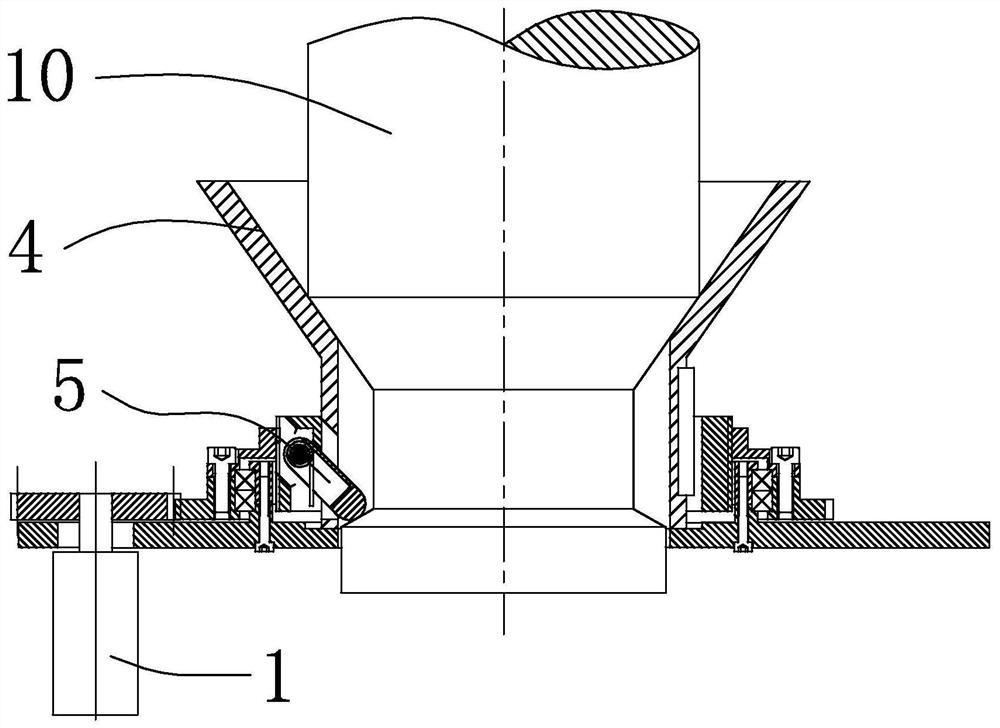

Low-noise negative-pressure wall-climbing robot

PendingCN111845995AReduce overall weightReduce volumePropulsion by batteries/cellsVehicular energy storageElectric machineryClimbing robots

The invention discloses a low-noise negative-pressure wall-climbing robot. The robot comprises a chassis, a moving device, a negative pressure device, a noise reduction device, a main control panel and a monitoring camera device. The negative pressure device is fixed to the top of the chassis, the noise reduction device is arranged at the top of the negative pressure device, two tracks of the moving device are symmetrically installed on the lower surface of the chassis and located on the two sides of the negative pressure device, the tracks driven by the motor make contact with the wall face,and a sealing strip is pasted to the edge of the lower surface of the chassis. The monitoring camera device is installed on the upper surface of the chassis, the main control panel is connected with the remote control device through wireless signals, and the main control panel is in electric signal connection with the moving device, the negative pressure device, the noise reduction device and themonitoring camera device. The low-noise negative-pressure wall-climbing robot has the advantages of being low in noise, small in size, light in weight, stable in operation and the like. The cable-freecontrol can be realized, monitoring and detecting equipment can be carried, the investigation and detection task can be excellently completed in a narrow space, and the working efficiency is greatlyimproved.

Owner:GUANGDONG INST OF INTELLIGENT MFG

A dual-arm robot modular joint with hollow structure

The invention discloses a hollow structure double-arm robot modular joint used in the field of industrial robots. The mechanical arm is composed of seven similar modular joints. The joint includes: an input device and an output device. The input device includes: hollow motor rotor, rotor axial positioning ring, second motor bearing, hollow brake rotor, O-ring, motor stator mounting flange, main drive shaft, motor rotor, first motor bearing, bearing Gland and harmonic reducer wave generator; the output device includes: joint output flange, output bearing, mounting flange, absolute encoder rotor, sealed bearing and harmonic reducer steel wheel; the input device and The output device is connected through a mounting flange. The advantage of the invention is that it can solve those robot products with many varieties, small batches and complex structures, and increase the load-to-weight ratio of the joints on the basis of satisfying the above conditions, and improve the rotation accuracy of the joints.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

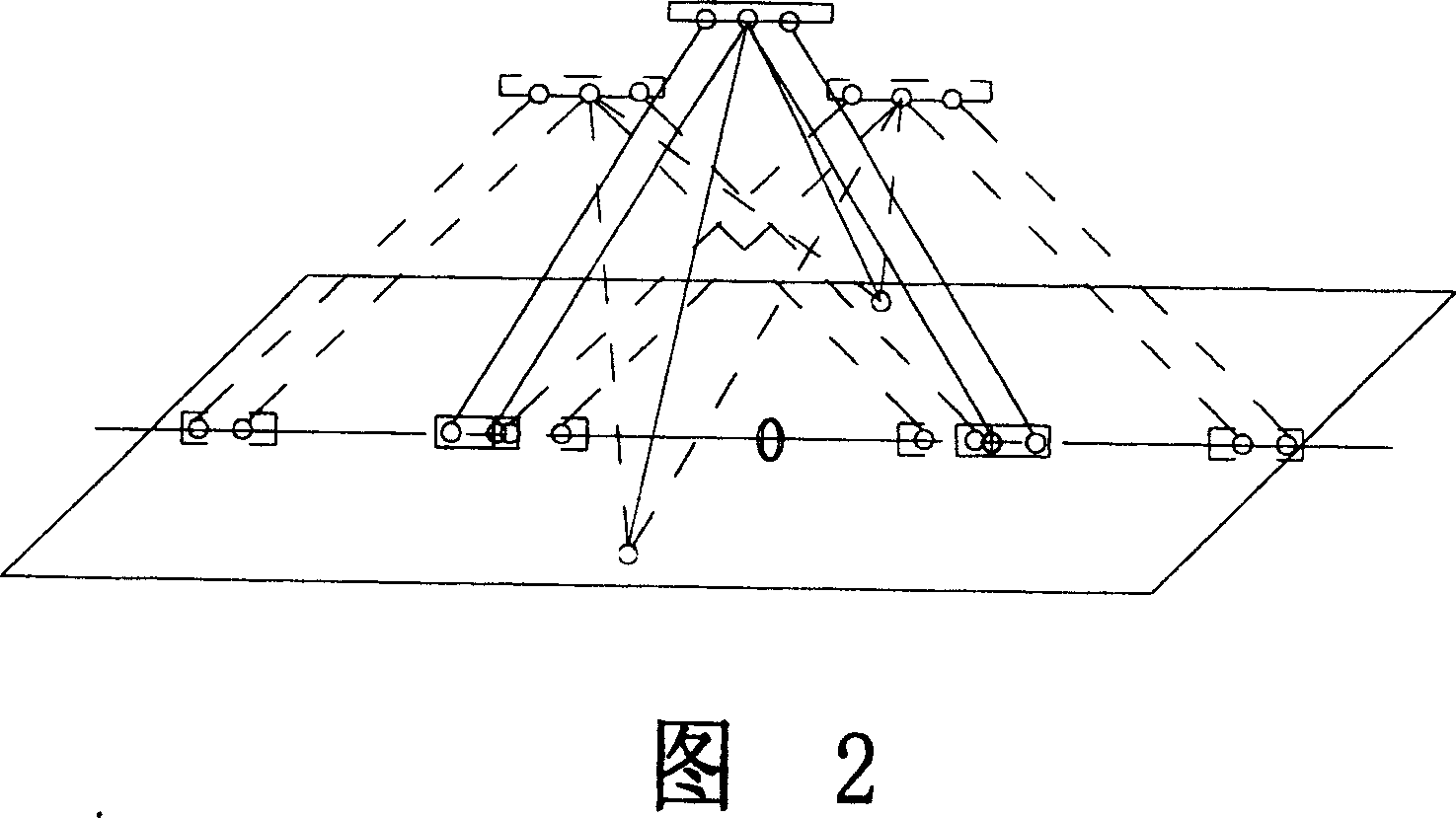

Two-freedom parallel-connecting mechanism with passive constrained branch

InactiveCN100344418CStable postureRealize two degrees of freedom movementProgramme-controlled manipulatorControl theoryLoad bearing

A two-freedom parallel mechanism with passive constraint branches is composed of movable platform, static platform with slots and parallel to movable platform, the two groups of length-fixed active branches and two telescopic passive constraint branches for linking both platforms, and the leading screws with serve motor and slide block and arranged in said slots on static platform. Said active branches and passive constraint branches are linked with both platforms respectively via pin and slide block or ball socket. Its advantages are high lateral load bearing power and no couple between active and passive branches.

Owner:ZHEJIANG UNIV OF TECH

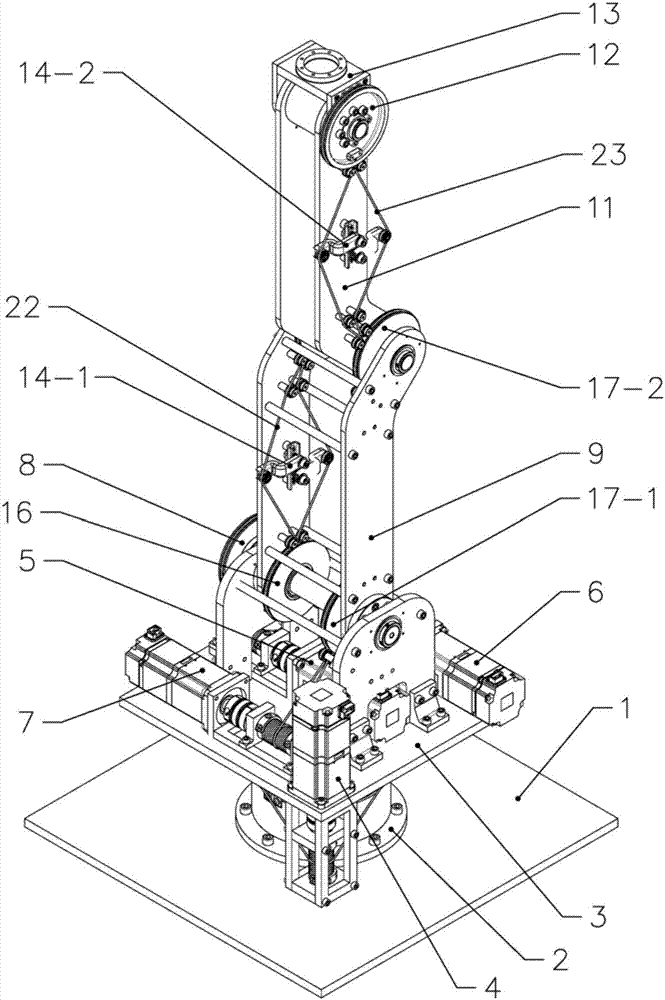

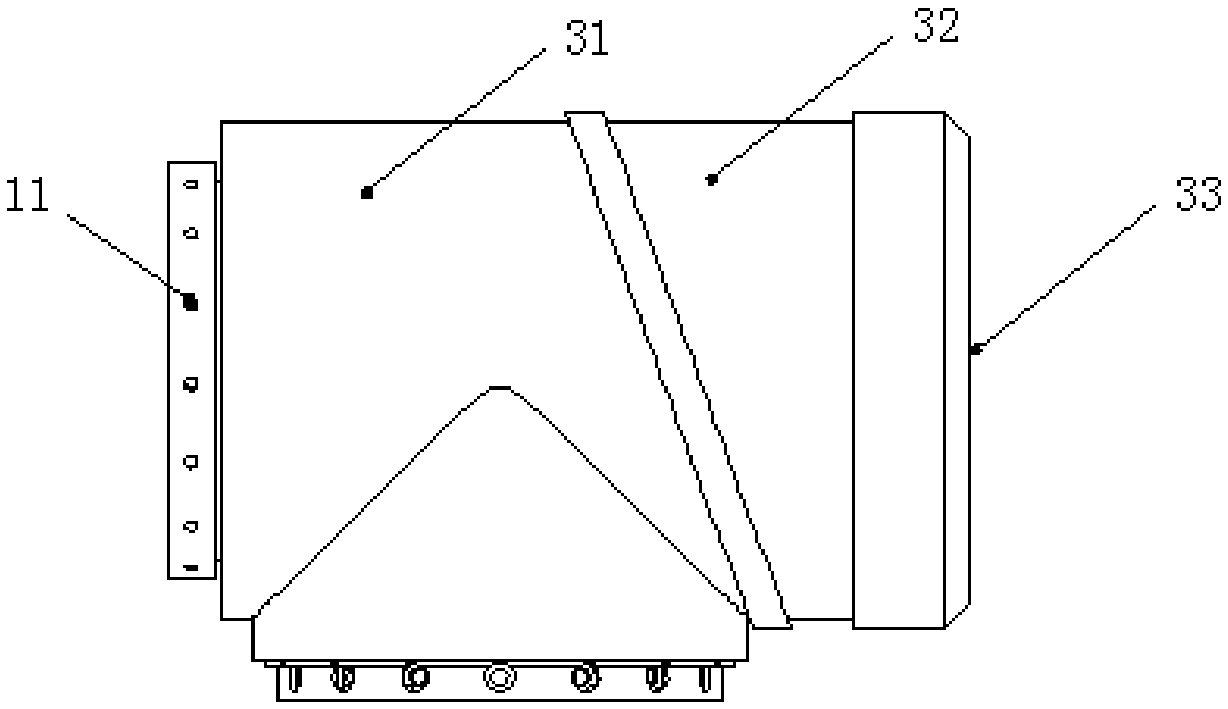

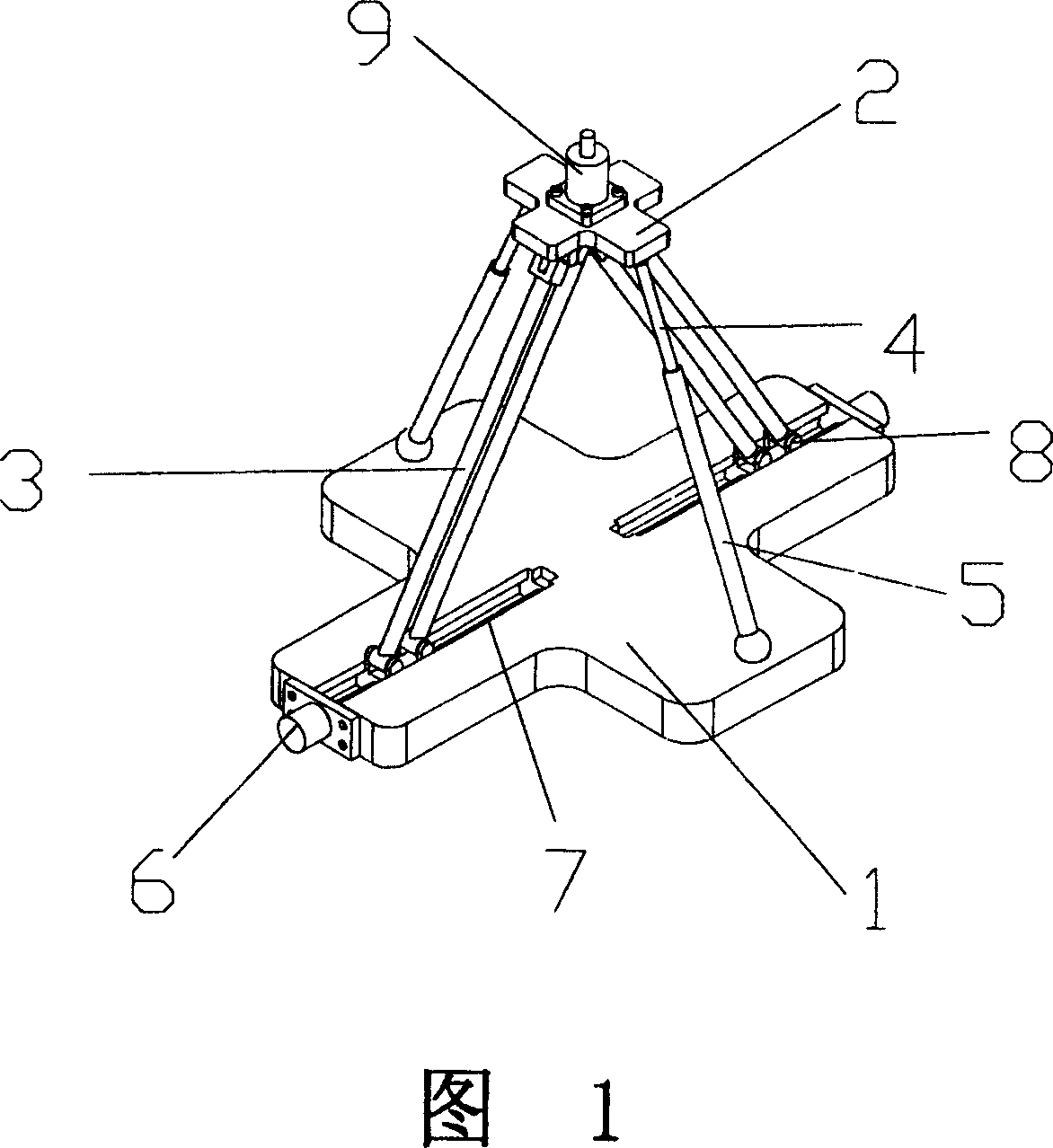

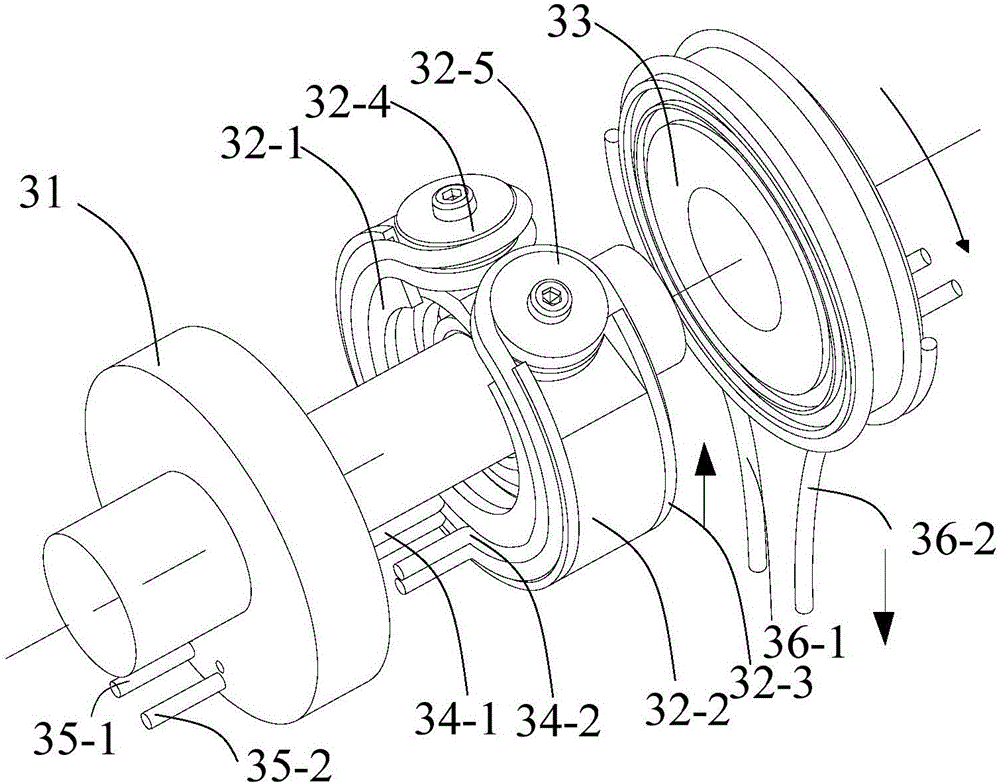

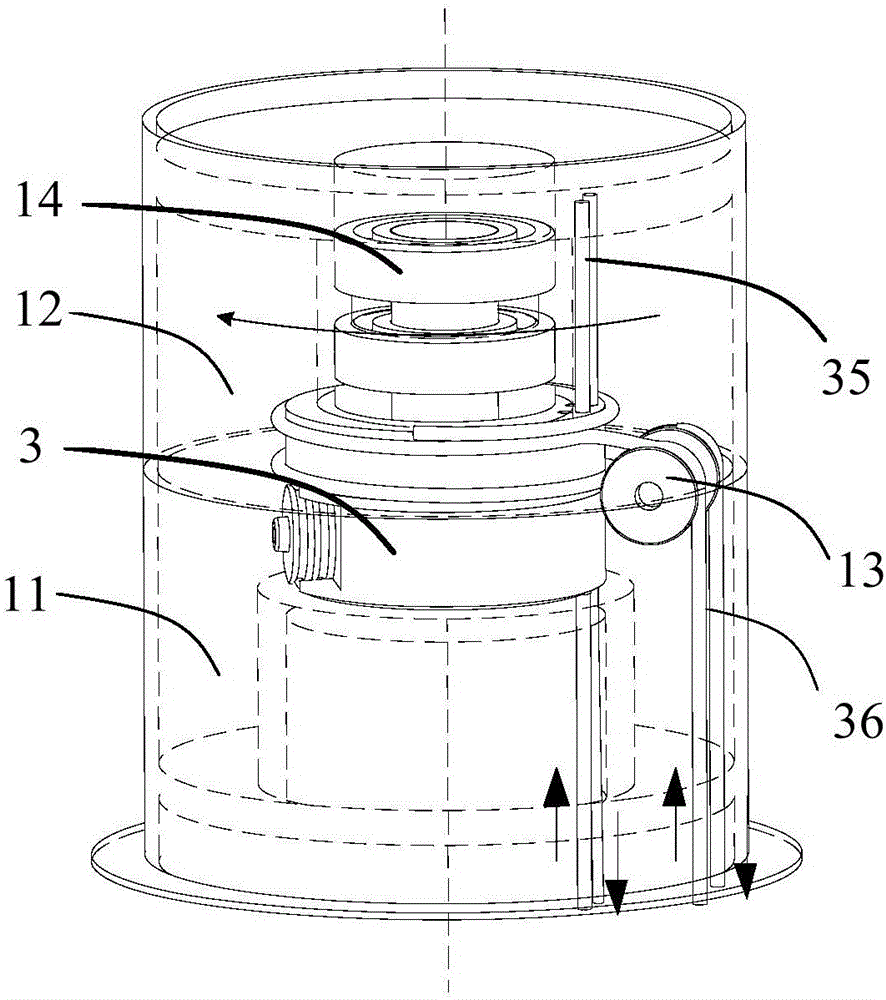

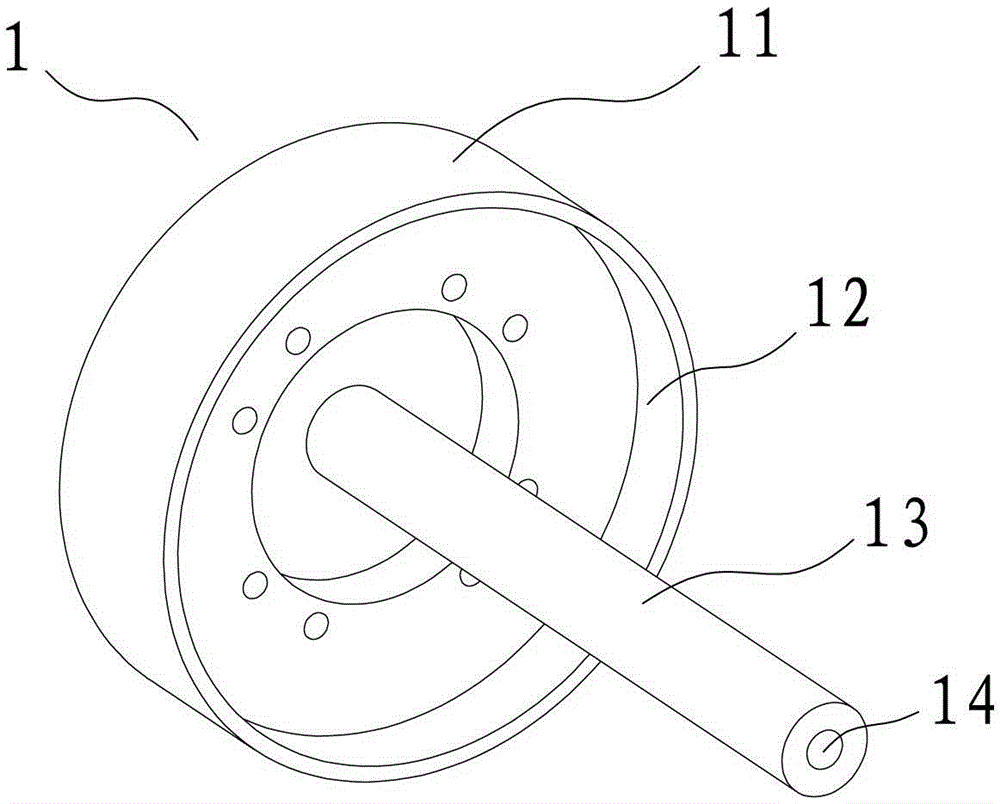

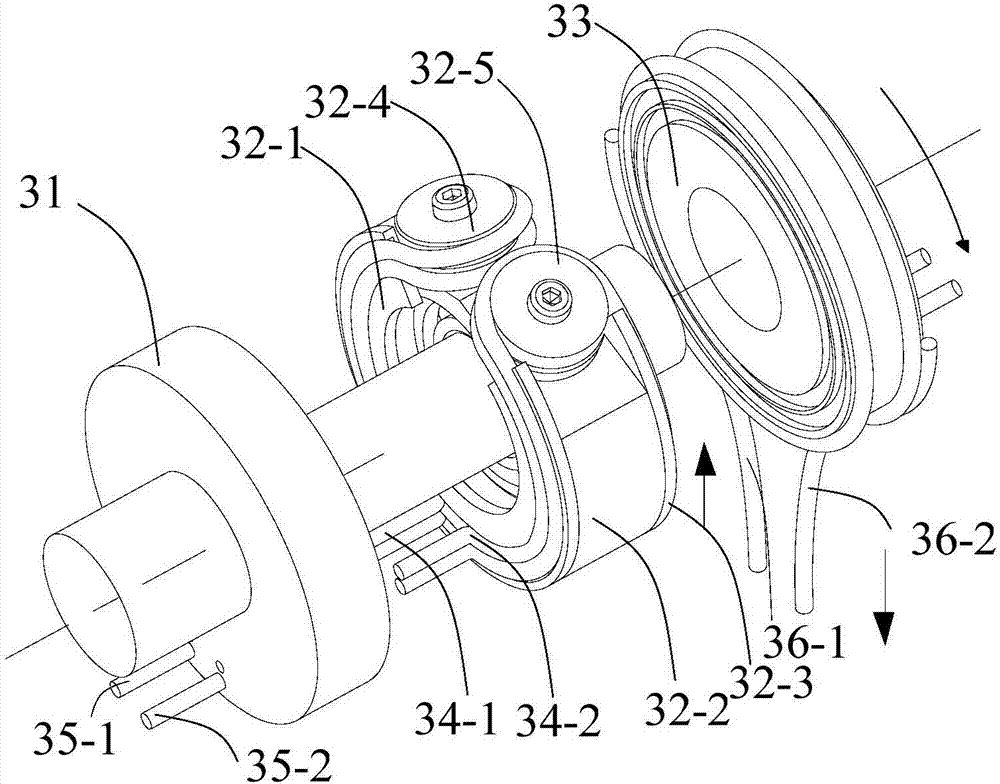

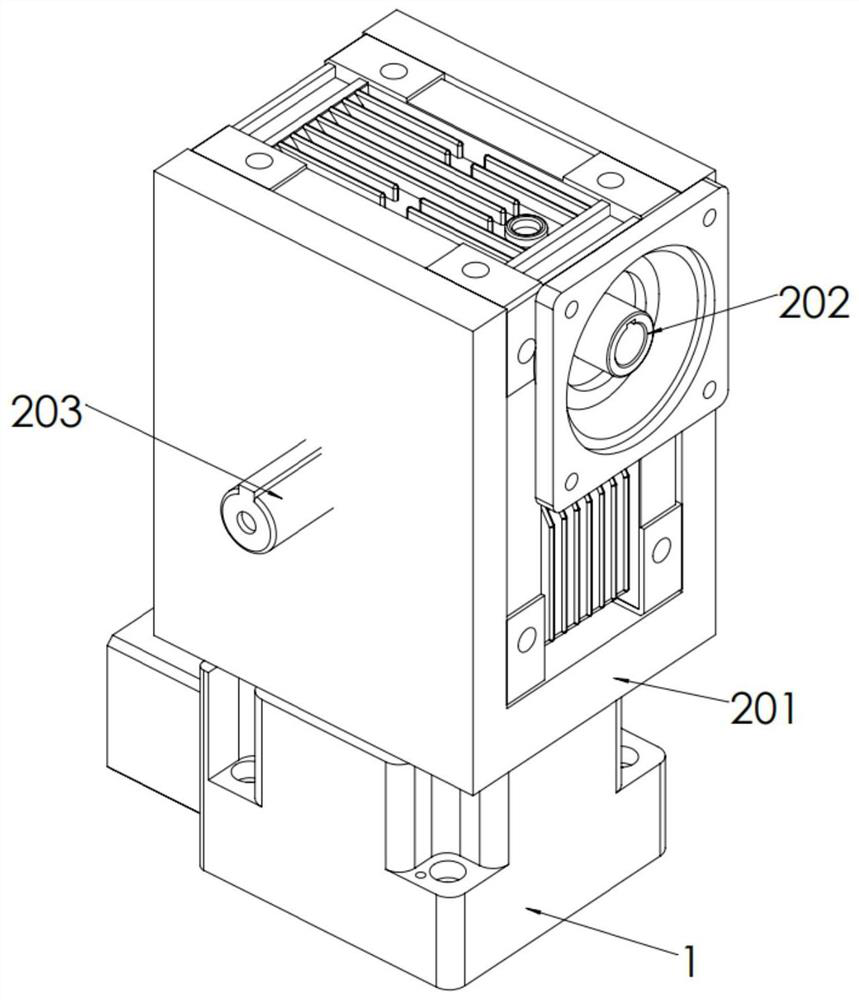

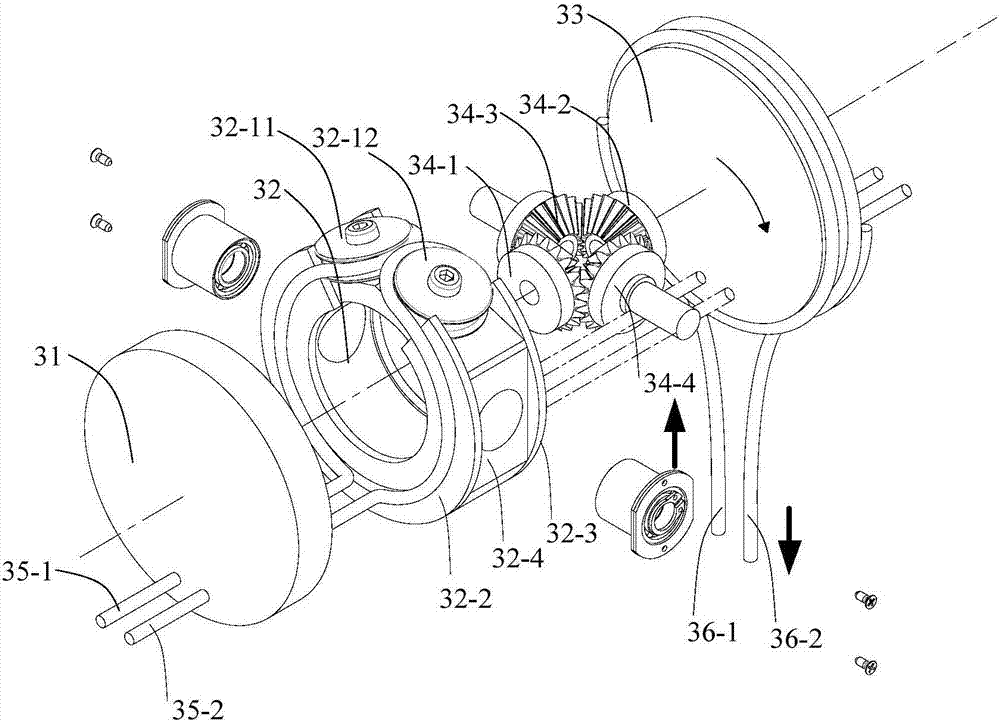

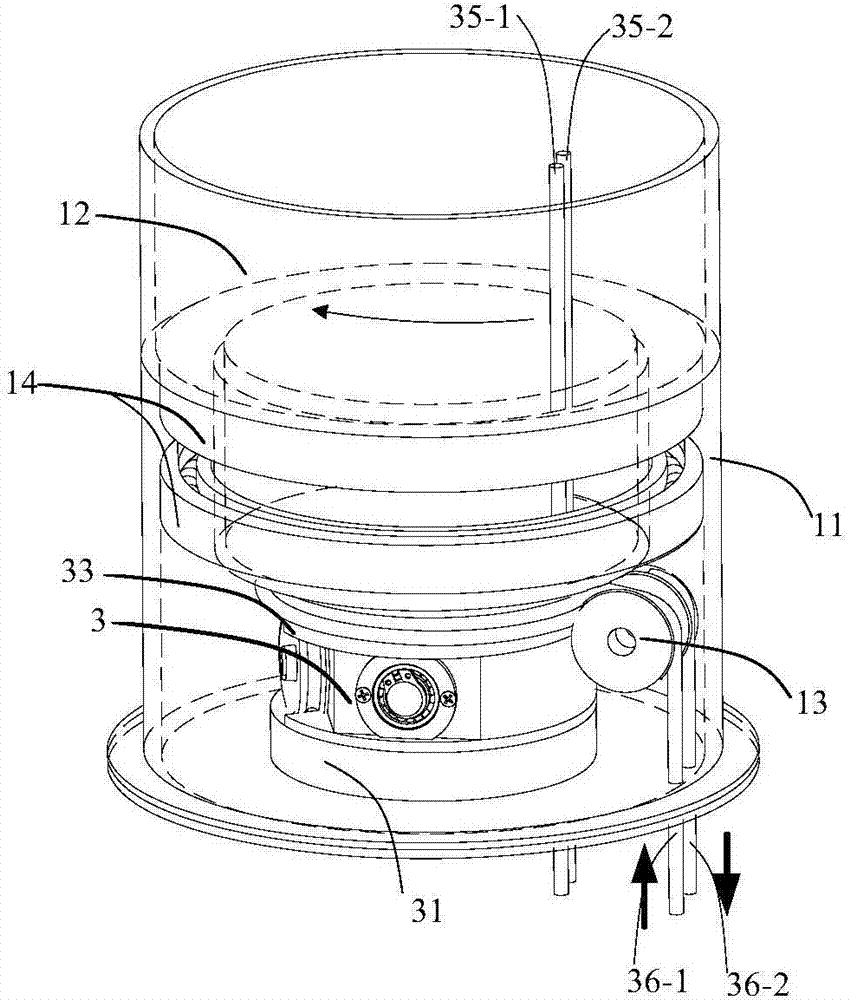

Modular rope-driven decoupling mechanical arm joint and working method thereof

ActiveCN105798899AHigh self-weight ratioImprove drive response characteristicsProgramme-controlled manipulatorJointsMoment of inertiaEngineering

The invention discloses a modular rope-driven decoupling mechanical arm joint and a working method thereof and relates to the field of robots. According to the decoupling mechanism, two different types of modular rope-driven joints are designed, so the problem of motion coupling among all joints of a rope-driven mechanical arm provided with a plurality of joints connected in series is solved. According to the demands of a target task, the rotation type of each joint is changed, and the quantity of the joints of the mechanical aim is increased or reduced, so that assembly of the mechanical arm of a plurality of types of construction can be realized; the application mode and the application range are wide, and the implementation cost is low. A mechanical arm driving unit is arranged at a base, and a rope is used for remote driving, so the rotational inertia of each joint is reduced and the response characteristics of driving are improved. In addition, the interaction safety of the mechanical arm and the environment can be greatly improved due to the flexibility of the rope. The rope-driven modular joint disclosed by the invention is compact in structure, low in rotational inertia, quick in driving response, good in joint flexibility and good in interaction safety.

Owner:南京若希自动化科技有限公司

Drive control integration intelligent integrated joint

The invention discloses a driving and control integrated type intelligent integration joint, which comprises a joint output member, a harmonic speed reducer, a bearing seat, a joint outer casing, a motor body, a brake mechanism, a motor encoder, an integrated circuit module and a joint encoder. The driving and control integrated type intelligent integration joint has the advantages that the integration degree is high, the motor, the driver, the speed reducer and the sensor module needed by a robot joint part are integrated into the joint, and the size of the robot joint part is more compact at the premise of no overheat of the integration joint; an acceleration sensor is integrated into the integration joint, so the external impact force on the integration joint can be detected, and the advanced technique cannot be realized by the traditional industrial robot; an accurate current detector is integrated into the integration joint, and a controller algorithm is matched to realize the intelligent teaching demonstration function, and improve the human-machine interaction function.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

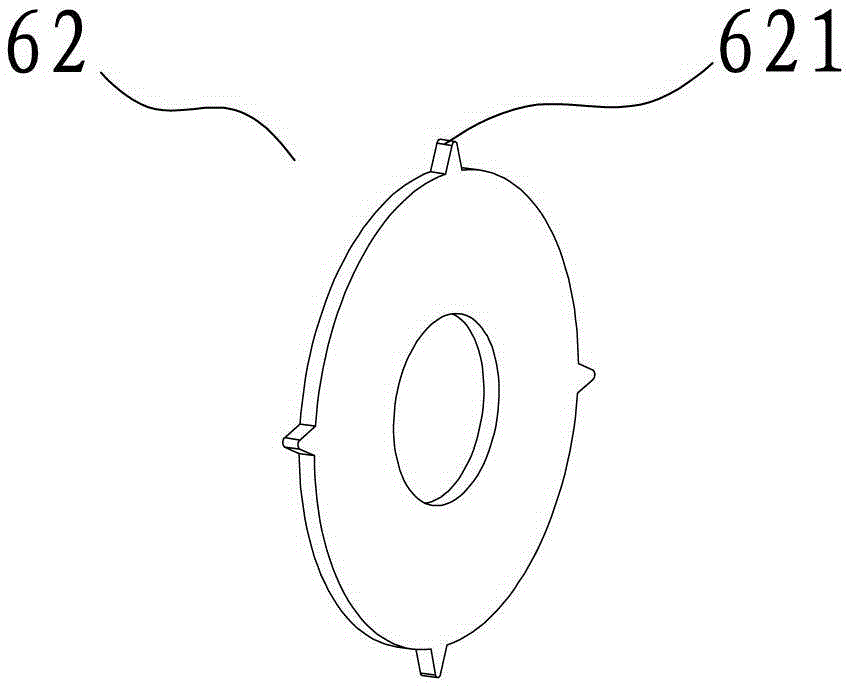

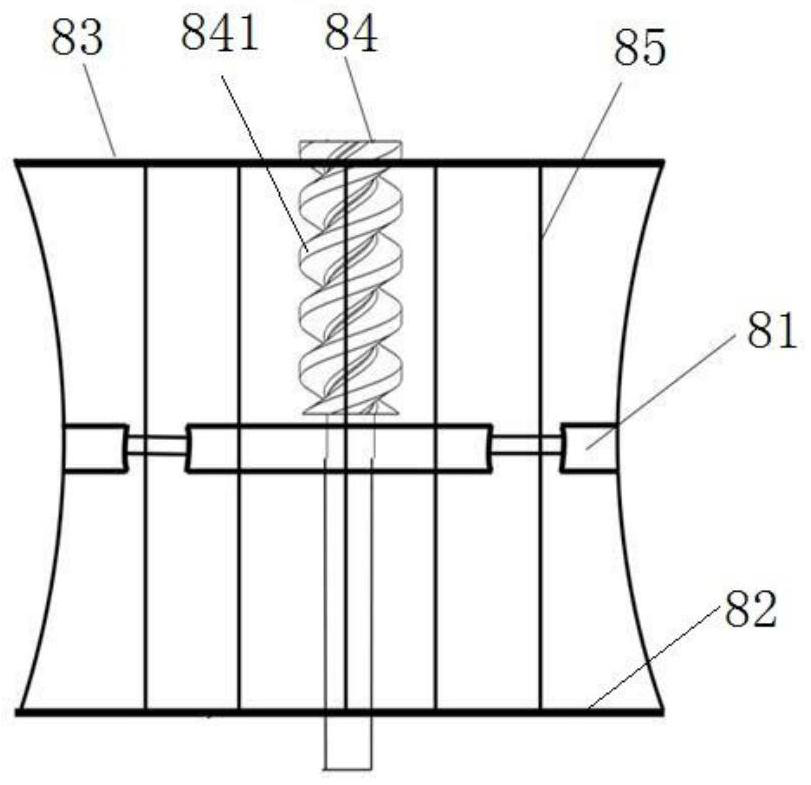

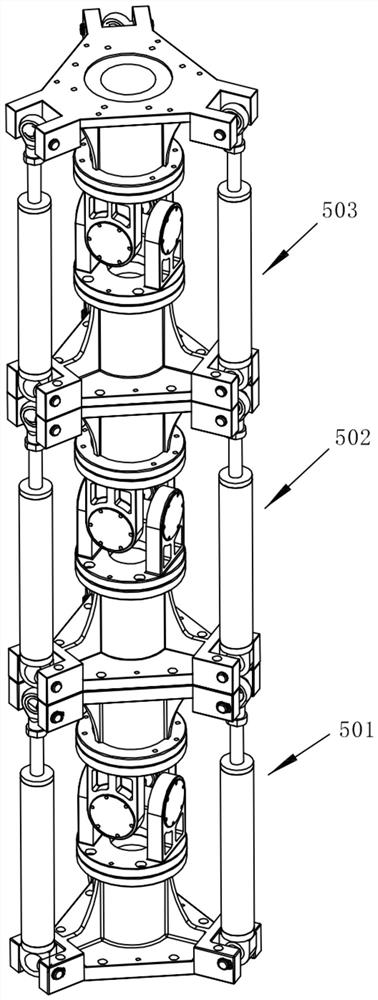

Under-actuated continuum mechanical arm

The invention relates to an under-actuated continuum mechanical arm which comprises three driving motors, three driving ropes and a plurality of joints connected in sequence. Each joint comprises a movable platform and a static platform; the movable platform in each joint is connected with three driven ropes; each joint is connected with three variable-diameter driving mechanisms, the driven ropes in each joint are in one-to-one correspondence with the variable-diameter driving mechanisms, and each driven rope in each joint is connected with the output end of the corresponding variable-diameter driving mechanism; the variable-diameter driving mechanism comprises a variable-diameter pulley, and the variable-diameter pulley comprises a variable-diameter outer ring body; and the outer ring body of the variable-diameter pulley in the variable-diameter driving mechanism at each joint is driven by a corresponding driving rope to rotate. The mechanical arm is simple in structure and small in overall weight and size, and meanwhile the flexibility and the load capacity of the mechanical arm can be effectively guaranteed.

Owner:SUZHOU UNIV

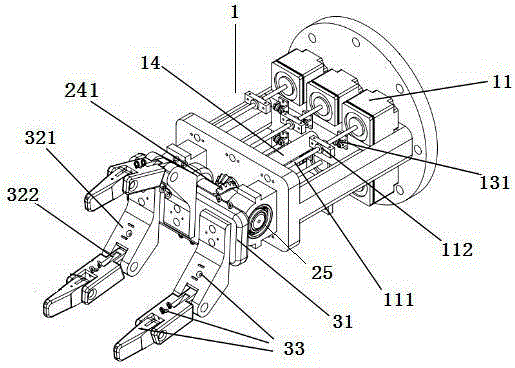

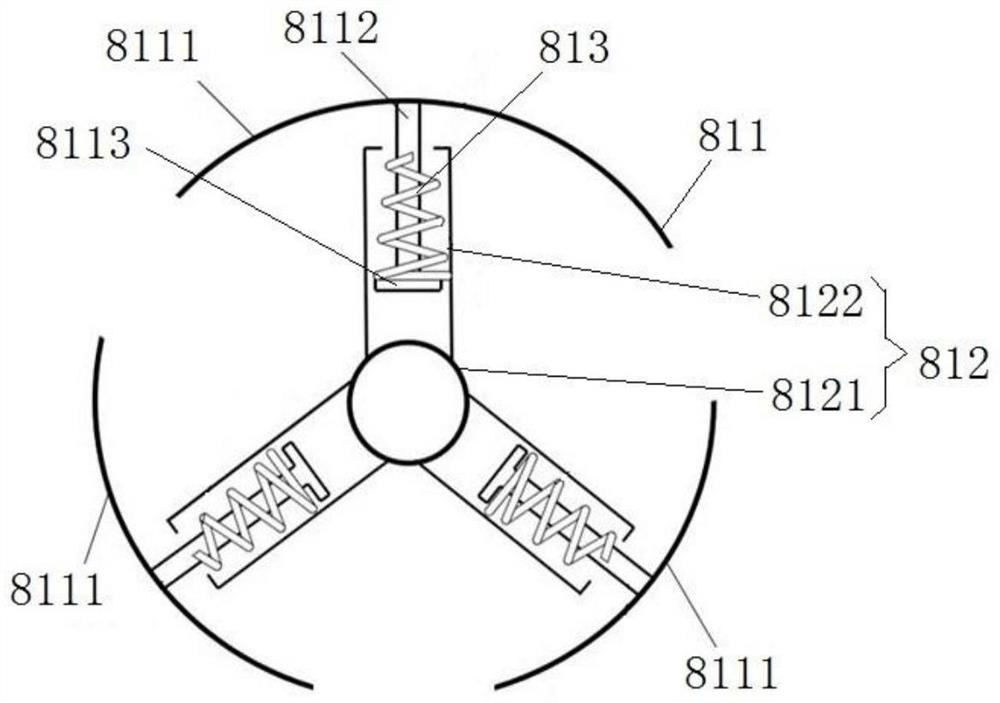

A double-thread underactuated multi-fingered robot end effector driven by a single motor and method thereof

Provided are a single-motor driven double-thread under-actuated multi-fingered robot end effector and method. The single-motor driven double-thread under-actuated multi-fingered robot end effector comprises at least two robot fingers, a finger grabbing range adjusting device and a finger grabbing and opening device; and the finger grabbing range adjusting device controls the robot fingers to transversely move to adjust the grabbing range of the robot fingers, and the finger grabbing and opening device controls the robot fingers to longitudinally move so that the robot fingers can grab tightly or be opened.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Compact transmission structure of adjacent joints and mechanical arm

PendingCN114851244AMiniaturizationAchieve lightweightProgramme-controlled manipulatorJointsElectric machineryMechanical joint

The invention belongs to the technical field of mechanical joint transmission, and discloses a compact transmission structure of adjacent joints, which is characterized in that a fixed end of a power source sleeves the outer side of a hollow shaft; the first end cover sleeves the outer side of the hollow shaft; the inner ring is in sliding connection with the outer ring through a roller; the inner side of the opening end is connected with the rotating end of the power source through a flexible bearing, and the outer side of the opening end is meshed with the inner ring. The bottom end is pressed between the first end cover and the outer ring; the power source is located on the inner side of the flexible gear. The flexible gear is positioned on the inner sides of the outer ring and the inner ring; the end, close to the bottom end, of the hollow shaft is sleeved with an output end code disc, and the end, close to the opening end, of the hollow shaft is sleeved with a motor end code disc. The problem that an existing integrated joint is long in overall length can be effectively solved, miniaturization and light weight of a robot are achieved, stronger power output is obtained on the basis of miniaturization and light weight, and therefore the larger load-weight ratio is obtained. The invention further discloses a mechanical arm with the transmission structure.

Owner:SICHUAN FUDE ROBOT

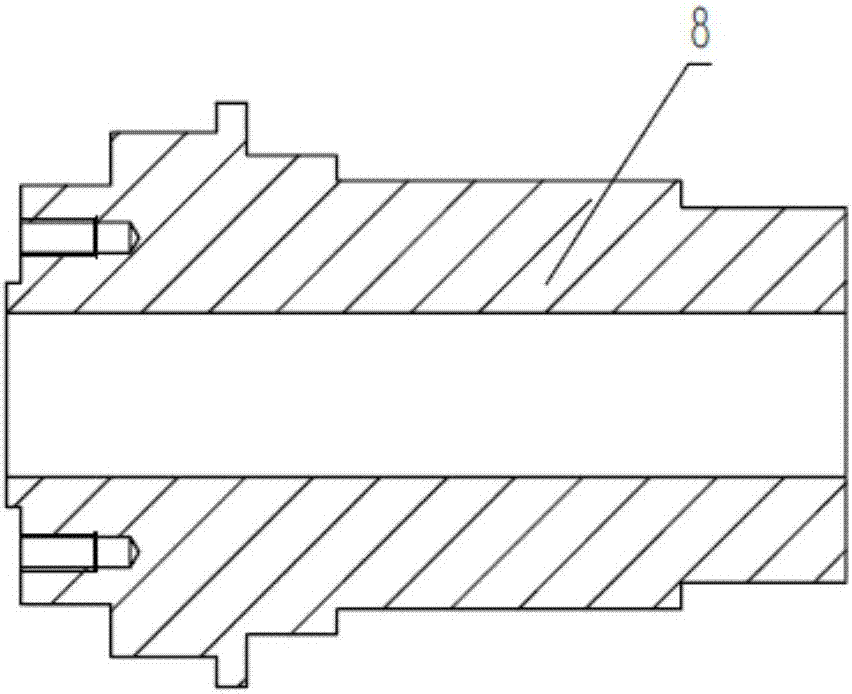

A mechanical lock device for connection and positioning

ActiveCN110360202BSimple structureEasy and reliable dockingFastening meansProduction lineElectric machinery

The invention discloses a mechanical locking device for connecting and positioning, and belongs to a locking and positioning device. The mechanical locking device aims to solve the problem that when two mechanisms or equipment are connected, the structure is complex due to the fact that a plurality of execution mechanisms and detection elements need to be adopted. The mechanical locking device comprises a motor, nuts, a screw sleeve, a guide positioning cylinder, torsion springs, a transmission device, a base and a plurality of spring bolts; and the motor and the guide positioning cylinder arecorrespondingly fixed to the base, the screw sleeve is arranged on the outer side of the guide positioning cylinder in a sliding and sleeving mode, the nuts are rotationally arranged on the base through the transmission device and are in threaded fit with the screw sleeve, the motor drives the nuts to rotate through the transmission device, each spring bolt is hinged to the screw sleeve through the corresponding torsion spring, the plurality of spring bolts are uniformly distributed on the circumference of the screw sleeve, and the plurality of spring bolts can extend into the interior of theguide positioning cylinder. The mechanical locking device is suitable for positioning and transferring of trays and the like of the automatic production line.

Owner:HARBIN INST OF TECH

Modular Rope-Driven Decoupled Robotic Arm Joint and Its Working Method

ActiveCN105798899BHigh self-weight ratioImprove drive response characteristicsProgramme-controlled manipulatorJointsModularityEngineering

Owner:南京若希自动化科技有限公司

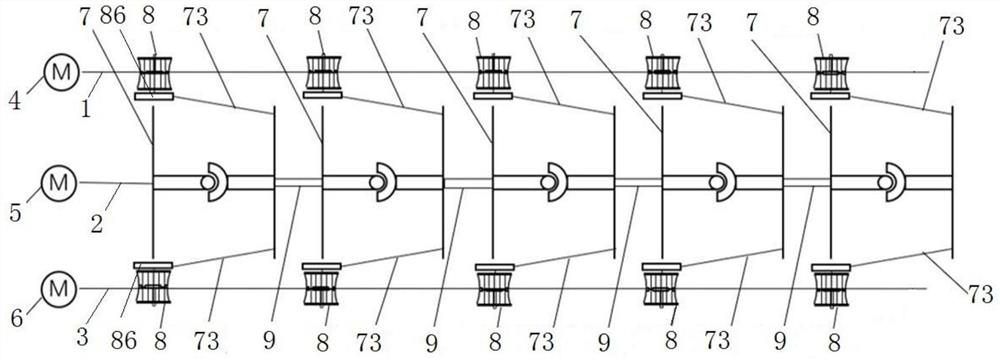

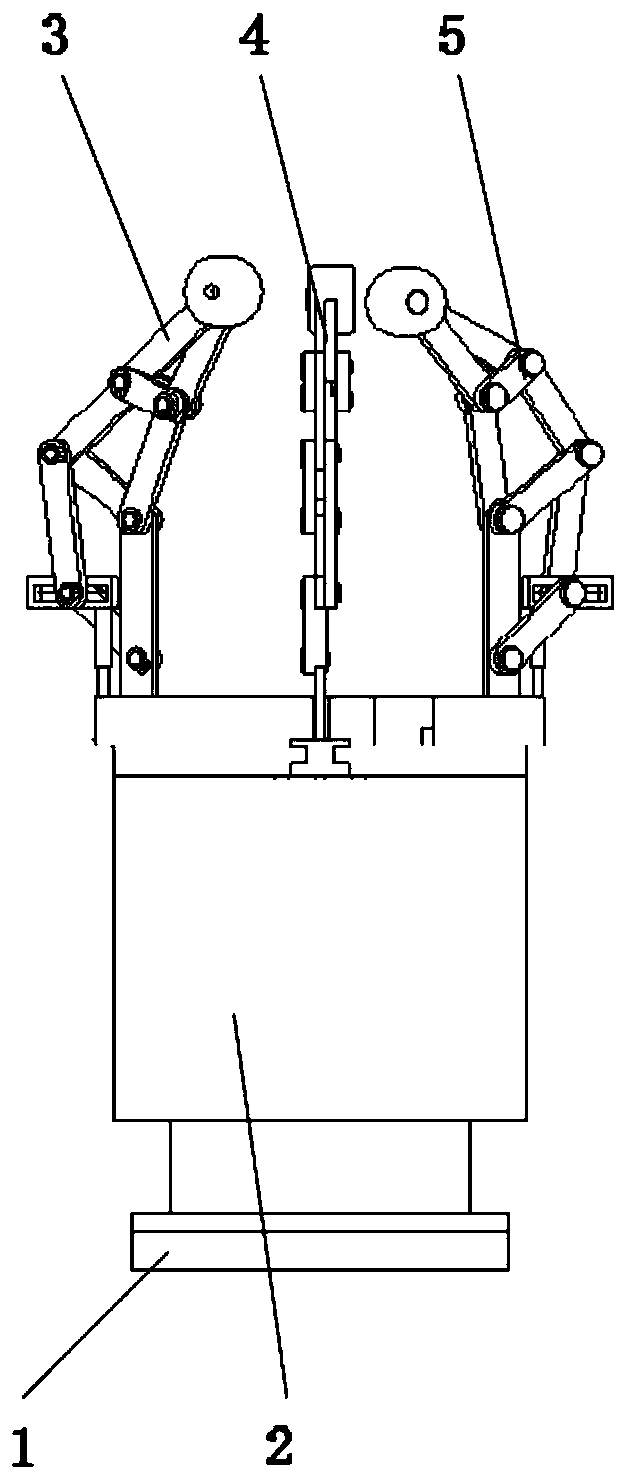

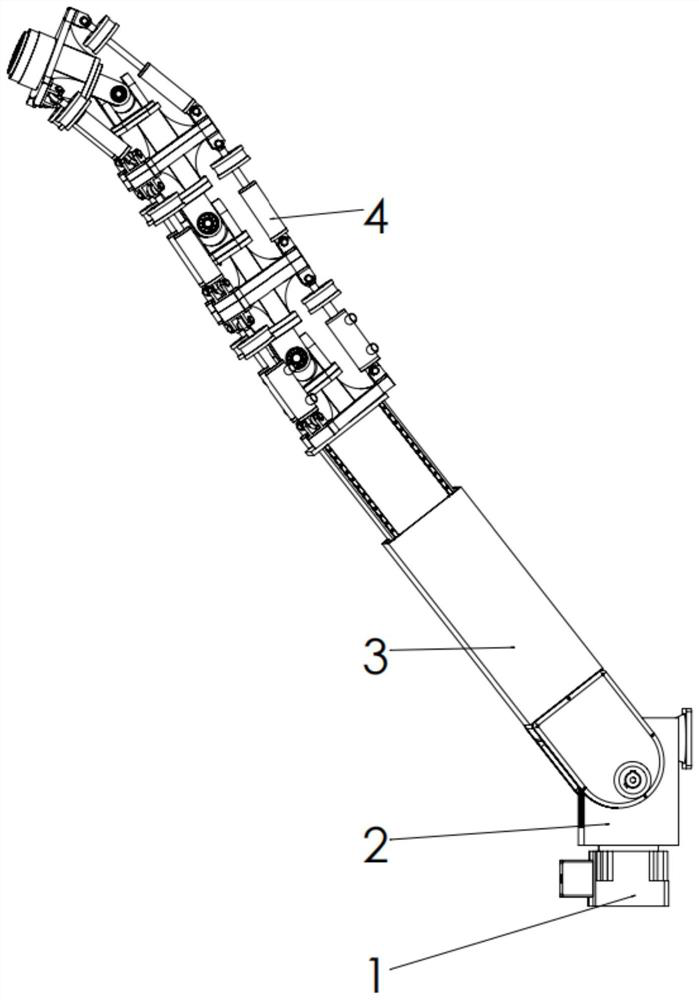

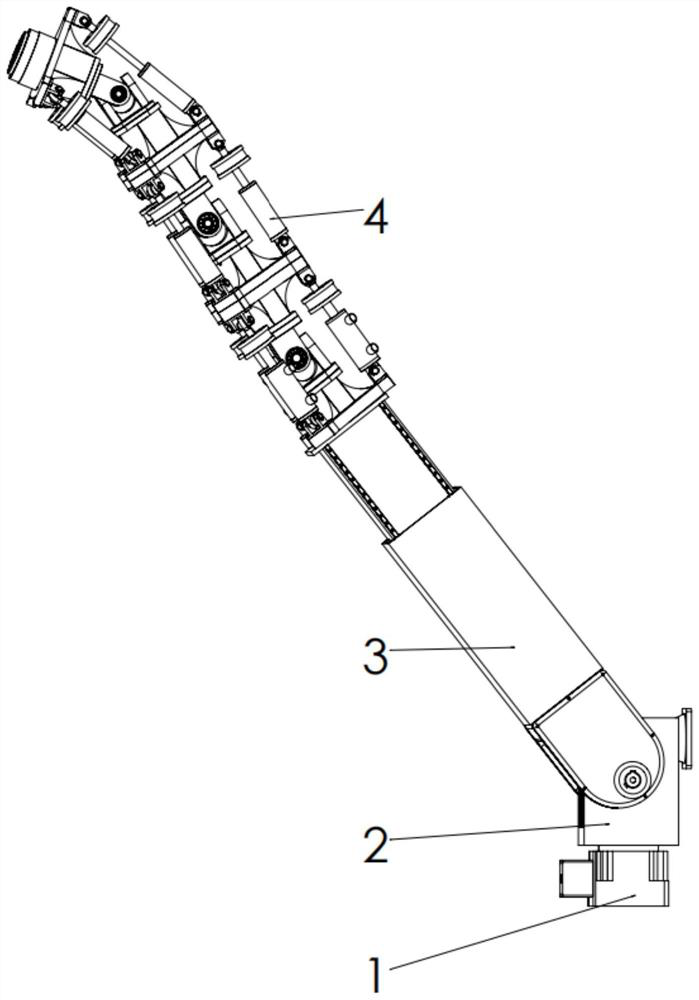

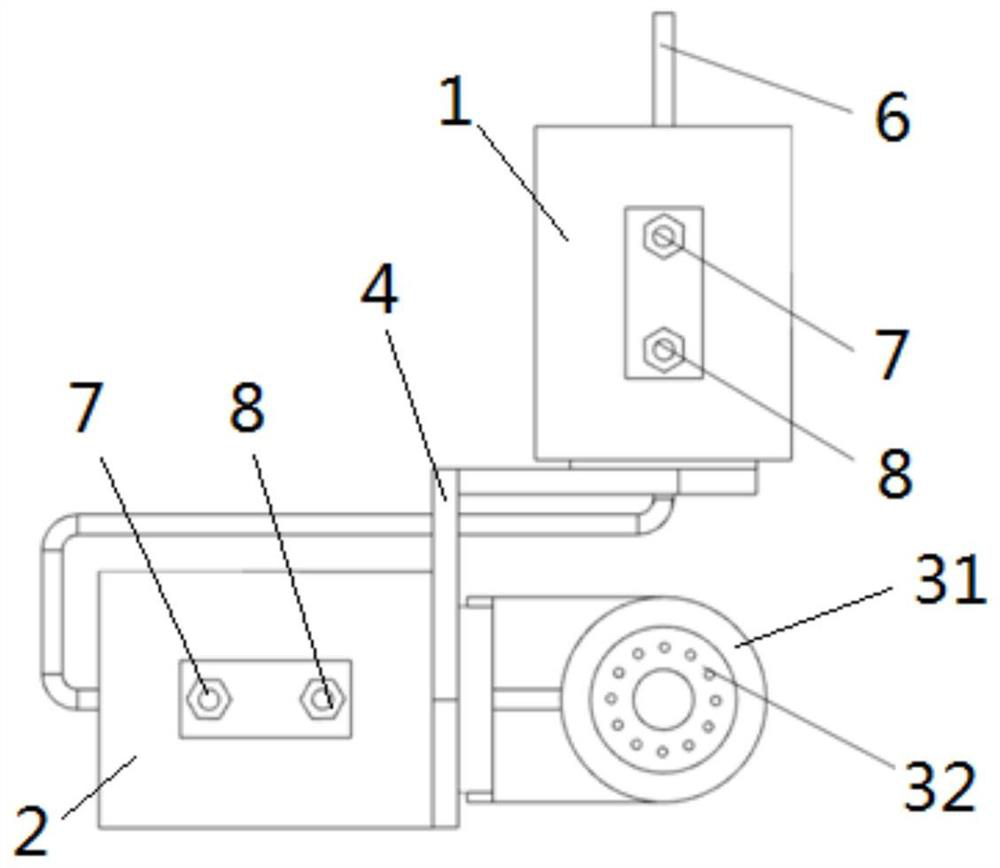

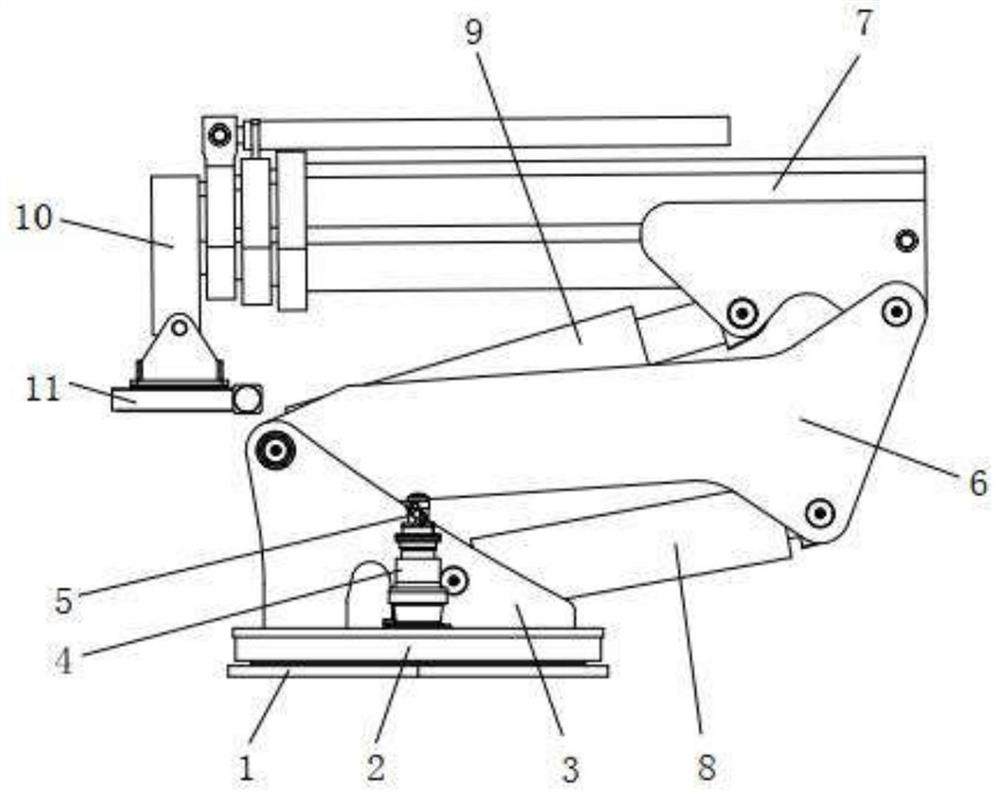

Building robot and high-load-dead-weight-ratio mechanical arm assembly thereof

The invention discloses a high-load-dead-weight-ratio mechanical arm assembly. The high-load-dead-weight-ratio mechanical arm assembly comprises a hydraulic arm assembly provided with a plurality of joint assemblies connected in sequence, each joint assembly comprises a main base, a first hydraulic assembly, an auxiliary base and a universal coupling, the main bases and the auxiliary bases are connected through the universal couplings between the main bases and the auxiliary bases, main mounting parts are arranged on the main bases, auxiliary installation parts are arranged on the auxiliary bases, the two ends of the first hydraulic assemblies are correspondingly connected with the main mounting parts and the auxiliary mounting parts, and the two main mounting parts are not symmetrical about the orthographic projection of any shaft of the universal couplings. The invention further discloses the building robot. The positions of the hydraulic assemblies beside the universal couplings are reasonably arranged, so that the mechanical arm assembly can take and place materials at any angle and any position within the working length, the load-weight ratio of a mechanical arm can be remarkably increased, the flexibility and positioning precision of the robot are improved, the high-load-dead-weight-ratio mechanical arm assembly can be suitable for various indoor and outdoor complex ground working environments, and the cost of a robot moving body is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

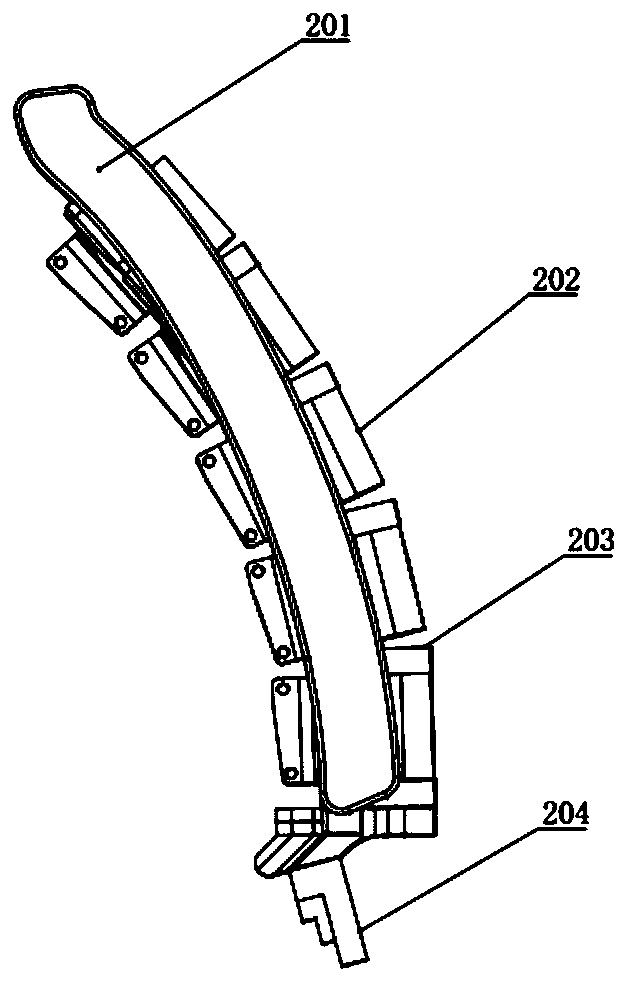

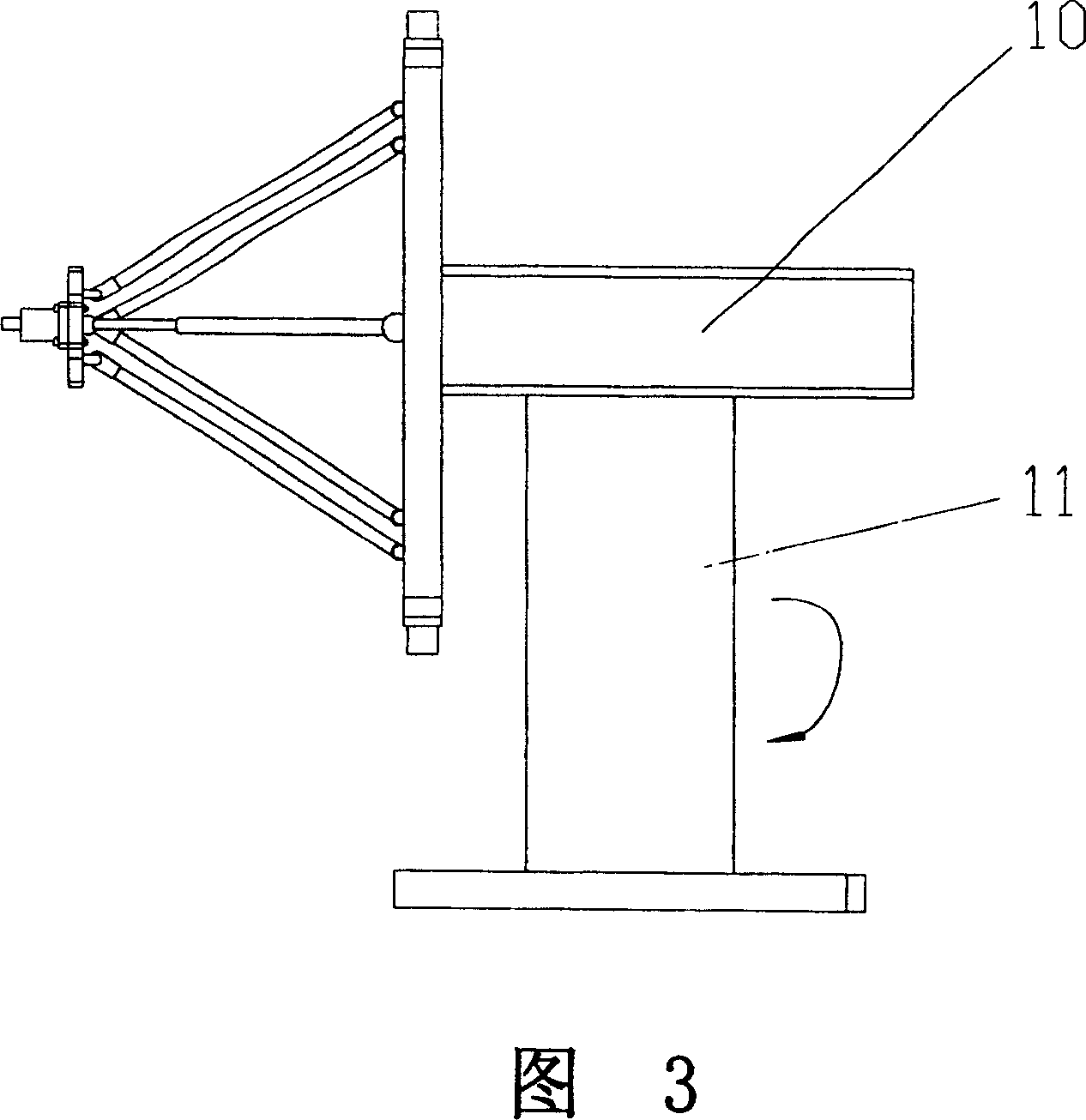

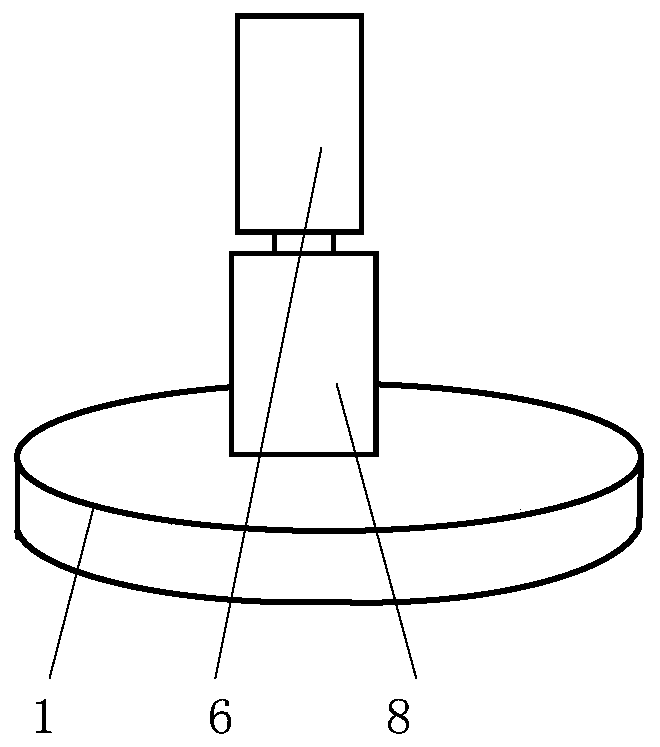

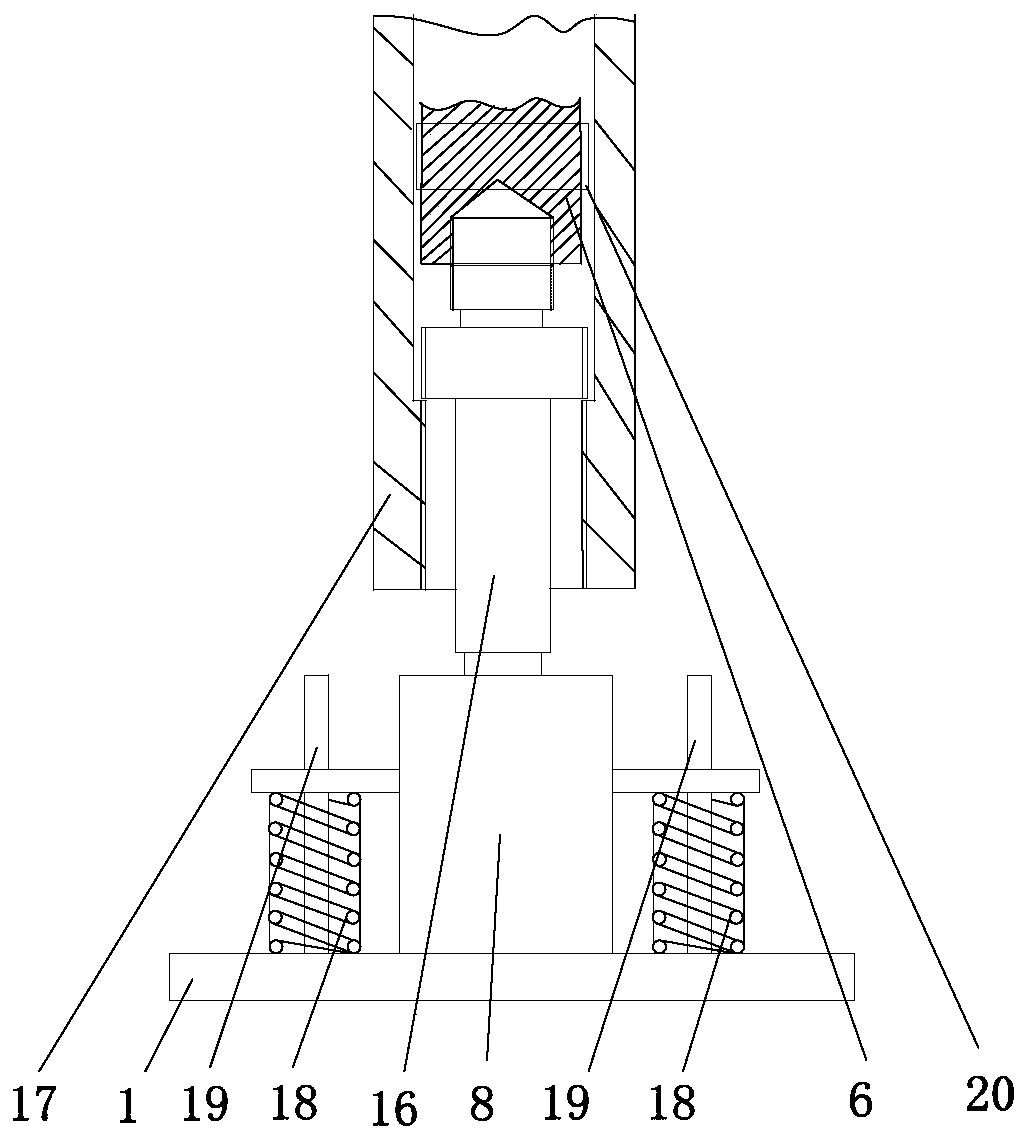

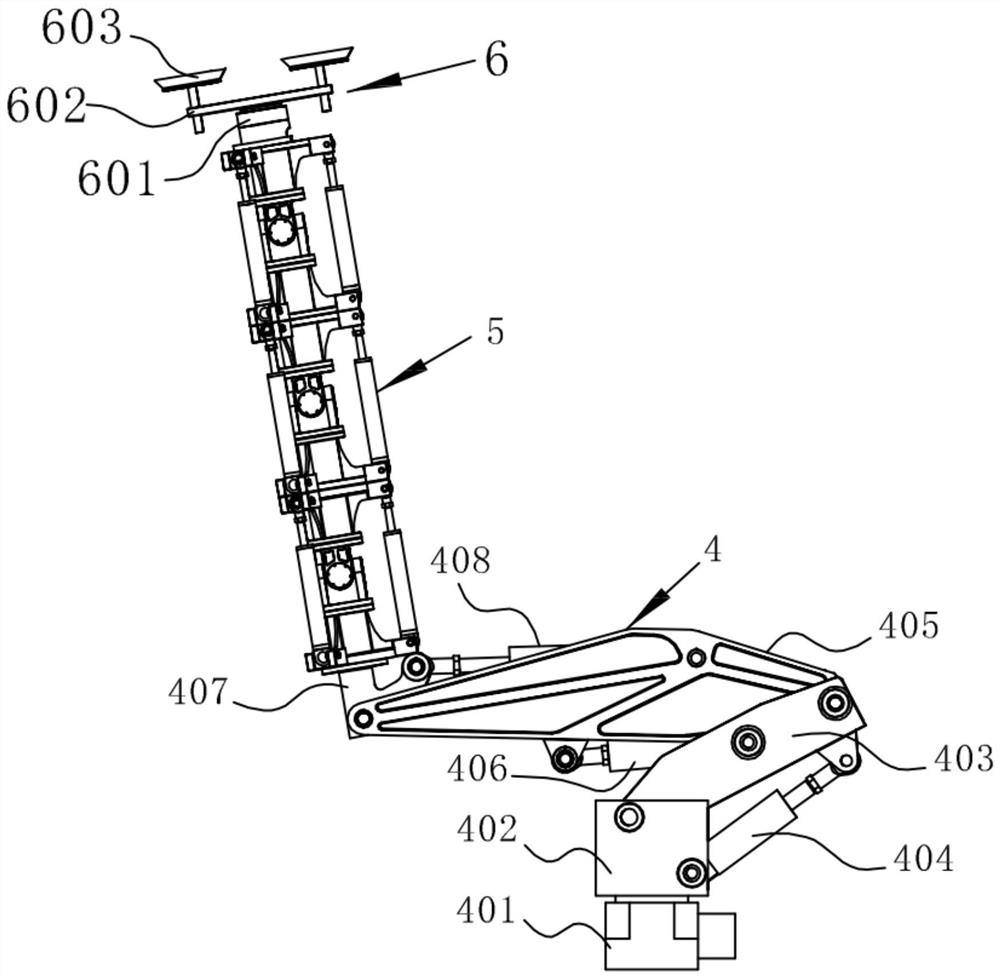

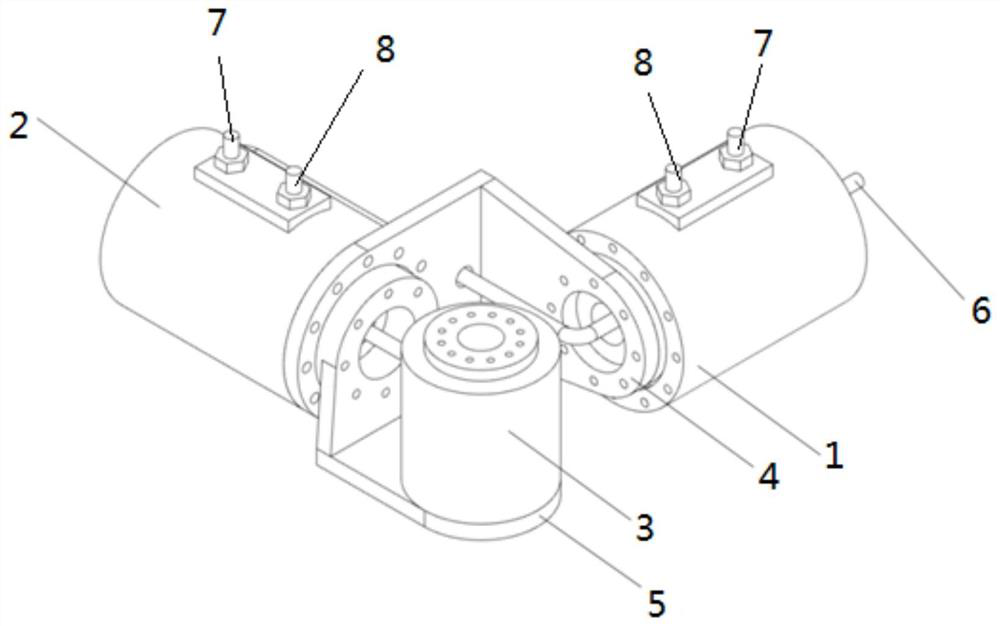

A hydraulic lightweight parallel manipulator

ActiveCN112621720BLight structureRealize stepless speed regulationProgramme-controlled manipulatorControl engineeringParallel manipulator

A hydraulic lightweight parallel mechanical arm belongs to the field of robot structure technology and is composed of a mobile platform connection component, a large arm mobile component, a mechanical large arm component and a hydraulic parallel mechanical small arm component. The large arm mobile component is installed on the mobile platform On the connection assembly, the mechanical boom assembly is installed on the boom moving assembly, and the hydraulic parallel mechanical small arm components are installed on the mechanical boom assembly. Compared with other existing methods, the advantages of the present invention are: using hydraulic components to assemble the small arm of the manipulator, which is lighter in structure, can realize stepless speed regulation during the movement of the manipulator, and has higher motion precision; adopts hydraulic parallel Combined assembly in a combined way to realize the six degrees of freedom of the robotic arm, compared with other existing robotic arms, it is lighter in weight and has a higher load-to-weight ratio; the assembled combined robotic arm can meet the requirements of various types of work, The flexible transformation of various terminal execution parts can be realized by using the replaceable execution terminal installation parts.

Owner:SHENZHEN INST OF ADVANCED TECH

Hydraulic lightweight parallel mechanical arm

ActiveCN112621720ALight structureRealize stepless speed regulationProgramme-controlled manipulatorRobot handEngineering

A hydraulic lightweight parallel mechanical arm belongs to the technical field of robot structures and comprises a moving platform connecting assembly, a big arm moving assembly, a mechanical big arm assembly and a hydraulic parallel mechanical forearm part, the big arm moving assembly is mounted on the moving platform connecting assembly, the mechanical big arm assembly is mounted on the big arm moving assembly, and the hydraulic parallel mechanical forearm part is mounted on the mechanical big arm assembly. Compared with other existing methods, the method has the beneficial effects that a mechanical arm forearm is assembled through a hydraulic assembly, the structure is lighter and more convenient, stepless speed regulation of the mechanical arm in the movement process can be achieved, and the movement precision is higher; the six-degree-of-freedom mechanical forearm is combined and assembled in a hydraulic parallel connection mode, six degrees of freedom of the mechanical forearm are achieved, and compared with other existing mechanical arms, the six-degree-of-freedom mechanical forearm is lighter and has a higher load self-weight ratio; and the assembly type combined mechanical arm is adopted, the requirements of various types of work can be met, and flexible conversion of various terminal execution components can be achieved through a replaceable execution terminal installation part.

Owner:SHENZHEN INST OF ADVANCED TECH

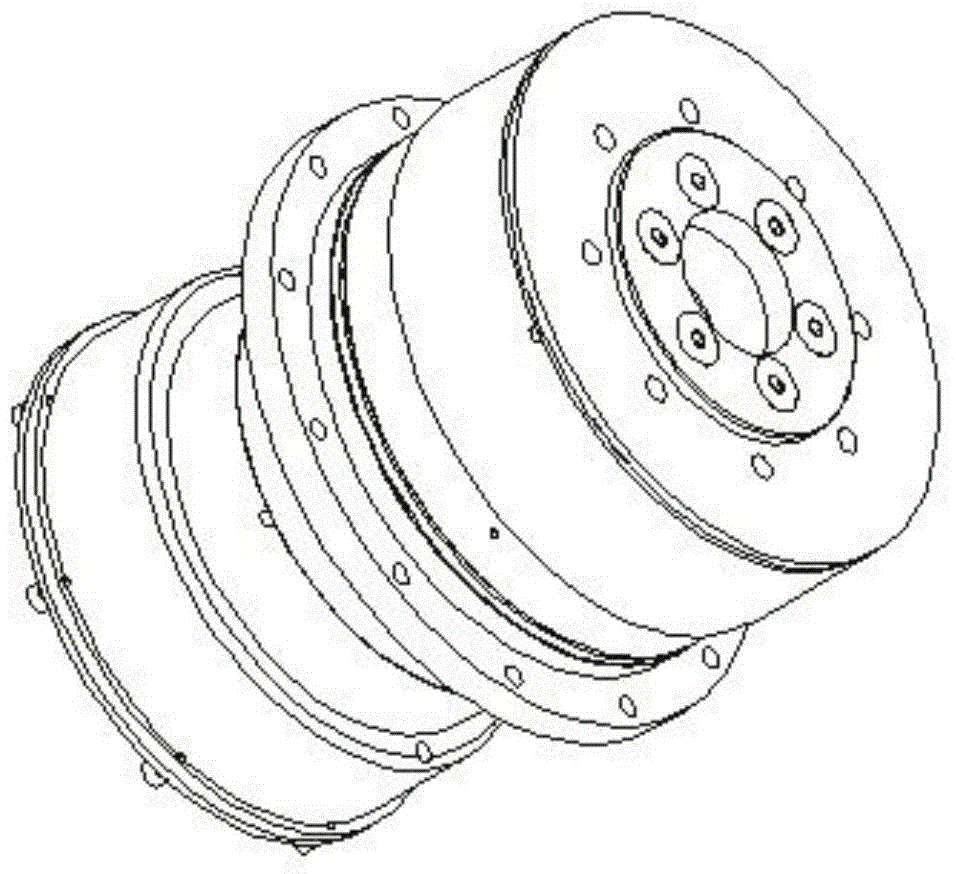

Hip joint for foot type robot and foot type robot

ActiveCN113511282AReduce weightMeet the needs of useVehiclesPhysical medicine and rehabilitationReduction drive

The invention provides a hip joint for a foot type robot and the foot type robot. The hip joint for the foot type robot comprises a first hydraulic rotary cylinder with a first shell and a first output end; a second hydraulic rotary cylinder with a second shell and a second output end; a servo motor which comprises a shell and a rotor; a first connecting frame which is provided with a first shell connecting part and a first output connecting part; and a second connecting frame which is provided with a second shell connecting part and a second output connecting part. According to the hip joint for the foot type robot jointly driven by hydraulic pressure and electric power, in roll rotation and pitch rotation, the hip joint adopts the hydraulic rotary cylinders to replace a traditional driving mode that a motor is matched with a speed reducer, the hydraulic rotary cylinder driven by hydraulic pressure can provide large torque, and therefore the use requirement of the hip joint is met; for yaw rotation, as the action range is small and the load weight is small, a rotary motor can meet the use requirement, and the overall weight of the robot is reduced.

Owner:THE 21TH RES INST OF CHINA ELECTRONIC TECH GRP CORP

Reconfigurable rope-actuated series decoupled robotic arm joint and its working method

ActiveCN105798947BHigh self-weight ratioImprove drive response characteristicsJointsKinematic couplingModularity

The invention discloses a reconfigurable rope-driven tandem decoupling mechanical arm joint and a working method thereof, and solves the kinematic coupling problem of joints of a multi-joint tandem rope-driven mechanical arm. The reconfigurable rope-driven tandem decoupling mechanical arm joint has the characteristics that based on a decoupling mechanism, modularized rope-driven joints of two different types are designed; the rotation types of the joints are changed and the number of mechanical arm joints is increased and decreased according to the requirement of a target task, so that the assembly of mechanical arms with various structures is achieved; the application manner is wide in application range, and the cost is low; a mechanical arm driving unit is positioned at a base, the rope remote driving is adopted, and the rotational inertia of the joints is reduced, so that the driving response characteristic is improved; besides, the flexibility of the ropes greatly improve the safety of interaction of the mechanical arm and the environment; and a rope-driven modularized joint is compact in structure, low in rotational inertia, quick in driving response, and good in flexibility and security interaction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mechanical claw differential rotation opening and closing mechanism for underwater robot

The invention discloses a mechanical claw differential rotation opening and closing mechanism for an underwater robot. The mechanical claw differential rotating opening and closing mechanism comprises a main shell and a differential gear box installed under the main shell, a main rotating shaft and an auxiliary rotating shaft are arranged in the main shell, the main rotating shaft is of a hollow structure in the axial direction, the auxiliary rotating shaft penetrates through the center of the main rotating shaft, and the two ends of the auxiliary rotating shaft penetrate out of the driving shaft. The upper end of the auxiliary rotating shaft is connected with an auxiliary transmission gear meshed with a first expansion gear, and the lower end of theauxiliary rotating shaft is connected with a first bevel gear; the upper end of the main rotating shaft is connected with a main rotating gear which is meshed with a second expansion gear, and the lower end is connected with a second bevel gear; and a third bevel gear and a fourth bevel gear which are meshed with the first bevel gear and the second bevel gear are arranged between two sides of the first bevel gear and the second bevel gear and are connected with an output shaft. Opening, closing and rotation of the tail end can be controlled at the same time in the same sealing section, and higher flexibility and load dead weight ratio are achieved.

Owner:南京云智控产业技术研究院有限公司

Ontract replaceable joint of large space service robot

The invention relates to an ontract replaceable joint of a large space service robot, in particular to a robot joint, which aims to solve the problems of poor joint control accuracy, large joint mass caused by using planetary gear transmission, small load self-weight ratio for a robot, and poor integration caused by arranging a control circuit outside a joint of the traditional large space service robot. The output end of a transmission shaft for a motor is connected with a pinion in a transmission way; the pinion is engaged with a bull gear; the bull gear is connected with a hollow shaft through a key in a transmission way; the hollow shaft is integrated with a harmonic speed reducer; a cylindrical hollow shell is arranged inside the hollow shaft; the tail of the cylindrical hollow shellis connected with a back cap of the joint; the harmonic speed reducer is connected with the small diameter end of a torque transducer which is arranged inside the output shell of the joint and is sleeved outside the cylindrical hollow shell; and the large diameter end of the torque transducer is connected with the output shell of the joint in a dismountable way. The invention is used for large space service robots.

Owner:HARBIN INST OF TECH

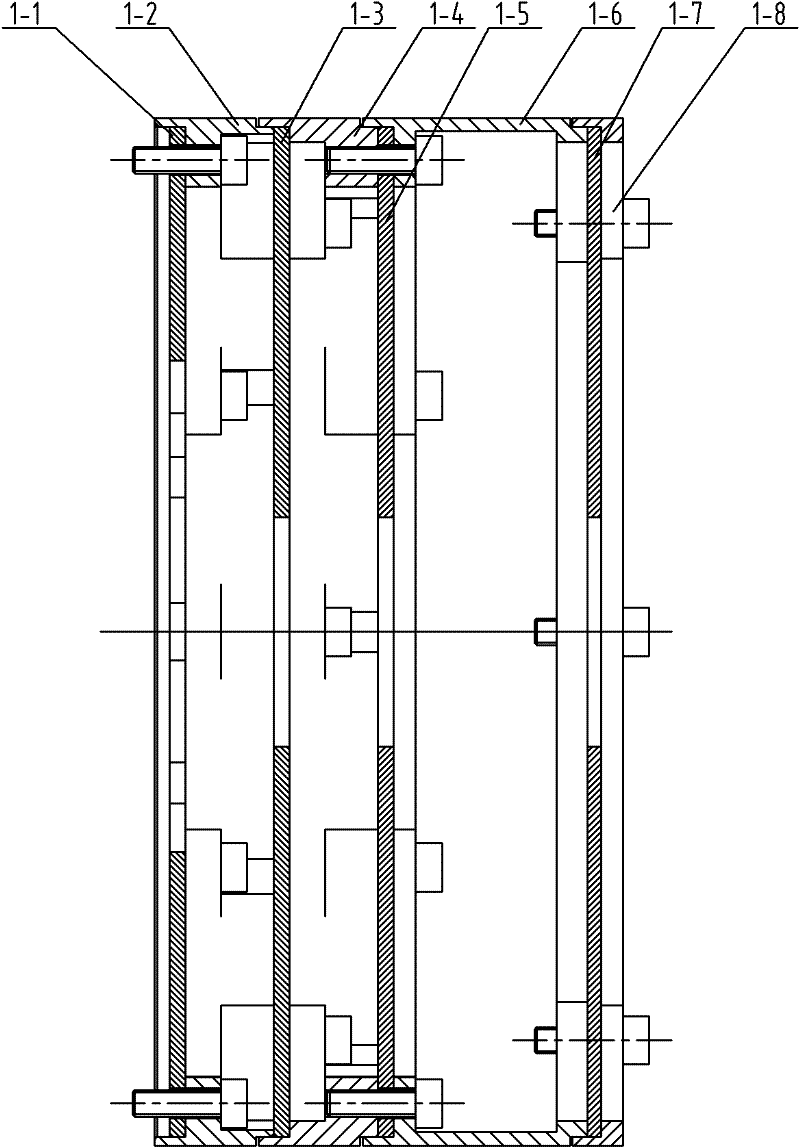

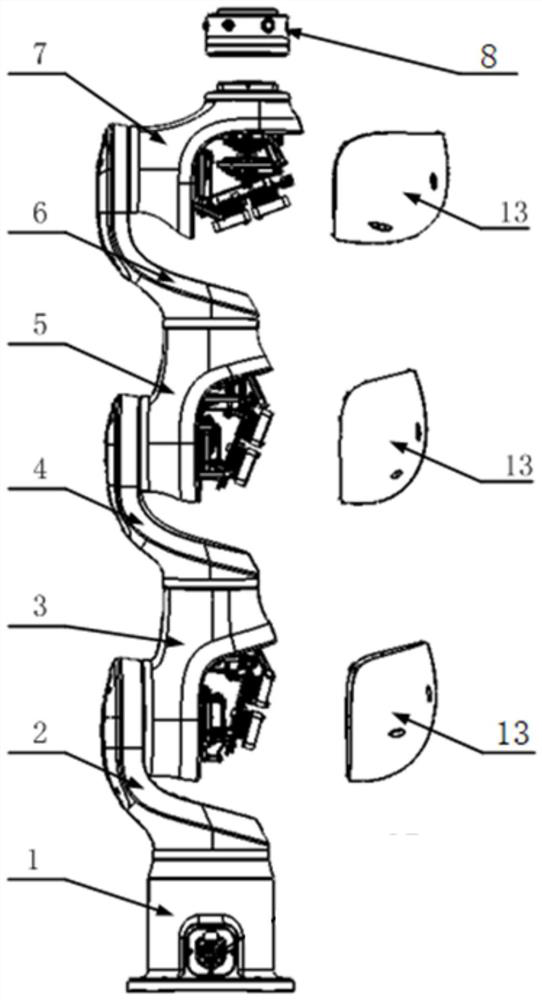

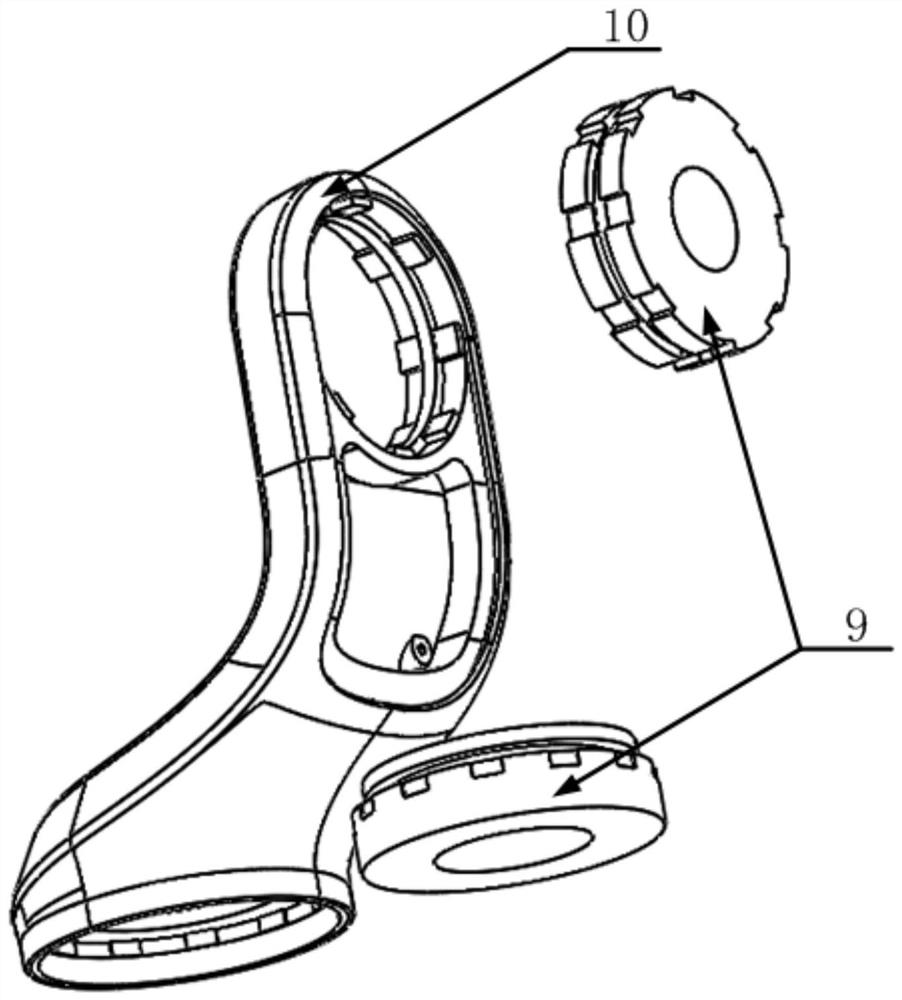

Lightweight mechanical arm and robot with same

ActiveCN109262601BReduce weightHigh self-weight ratioProgramme-controlled manipulatorJointsRobotic armSimulation

The invention discloses a light-weight mechanical arm and a robot having the same. The light-weight mechanical arm includes a base, a first arm body, a second arm body, a third arm body, a fourth arm body, and a fifth arm body , the sixth arm body, the end effector, the first modular joint, the second modular joint, the third modular joint, the fourth modular joint, the fifth modular joint, the sixth modular joint and the seventh modular joint Joints, the base, the second arm, the fourth arm, and the sixth arm all have hollow cavities, the first modular joint is located in the hollow cavity of the base, the second modular joint and the third modular joint are located In the body of the second arm, the fourth modular joint and the fifth modular joint are located in the fourth arm body, and the sixth modular joint and the seventh modular joint are located in the sixth arm body. The overall weight of the robot arm is reduced, and the load-to-weight ratio of the robot arm is improved. The modular joints are self-contained and can be directly disassembled and assembled as a whole.

Owner:SIASUN CO LTD

Folding and telescopic arm combined type robot

InactiveCN114670242AMeet large load requirementsHigh self-weight ratioArmsHydraulic cylinderHydraulic motor

The invention belongs to the field of specialized robots, and particularly relates to a folding and telescopic arm composite robot which comprises a base, a slewing bearing, a base, a speed reducer, a hydraulic motor, a lower swing arm, a telescopic arm, a hydraulic cylinder, a pitching arm and a worm and gear speed reducer. The base is arranged on the base through the slewing bearing, the hydraulic motor drives the base to rotate, and the whole robot achieves rotary motion. A lower swing arm and a telescopic arm of the robot can be folded and telescopic and driven by a hydraulic cylinder, and the working range and posture of the robot can be adjusted. The telescopic arm of the robot is driven by the hydraulic cylinder, the large-load requirement is met, and meanwhile the working range is greatly enlarged. During working, the hydraulic cylinders stretch out, and the robot is unfolded; and when the robot is transported and stored, the hydraulic cylinder retracts, and the robot retracts. The tail end of the robot is connected with a load part through a worm and gear speed reducer, rotating power is transmitted, and the robot has large load and self-locking capacity.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com