A dual-arm robot modular joint with hollow structure

A technology of modular joints and robots, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of non-applicability, high cost, low transmission accuracy, etc., and achieve high load-to-weight ratio, high transmission accuracy, and high integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

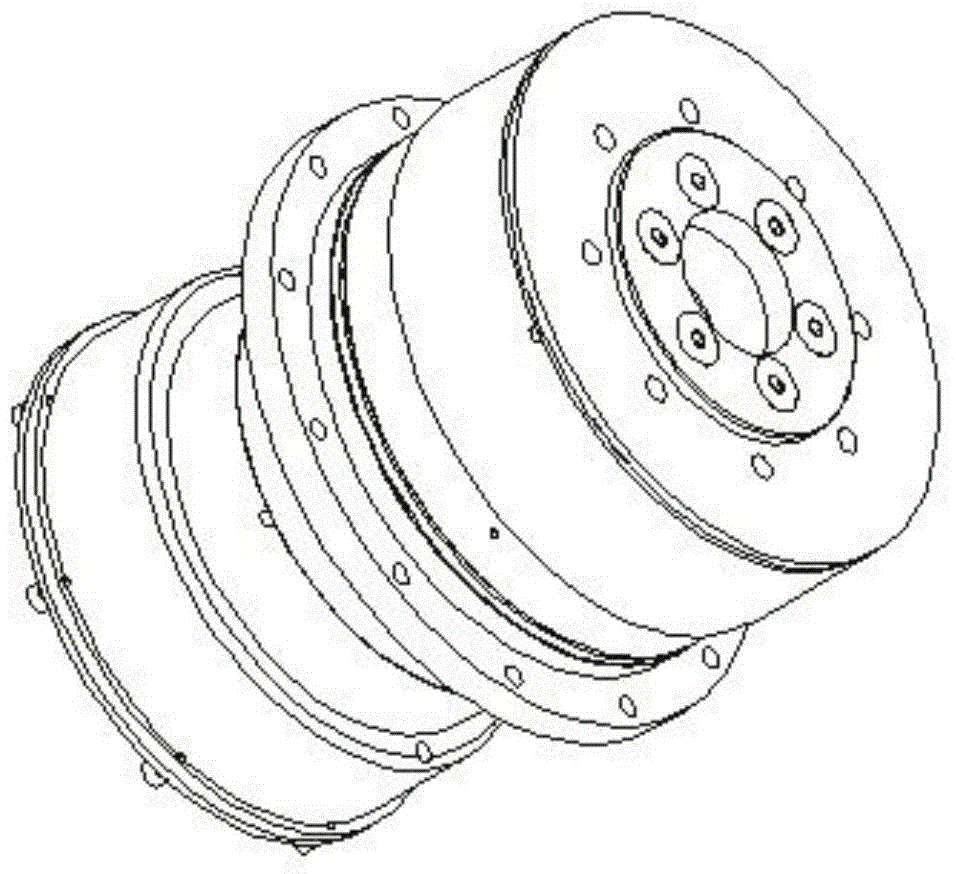

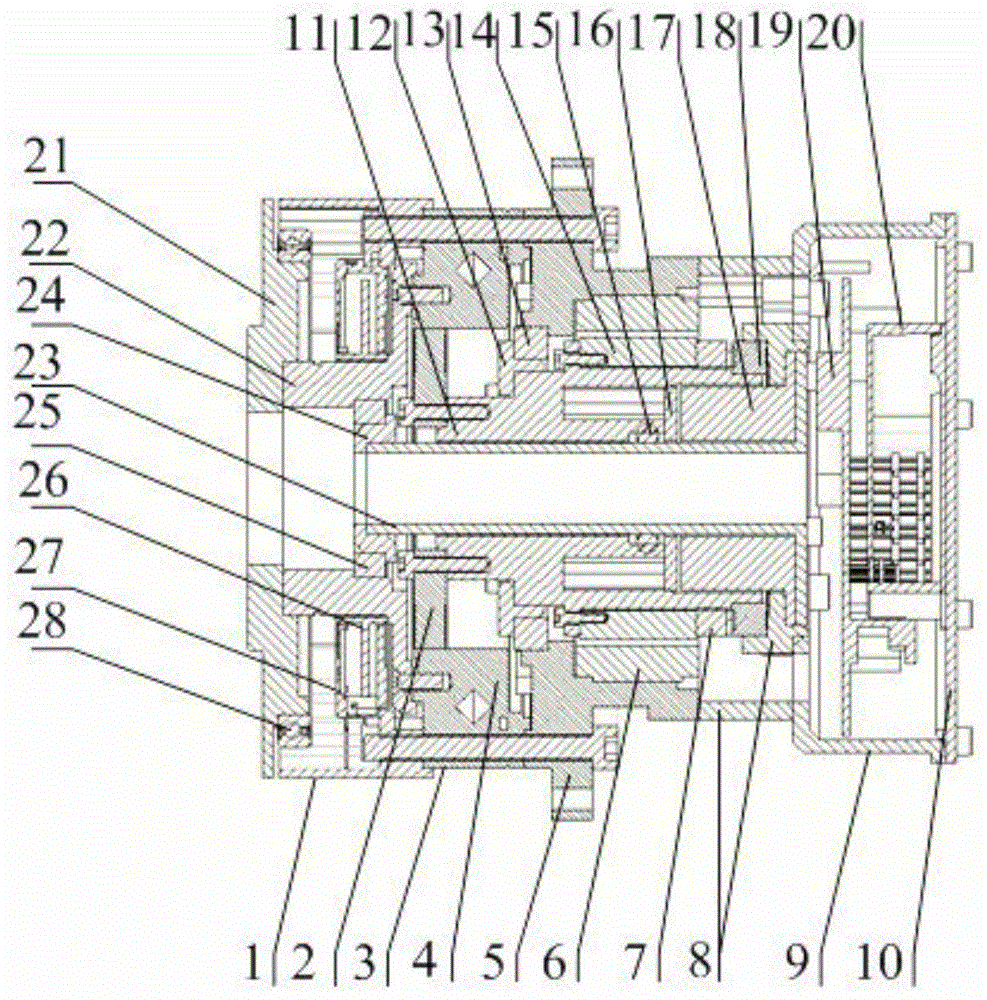

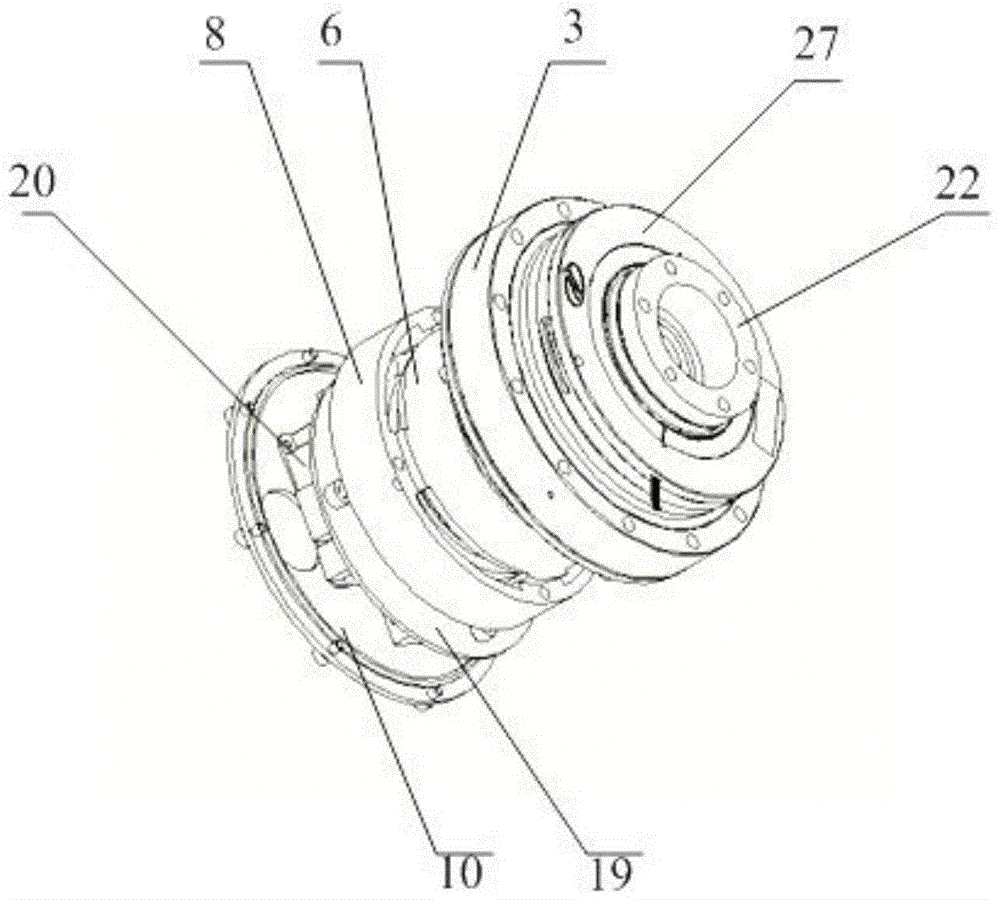

[0053] Such as Figure 1 to Figure 16 As shown, a modular joint of a dual-arm robot with a hollow structure in the present invention includes: a motor, an input device, an output device, a hollow brake, an absolute encoder, and a harmonic reducer.

[0054]The input device is fixed by flange I5, including: hollow motor rotor 14, rotor axial positioning sleeve 7, second motor bearing 18, hollow brake rotor 16, O-shaped sealing ring 15, first motor bearing 13, bearing Gland 12 and harmonic reducer wave generator 2;

[0055] The output device includes: joint output flange 21, output bearing 28, DS90 mounting flange 22, absolute encoder rotor 26, sealed bearing 25 and harmonic reducer steel wheel 3;

[0056] The input device and the output device are connected through the main transmission shaft 11;

[0057] Such as figure 2 As shown, the motor stator 6 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com