A mechanical lock device for connection and positioning

A mechanical lock and guide positioning technology, which is applied to mechanical equipment, connecting components, etc., can solve the problems of high cost and complex structure, and achieve the effect of large load-to-weight ratio, simple structure, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

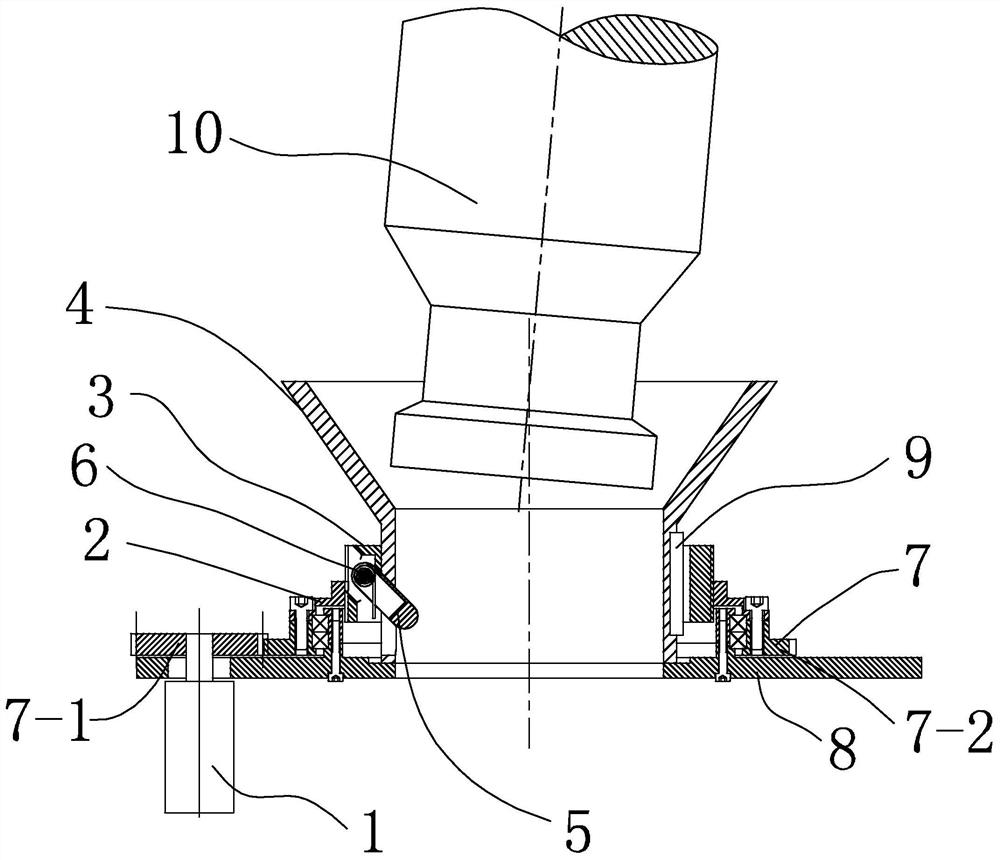

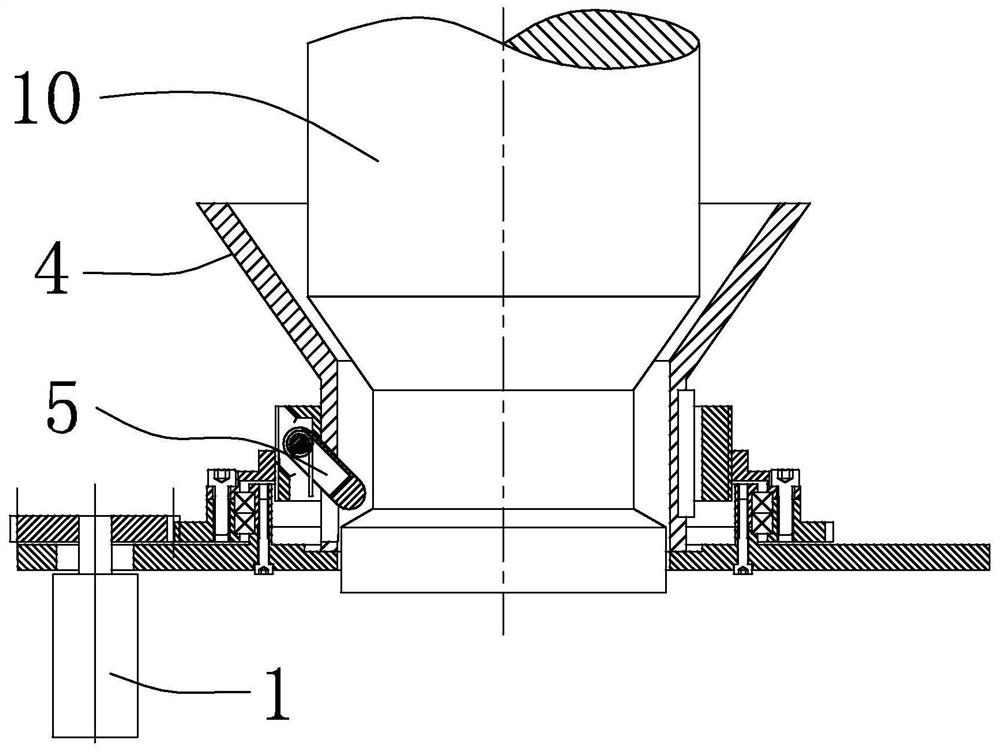

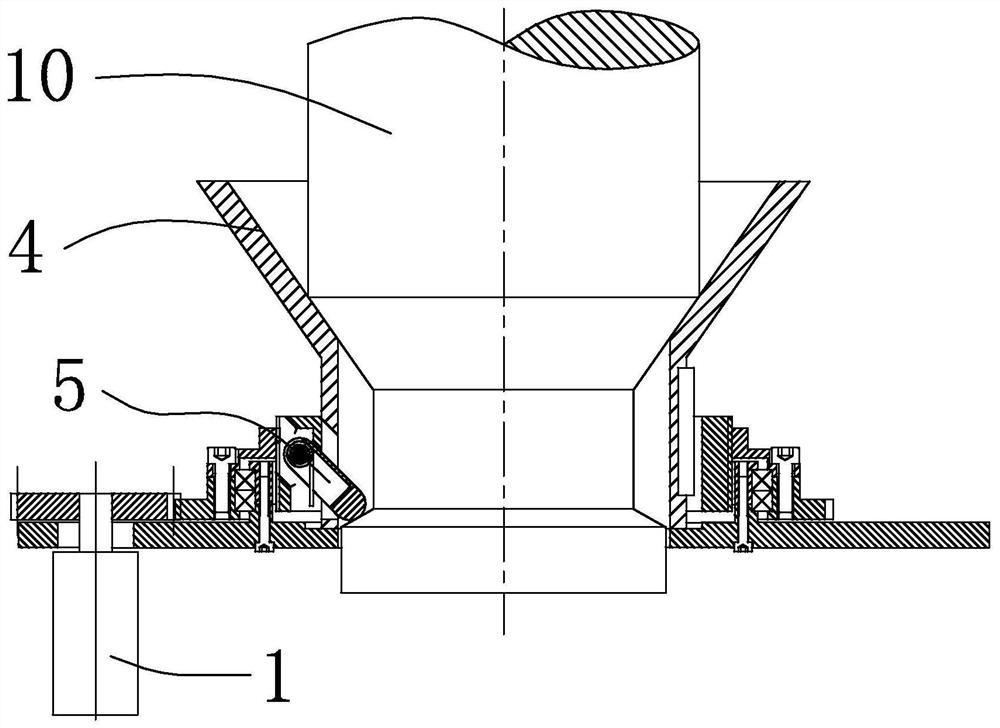

[0020] Specific implementation mode one: combine figure 1 To illustrate this embodiment, this embodiment includes a motor 1, a nut 2, a screw sleeve 3, a guide positioning cylinder 4, a torsion spring 6, a transmission device 7, a base 8 and a plurality of dead bolts 5;

[0021] The motor 1 and the guide and positioning cylinder 4 are respectively fixed on the base 8, the screw sleeve 3 is slidably fitted on the outside of the guide and positioning cylinder 4, the nut 2 is rotated on the base 8 through the transmission device 7 and is threaded with the screw sleeve 3 Cooperate, the motor 1 drives the nut 2 to rotate through the transmission device 7, and each dead bolt 5 is hinged on the screw sleeve 3 by a torsion spring 6, and a plurality of dead bolts 5 are equally distributed on the circumference of the screw sleeve 3, and a plurality of dead bolts 5 Can stretch into the inside of guide positioning cylinder 4.

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the transmission device 7 in this embodiment includes a driving gear 7-1 and a driven gear 7-2;

[0023] The driving gear 7-1 is connected with the shaft of the motor 1, the driven gear 7-2 is rotated and arranged on the base 8, the driving gear 7-1 and the driven gear 7-2 mesh with each other, and the nut 2 is fixed Connected to the driven gear 7-2, and the nut 2 is arranged concentrically with the driven gear 7-2.

[0024] The present invention adopts gear transmission to ensure the transmission ratio. The position of the screw sleeve 3 is measured by a position sensor such as a potentiometer and transmitted to the input terminal of the PLC. The output terminal of the PLC controls the start and stop of the motor 1 to realize the locking and release of the workpiece 10. The present invention can realize the locking and releasing of the workpiece 10 without particularly high precision...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the circumference of the screw sleeve 3 in this embodiment is processed with a plurality of notches, and a lock tongue 5 is arranged in each notch. When the workpiece is in an unlocked state, each groove on the screw sleeve 3 Dead bolt 5 in the mouth is all pressed by torsion spring 6 and is in open state.

[0027] Such arrangement makes it possible for the plurality of lock tongues 5 to change the swinging angle when the screw sleeve 3 passes through the workpiece 10 or the guide positioning cylinder 4, so that the workpiece 10 is in a locked or released state.

[0028] Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com