Integrated joint module of compact robot and compact robot

A robot and compact technology, applied in the field of robots, can solve the problems of excessive size, poor bearing capacity and dynamic performance of the integrated joint module, and achieve the effects of good rigidity, high integration, and improved bearing capacity and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

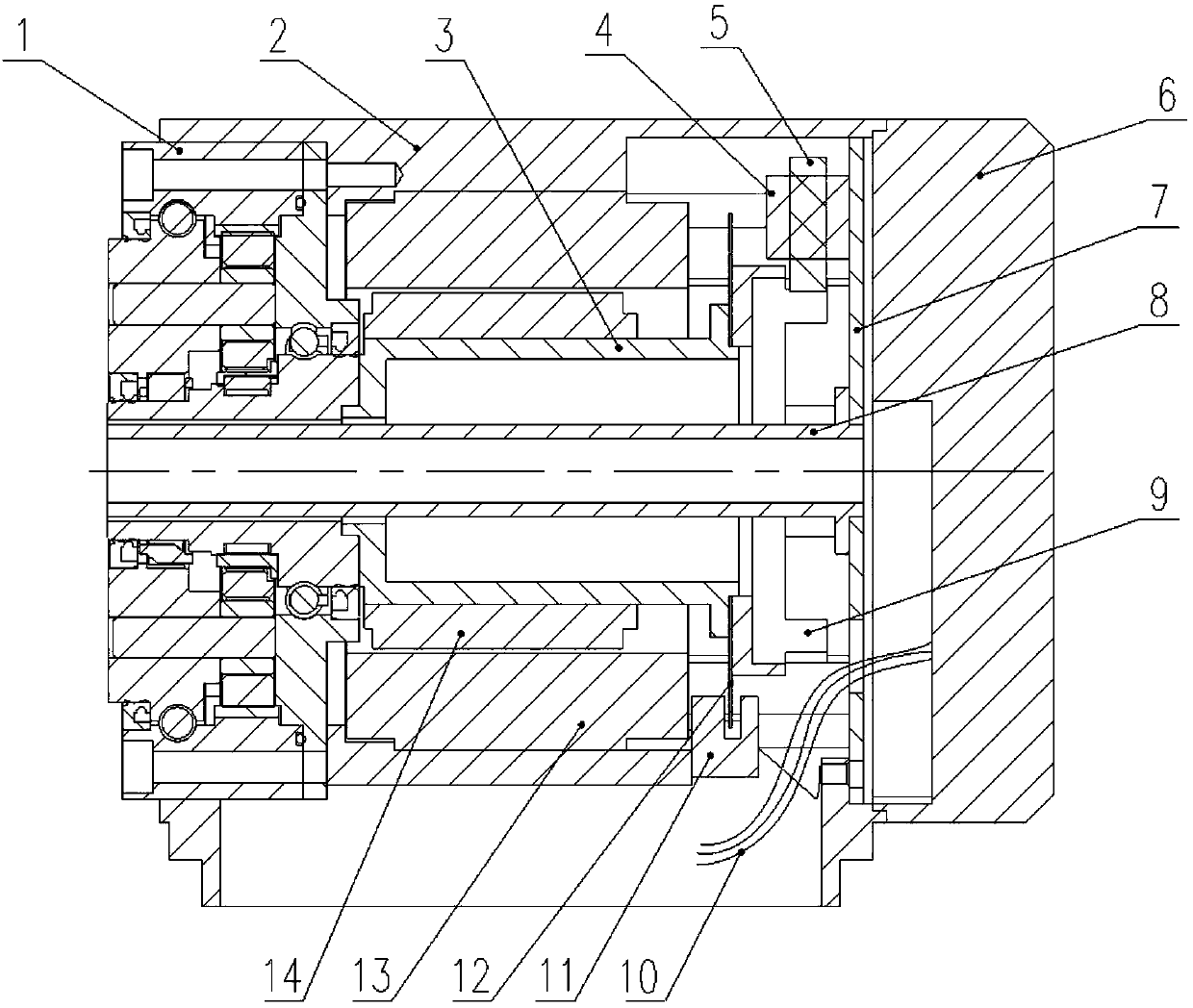

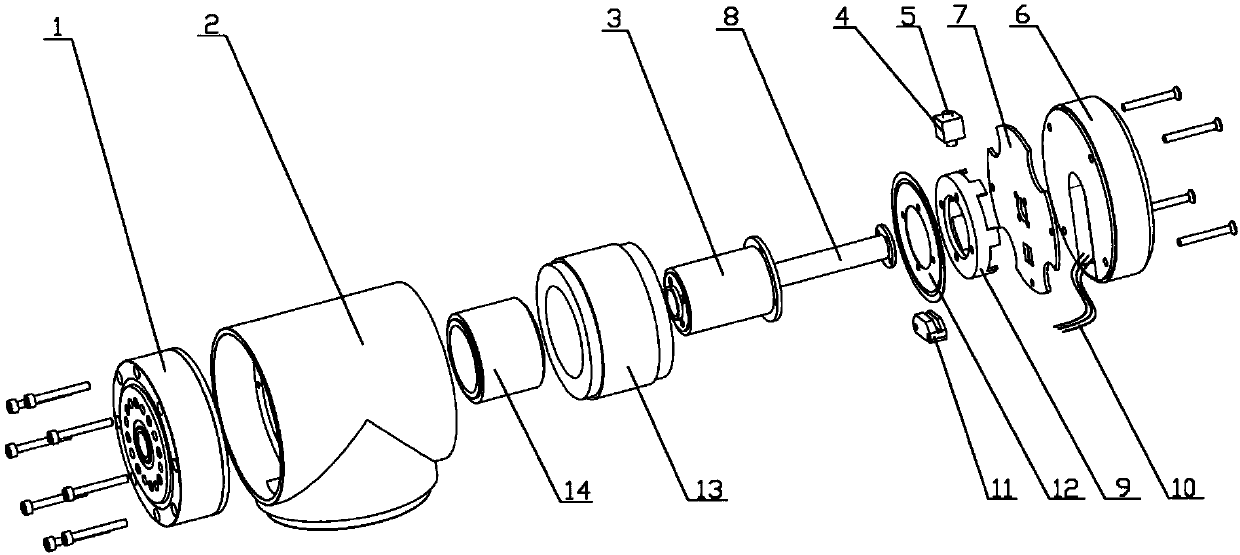

[0030] combined with figure 1 and figure 2 , a compact robot integrated joint module of the present invention, including a cycloidal pinwheel reducer 1, a housing 2, a shaft 3, an electromagnetic actuator 4, a movable pin 5, an integrated circuit module 6, an end cover 7, a wire Cable protection sleeve 8, claw brake disc 9, cable 10, photoelectric encoder read head 11, photoelectric encoder disc 12, motor stator 13 and motor rotor 14;

[0031] The cycloid reducer 1, the shaft 3, the photoelectric encoder disk 12, the motor stator 13 and the motor rotor 14 are coaxial;

[0032] The cycloidal pinwheel reducer 1 is fixed on the front end of the housing 2, the motor stator 13 is fixed in the housing 2, the motor rotor 14 is fixedly connected to the shaft 3, and the front end of the shaft 3 is decelerated with the cycloidal pinwheel The input end of the device 1 is fixedly connected, and the rear end of the shaft 3 is fixedly connected with the photoelectric encoder disc 12 and ...

Embodiment 2

[0035] combined with figure 1 and figure 2 , the difference from Embodiment 1 is that, further, it also includes a cable protective cover 8, the cycloidal pinwheel reducer 1 is a hollow structure, and the cable protective cover 8 runs through the cycloidal needle from front to back in sequence Wheel reducer 1, shaft 3 and end cover 7 are located inside cycloidal pinwheel reducer 1, shaft 3 and end cover 7, and the front end of cable protection sleeve 8 is fixedly connected with cycloidal pinwheel reducer 1 , the rear end is connected to the end cover 7, and the signal wires and power wires can pass through the cable protection sleeve 8 from the front end for wiring arrangement, which can protect the cables passing through the central hole of the integrated joint module.

Embodiment 3

[0037] combined with figure 1 and figure 2 , the difference from Embodiment 2 is that, further, the braking device includes an electromagnetic actuator 4, a movable pin 5 and a claw brake disc 9, and the claw brake disc is fixed on the rear end of the shaft 3 and is located on the photoelectric encoder disc 12, the electromagnetic actuator 4 is fixed on the end cover 7 and is located inside the housing 2, and the movable pin 5 is arranged on the electromagnetic actuator 4 and moves axially under the drive of the electromagnetic actuator 4. A circle of convex teeth is uniformly distributed along the axial direction on the circumference of the moving disk 9, and the movable pin 5 moves along the axis to insert into the convex teeth or retract.

[0038] The electromagnetic actuator 4 makes the moving pin 5 move along its own axis; when the electromagnetic actuator 4 eliminates the suction force, the moving pin 5 protrudes and gets stuck between the convex teeth of the claw brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com