Drive control integration intelligent integrated joint

A technology of drive control and joints, which is applied in the field of robotics, can solve the problems of low integration, low load to weight ratio, and large joint volume, and achieve the effects of high integration, simple wiring, and simplified transmission lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0020] The drive-control-integrated intelligent integrated joint according to the present invention can be used as a joint component in industrial robots and industrial manipulators in a narrow sense, or in a generalized robot, that is, a machine device that automatically performs work.

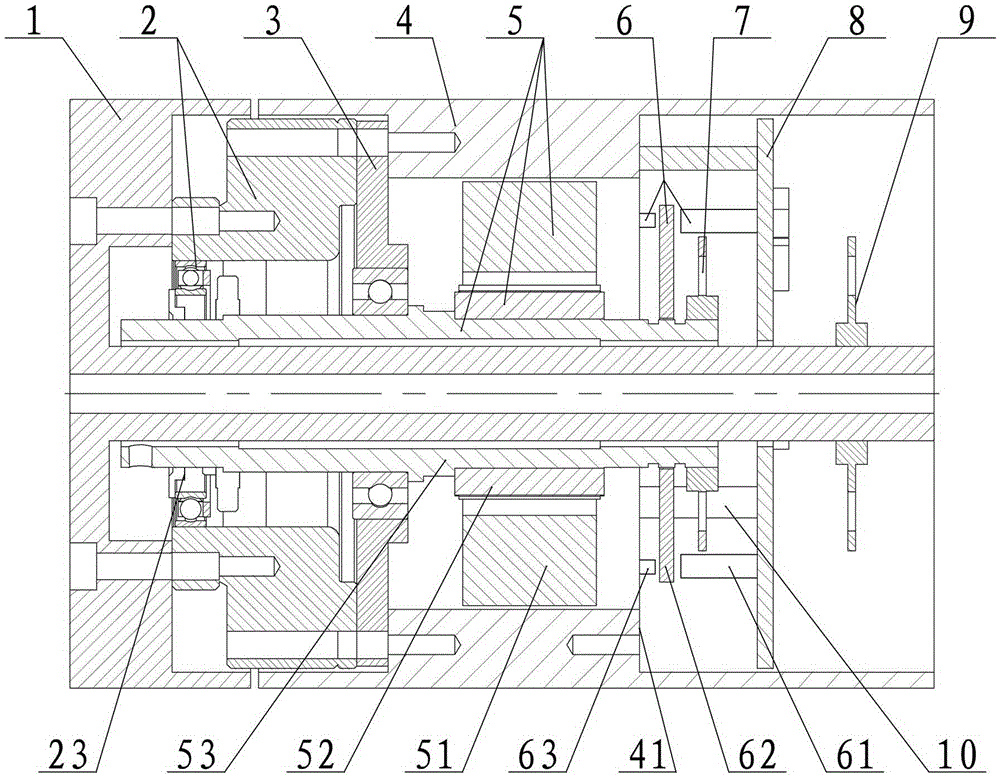

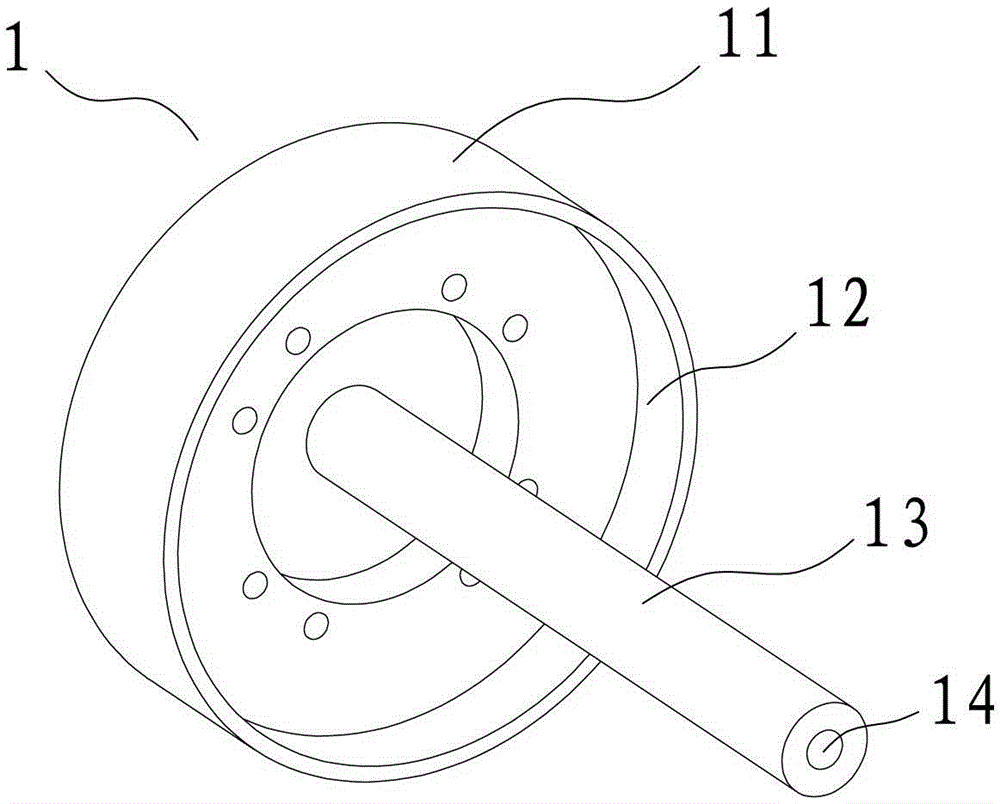

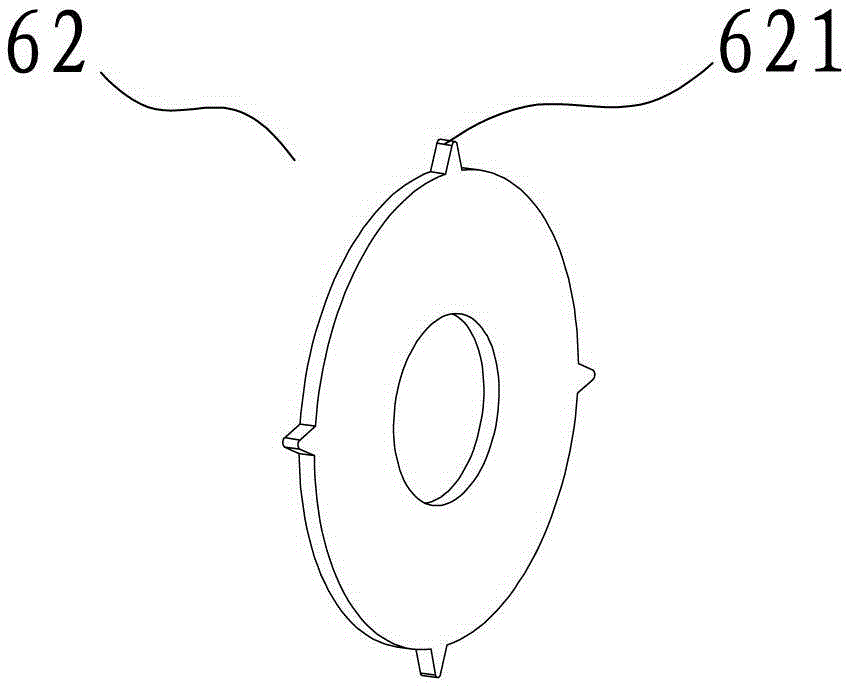

[0021] Reference figure 1 In the first embodiment, the housing part of the drive control integrated intelligent integrated joint according to the present invention is composed of the joint output member 1 and the joint housing 4, and the joint output member 1 can rotate relative to the joint housing 4. The joint housing 4 is a cylindrical hollow tubular structure, and its outer diameter is basically the same as that of the joint output member 1. Inside the joint h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com