A double-thread underactuated multi-fingered robot end effector driven by a single motor and method thereof

An end effector, single-motor drive technology, which is applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of replacing different end effectors, achieve the effect of improving the load-to-weight ratio, solving jamming, and simplifying the mechanism and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

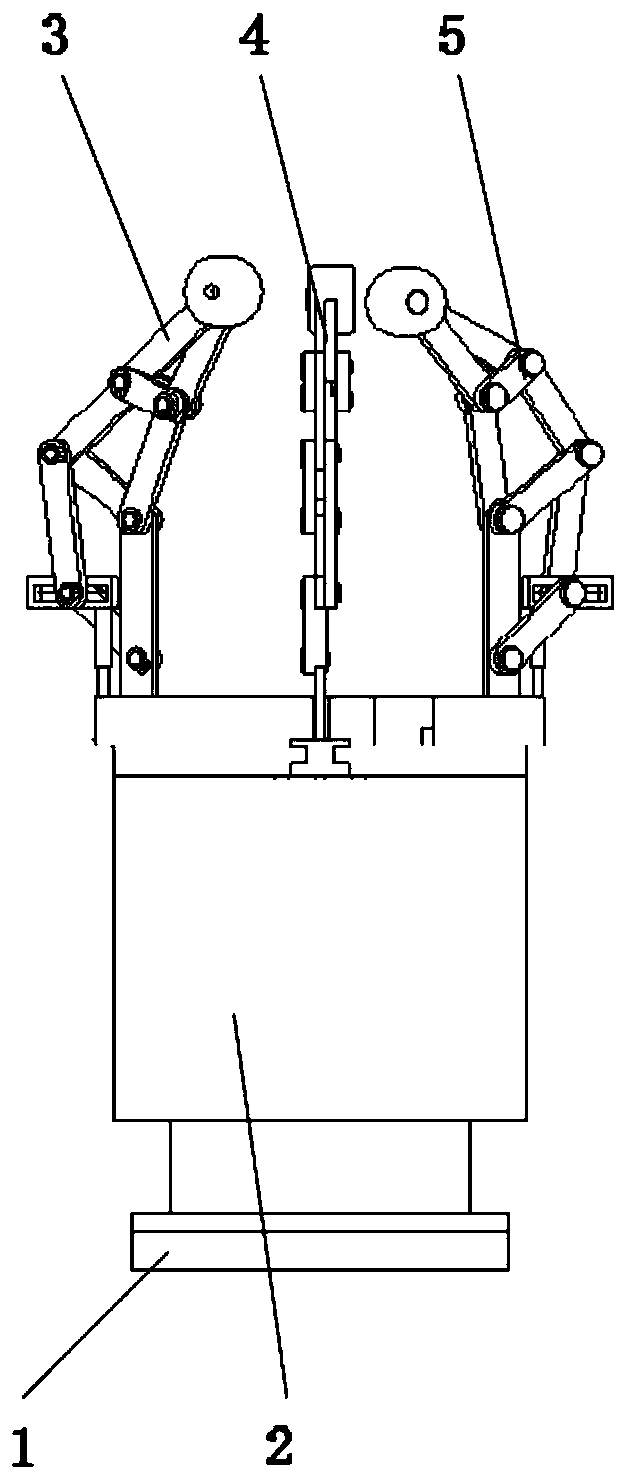

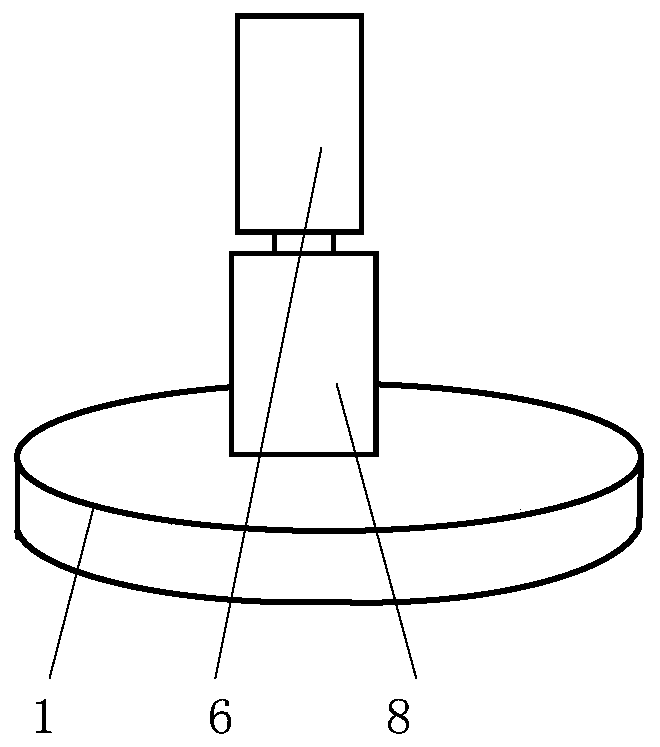

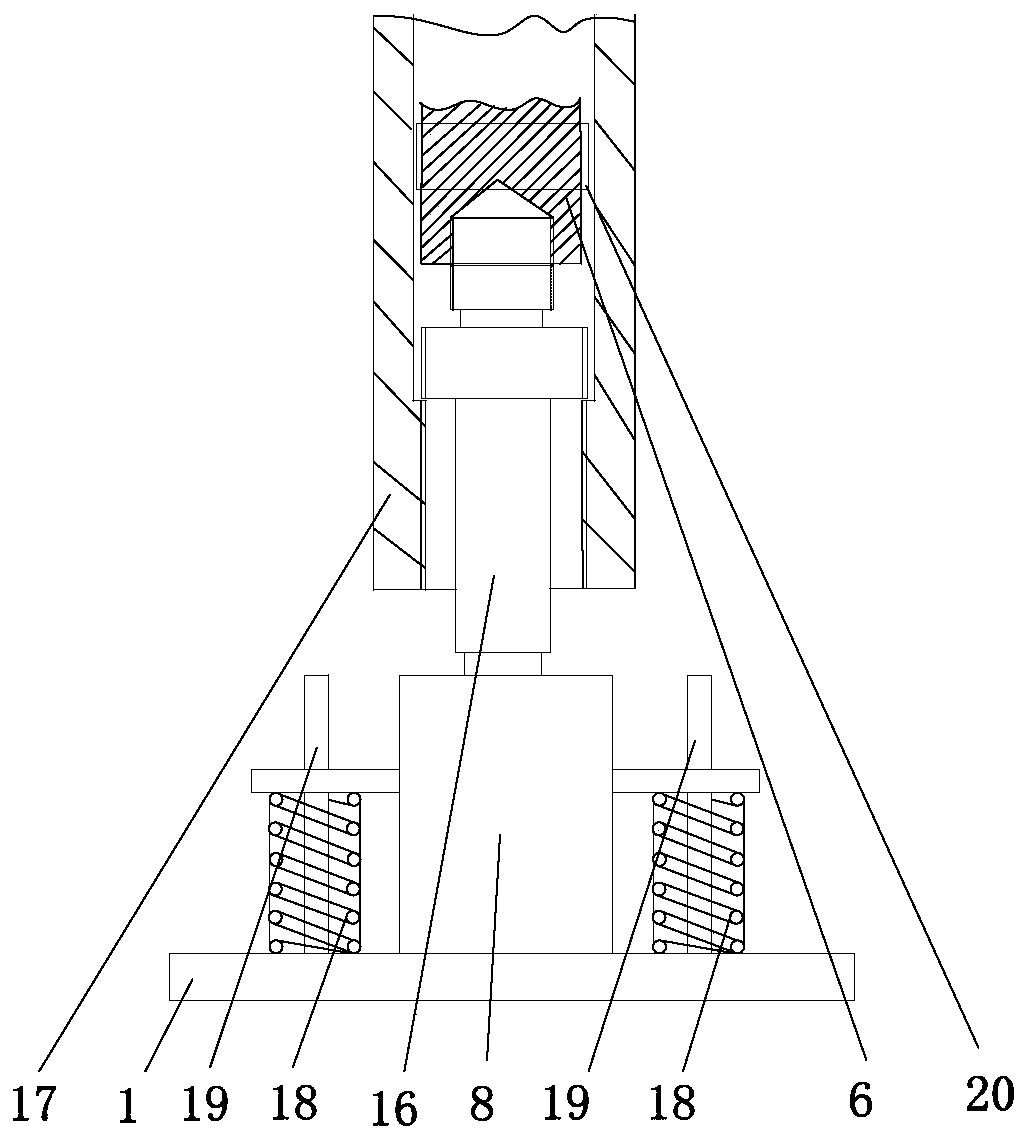

[0034] Aiming at the deficiencies of the prior art, the present invention proposes a double-threaded underactuated multi-fingered robot end effector driven by a single motor and a method thereof. A single motor drives a double-threaded transmission rod to complete the gathering, loosening and grasping and releasing of the end effector. This kind of action solves the problem that the existing end effector grabs the object with single diameter and complex structure. It has a single motor to realize two-dimensional movement, and the driving system is simple. It can use one end effector to achieve a wide range of grabbing diameters. The advantages of the object, the present invention will be explained and illustrated in more detail below in conjunction with the accompanying drawings.

[0035] Such as figure 1 Shown is an overall view of the end effector of a double-threaded underactuated multi-fingered robot driven by a single motor; figure 2 Shown is a view of the motor in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com