Dual-material multi-protection sealing mechanism of ball valve

A technology of multiple protection and sealing mechanisms, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of insignificant effect and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present application and actual conditions.

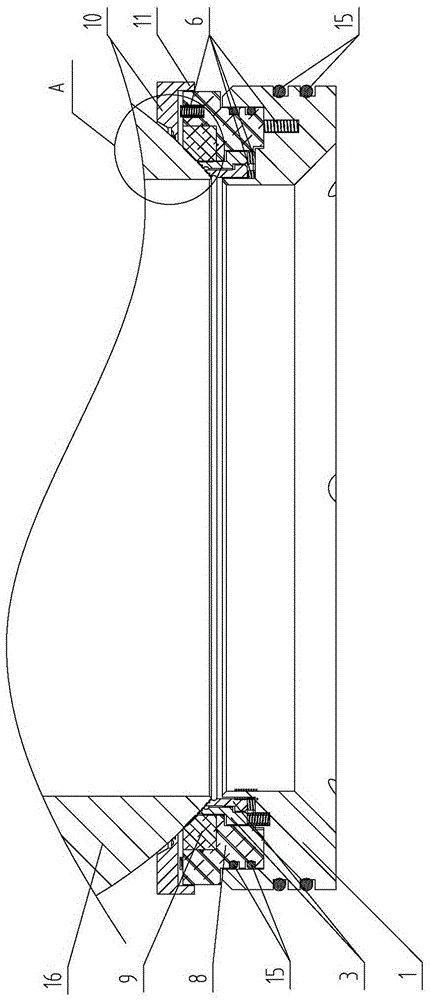

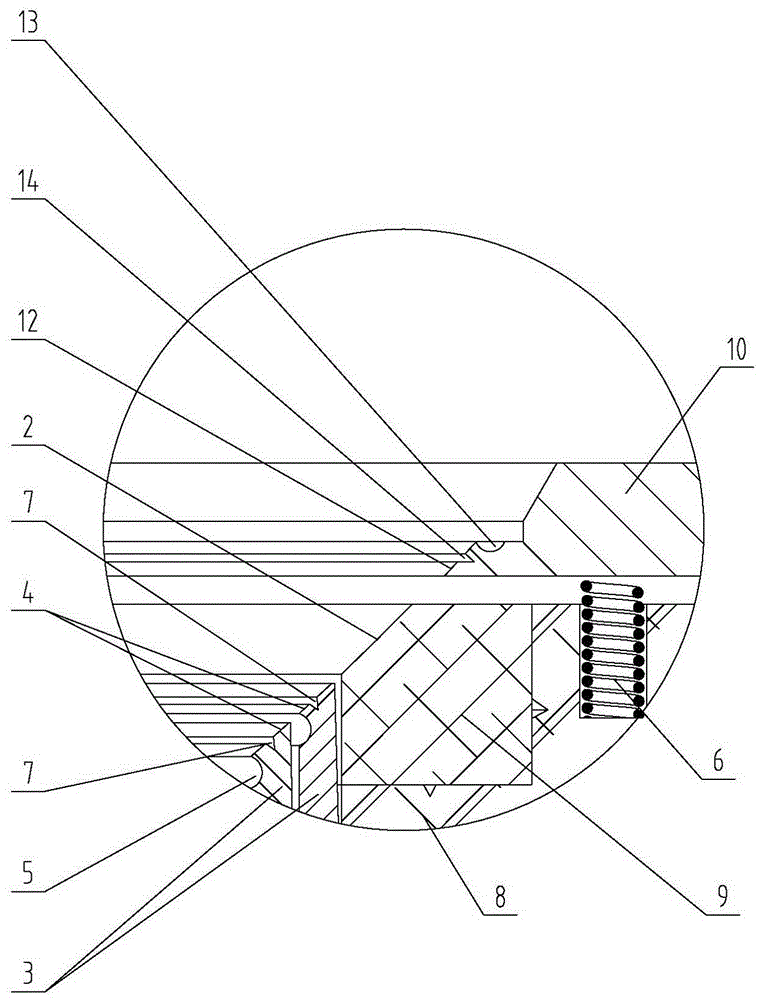

[0017] Such as figure 1 , 2 As shown, the double-material multiple-protection sealing mechanism of the ball valve includes an annular sealing valve seat 1 and a soft sealing assembly installed on the annular sealing valve seat 1. The soft sealing assembly is provided with a soft sealing surface that matches the surface of the ball 16 of the ball valve. 2. At least one first hard sealing ring 3 is installed on the annular sealing valve seat 1, and the first hard sealing ring 3 is provided with a first hard sealing ring that matches the surface of the ball 16 of the ball valve and is located inside the soft sealing surface 2. Hard sealing surface 4, on the end surface of the first hard sealing ring 3 which is adjacent to the first hard sealing surface 4 and located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com