Explosion-proof capacitor

A capacitor and negative electrode technology, applied in the field of explosion-proof capacitors, can solve problems such as potential safety hazards, shorten the service life of capacitors, and explosion, and achieve the effects of solving solder joints that are easily affected by temperature, improving electrical performance, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

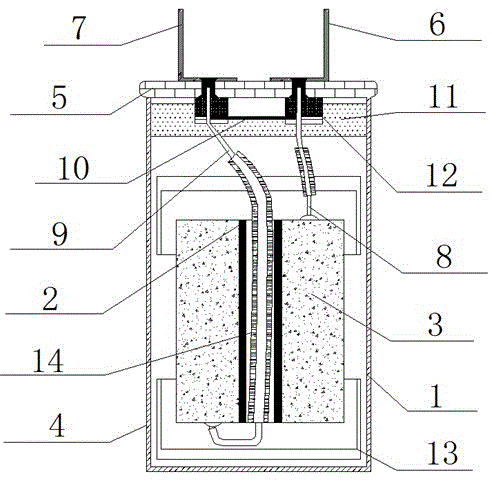

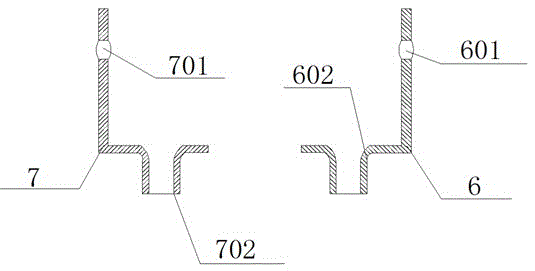

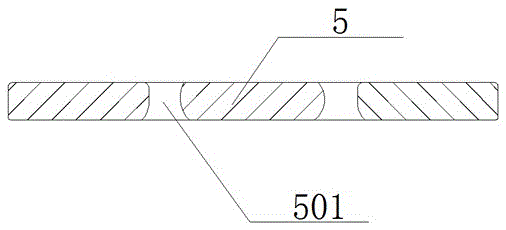

[0020] like Figure 1 to Figure 4 The shown explosion-proof capacitor includes a shell 1, an explosion-proof end cover 5, a positive electrode pin 6 and a negative electrode pin 7, the shell 1 is wrapped with a layer of plastic film 4, and two A vertical mandrel 2 and a polypropylene film layer 3, the polypropylene film layer 3 is wound on the outside of the corresponding mandrel 2, an explosion-proof end cover 5 is sealed and installed on the top of the housing 1, and the explosion-proof end cover 5 is symmetrically arranged Two mounting holes 501, the positive electrode pin 6 and the negative electrode pin 7 pass through the two mounting holes 501 on the explosion-proof end cover 5 and are respectively connected to the positive electrode wiring 8 and the negative electrode wiring 9, and the positive electrode wiring 8 is connected to The top end of the polypropylene film layer 3, the negative electrode connection 9 is connected to the bottom end of the polypropylene film lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com