Sealing, locking and grounding structure at wire inlet of non-explosion-proof motor junction box

A technology for explosion-proof motors and junction boxes, which is applied in the direction of electrical components, electromechanical devices, and electric components, etc. poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

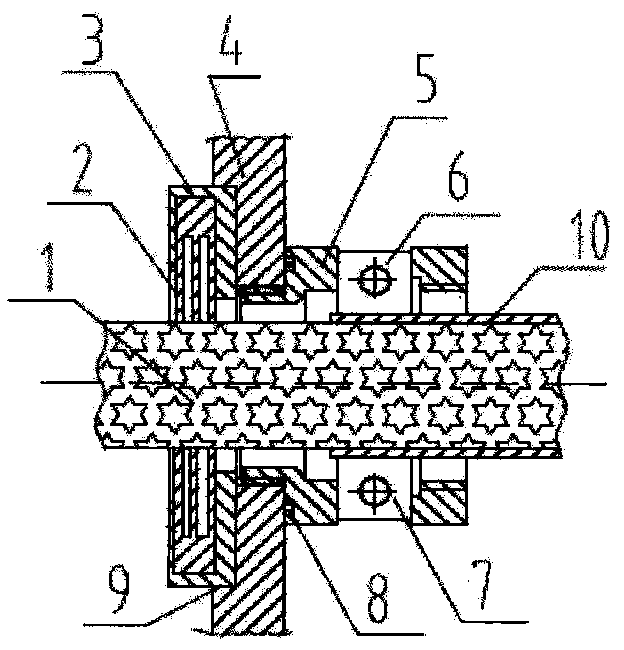

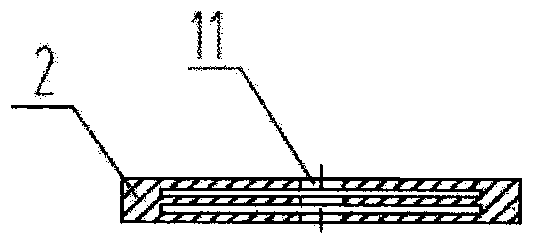

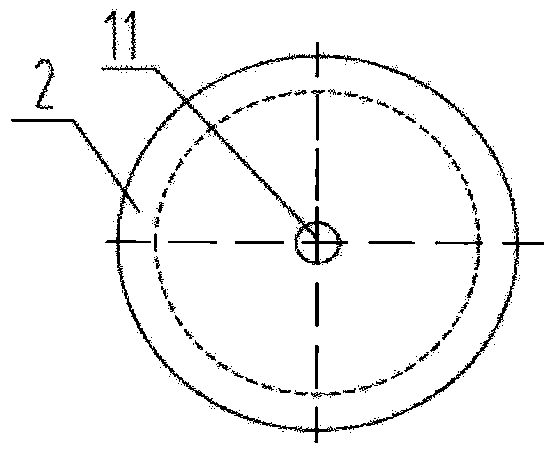

[0012] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A sealed and locked grounding structure at the inlet of a non-explosion-proof motor junction box is composed of: cable 1, elastic sealing ring 2, card slot 3, junction box seat 4, Junction bucket 5, metal locking ring 6, metal grounding ring 7, O-ring 8, seam 9, armor layer 10, reserved hole 11, locking bolt 12, locking nut 13, grounding bolt 14, grounding nut 15 poses. The elastic sealing ring 2 is a multi-layer semi-permeable groove structure, and there is a reserved hole 11 in the multi-layer semi-permeable groove structure. The elastic sealing ring 2 is installed in the card slot 3, and the card slot 3 is embedded in the junction box seat 4 On the reserved seam 9, the O-ring 8, the metal locking ring 6, and the metal grounding ring 7 are sequentially inserted into the junction box 5, and the junction box 5 is screwed on the junction box seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com