Autonomous firing line shearing device

A cutting device and autonomous technology, applied in the mechanical field, can solve the problems of high manufacturing cost, complicated mechanism of falling off plugs, damage to the connection of ignition wires, etc., and achieve the effect of wide range of wire diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

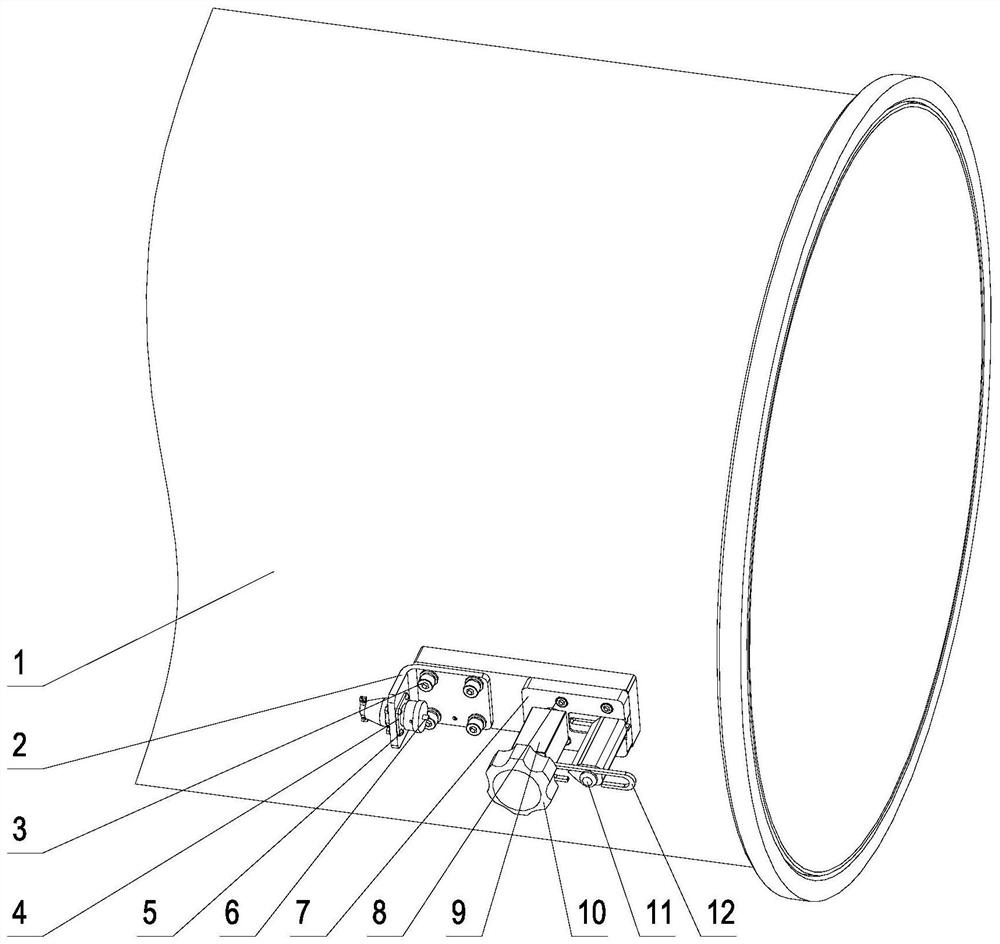

[0037] This embodiment provides an autonomous firing wire cutting device, which can cut off the firing wire autonomously, avoid damage to the connection of the firing wire at the end of the launch tube, effectively control the separation of the carrier (ammunition) from the launch tube, and be safe and reliable in use.

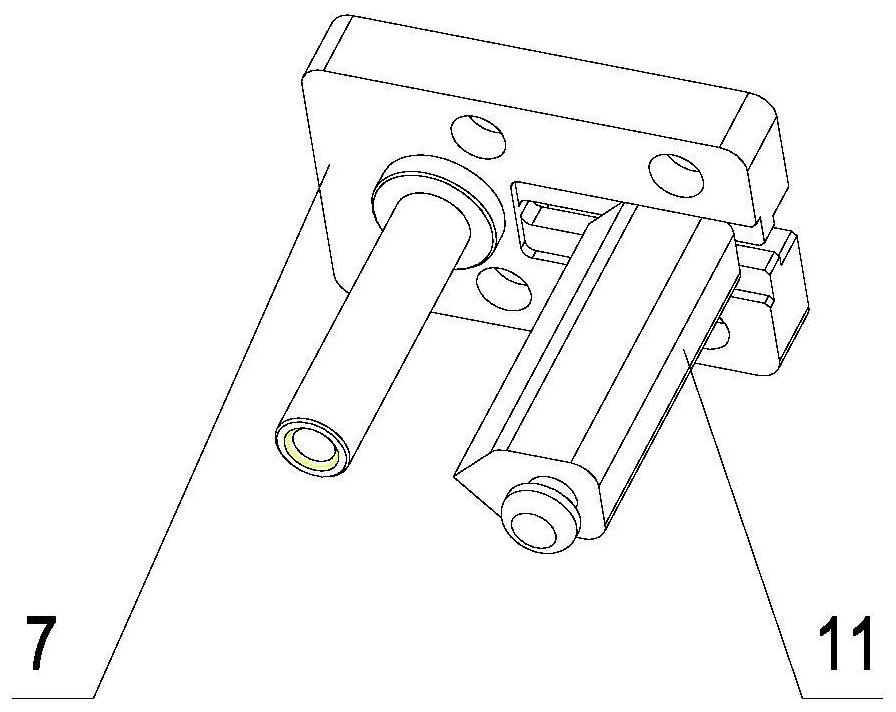

[0038] Such as Figure 1-Figure 7 As shown, the shearing device is installed on the launch tube 1, including: a connector mounting seat 2, a socket 4, a seat body 7, a square column 9, a handle 10, a side blade body 11 and a wire retaining plate 12; a fire wire plug 14 It is integrally connected with the ignition wire 15, and the ignition wire 15 is connected with the cutting device through the ignition wire plug 14.

[0039] specific:

[0040] A boss is left on the outer circumference of the launch tube 1, and eight screw holes for installing the shearing device are left on the boss;

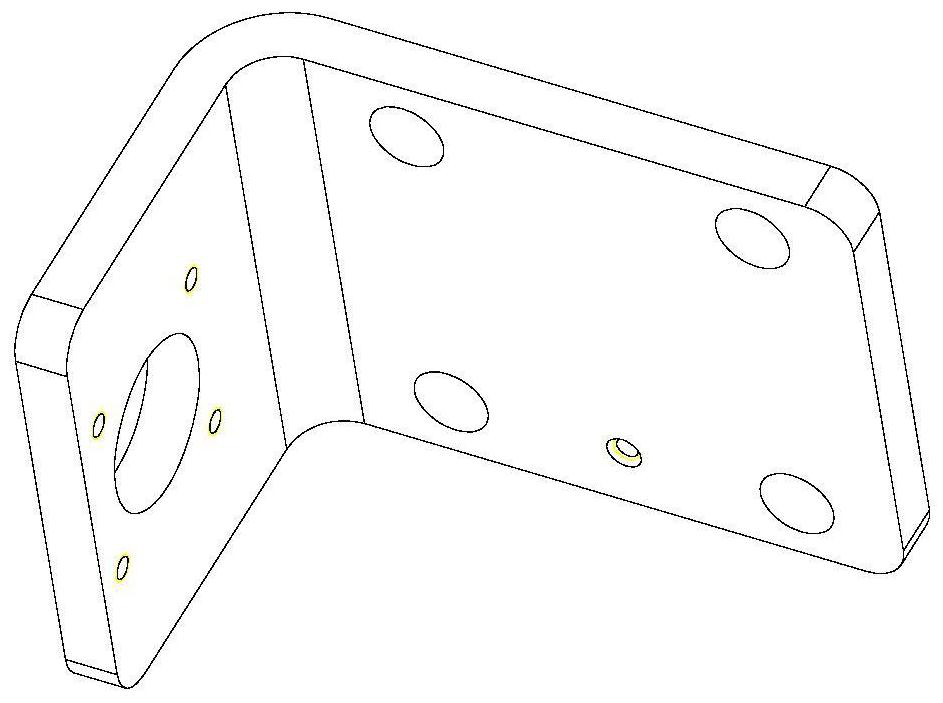

[0041] Such as figure 2 As shown, the connector mounting seat 2 is a 9...

Embodiment 2

[0057] On the basis of the above-mentioned embodiment 1, because the cutting device utilizes the change of the gap between its side and the side blade body 11 when the square column 9 rotates to realize the shearing of the blade of the side blade body 11 to the firing line 15, therefore the Replacing the square column 9 with other rotary structures (i.e. rotating bodies) with different wall thicknesses along the circumferential direction can also achieve the purpose of automatically cutting the firing line 15, such as a cam; the distance between the side blade body and the rotating body ensures: When the side with the smallest wall thickness of the rotating body was opposite to the side where the blade of the side blade body was located, the blade of the side blade body did not touch the firing line between the side blade body 11 and the rotating body; When the side where the edge of the blade body is located is opposite, the blade of the side blade body can cut off the firing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com