Natural gas liquefaction exchange pressure regulator

A pressure regulator and natural gas technology, applied in safety valves, engine components, balance valves, etc., can solve problems such as inconvenience in production and management, increased costs, and LP outlet pressure exceeding the tolerance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

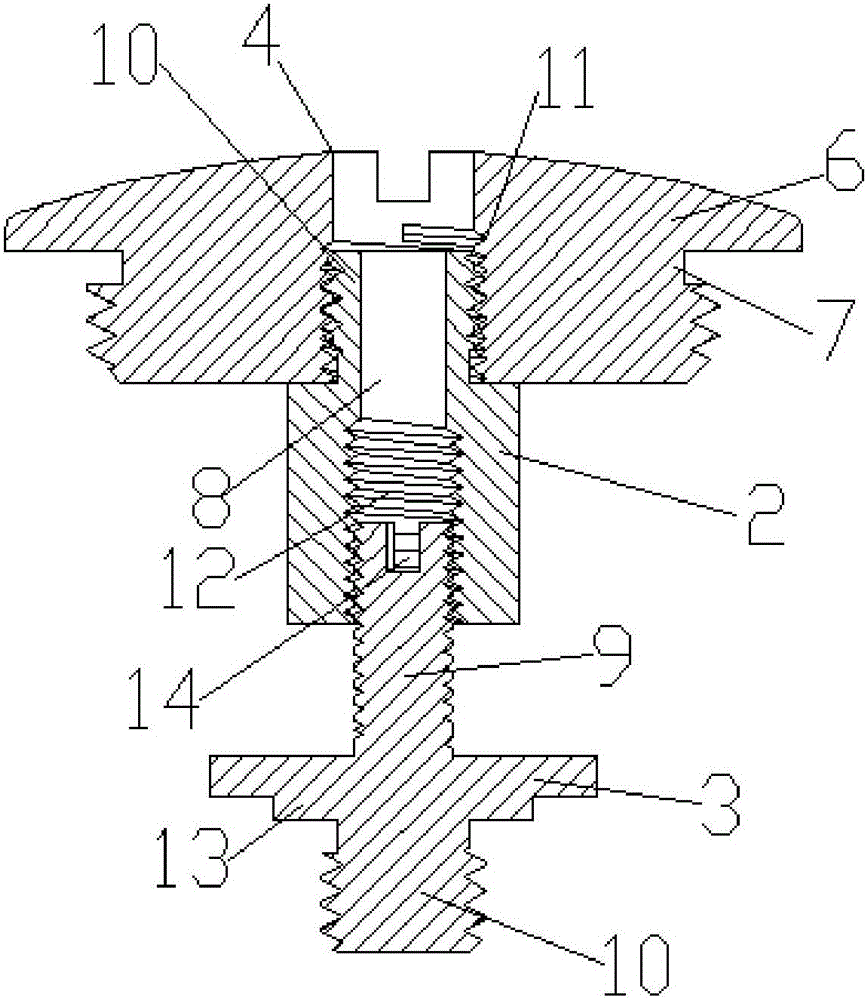

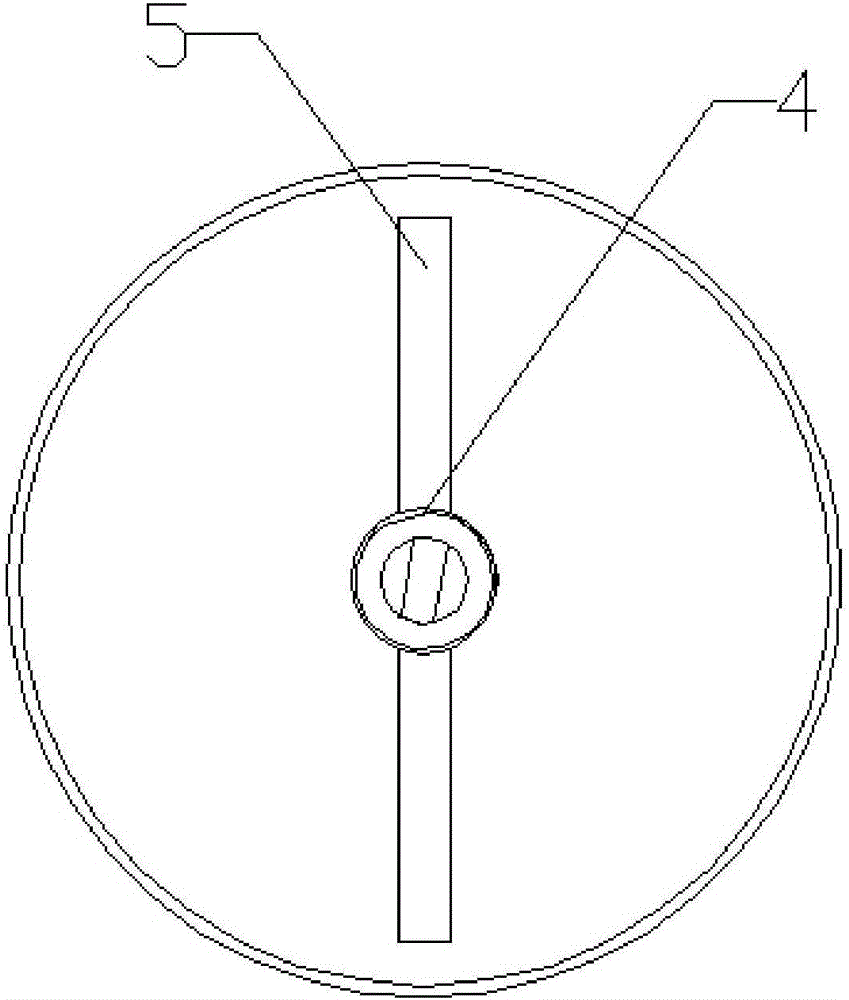

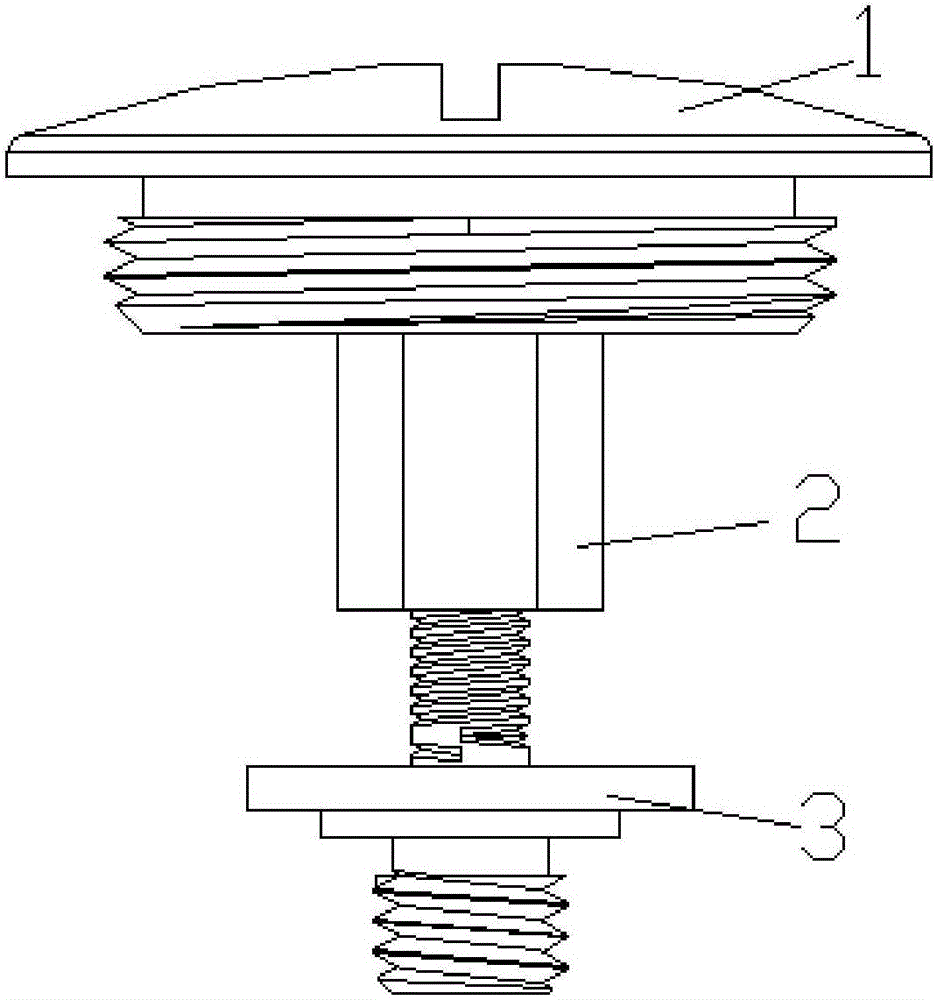

[0025] The pressure regulating rod in the device is composed of connecting rod 2 and pressure plate 3. When the elastic force of the pressure regulating spring of the same specification deviates, the length of the pressure regulating rod can be adjusted by controlling the depth of the threaded rod 9 extending into the second threaded hole 12 Thereby controlling the elastic force of the pressure regulating spring, a kind of pressure regulating spring can also be used under the situation of different outlet air pressures and different flow rates, and the length of the pressure regulating rod can be changed to change the pressure regulating spring. It can be visually judged whether the factory state of the pressure regulator is NG or LP through the circular through hole 4 arranged on the upper end surface of the pressure cap 6 . LP status as image 3 As shown, the NG state is as Figure 4 shown.

[0026] When the device is in the LP state and the length of the pressure regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com