Split combined type tower crane wall attaching frame and installation method thereof

A combined type and wall-mounted technology, which is applied to cranes and other directions, can solve the problems that the shaft cannot be reused, has no applicability, and the shaft is shortened, so as to improve the tensile strength and structural stability, ensure stability, The effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

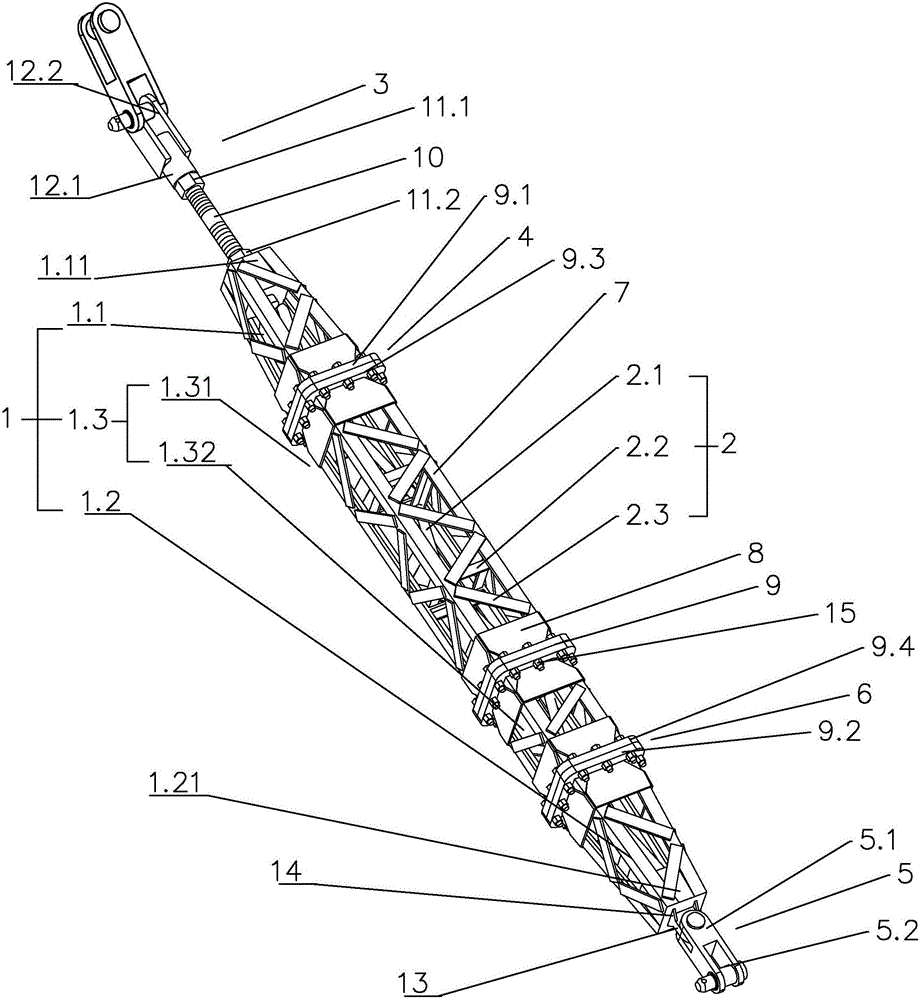

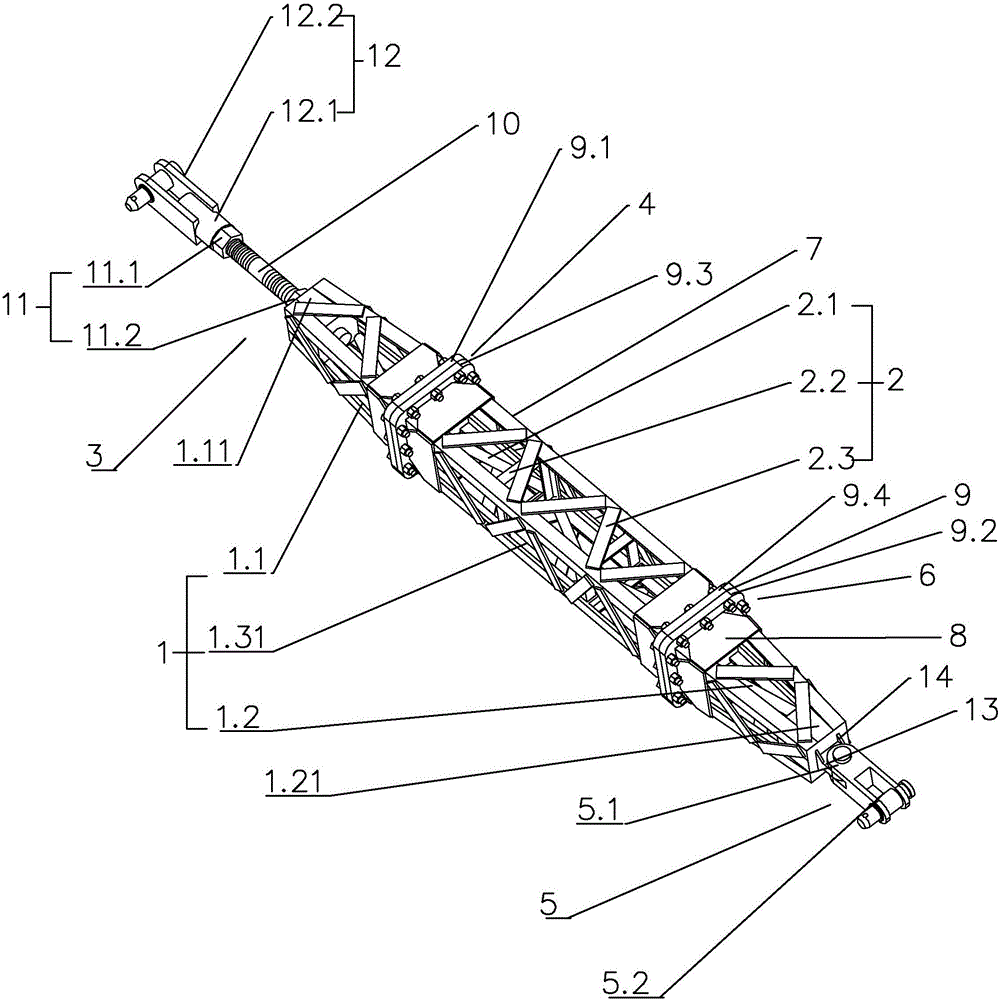

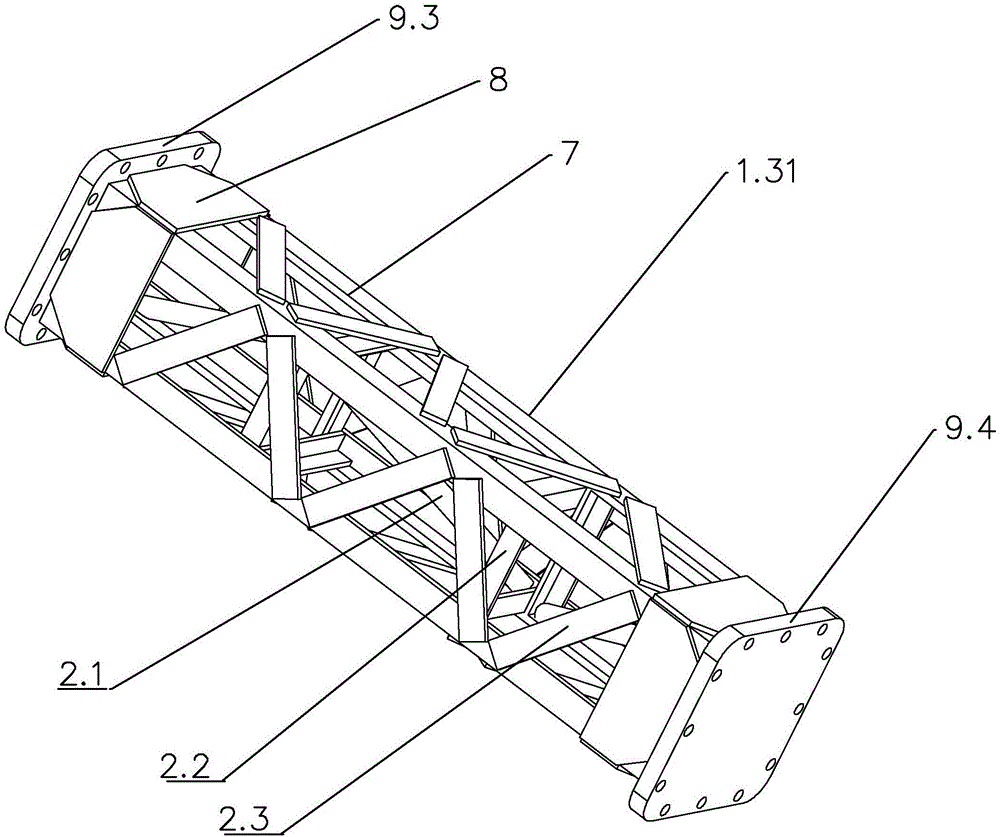

[0043] 1. Reference figure 1 , image 3 , Figure 4 The first embodiment of the present invention will be further described.

[0044] The specific structure and connection relationship of the first embodiment of the split combined tower crane attached wall frame are as follows: a split combined tower crane attached wall frame is connected between the wall body 16 of the building and the tower body 17 of the tower crane, including an attached Wall tie rod body 1, the wall tie rod body 1 includes a first end connecting rod 1.1, a second end connecting rod 1.2 and several shaft sections 1.3 with different lengths connected together, and the shaft section 1.3 includes a long section 1.31 and a short section 1.32, wherein the length of the long section 1.31 is 1 meter or 2 meters or 3 meters or 4 meters or 5 meters, so that in different construction environments, the appropriate long section 1.31 can be selected for splicing according to the specific situation, increasing the app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com