Novel cavity power divider

A power divider and cavity technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of limited bandwidth, affecting production efficiency, and high processing precision requirements, so as to reduce processing precision and improve production efficiency. High simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

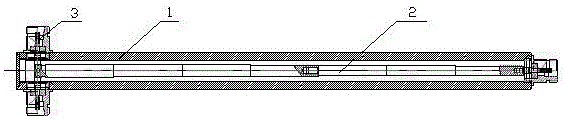

[0009] refer to figure 1 , a new cavity power splitter, which includes a housing 1, a power splitter 2, and a coupler 3, the housing 1 is provided with a power splitter 2, and the two ends of the power splitter 2 are connected to the coupler 3 pins, The shell 1 is connected with the shell of the coupler 3, and the power dividing rod 2 is divided into two sections, and the two sections are connected by threaded studs.

[0010] The power splitter 2 can be provided with 3-5 interfaces to connect with the connector 3 pins respectively.

[0011] In the present invention, a power distribution rod is arranged in the shell, and the power distribution rod is divided into two sections, one section is 1, 2, 3 grades, which is thinner, and the other section is 4, 5, 6, 7 grades, which is thicker, between the two sections It is screwed and connected to form a whole power sub-rod. Since the length of each section is shortened, the processing deformation is very small, thus ensuring the mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com