A strip planting method for mechanically harvesting millet without ear entanglement

A planting method and striping technology, applied in fertilization methods, fertilization devices, agriculture, etc., can solve problems such as ear entanglement, difficulty in adapting to mechanized harvesting, etc., to achieve enhanced lodging resistance, increased annual utilization rate, and increased edge row advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

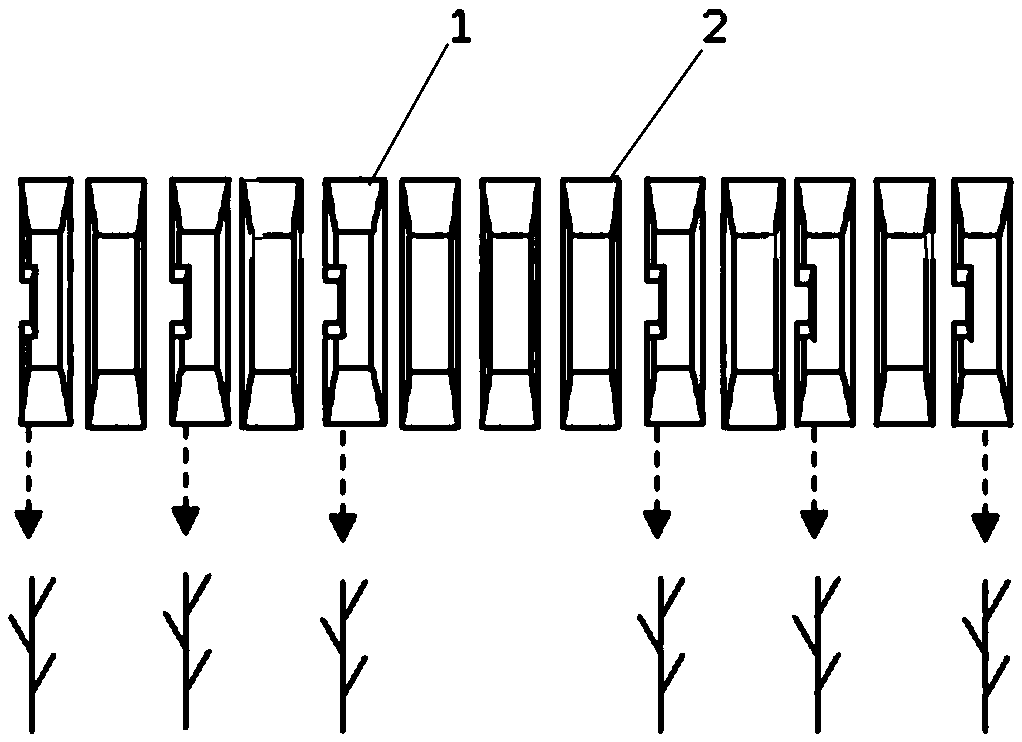

[0017] In June 2015, the method of the present invention was demonstrated in Han Village (Linfen Development Zone, Shanxi) in the experimental base of Wheat Research Institute of Shanxi Academy of Agricultural Sciences for 15 mu of millet re-sowing, with a planting width of about 240 cm and an interval of about 60 cm. During the millet harvest period (October 12, 2015), the grain ears between the side rows of two adjacent planting belts were not entangled.

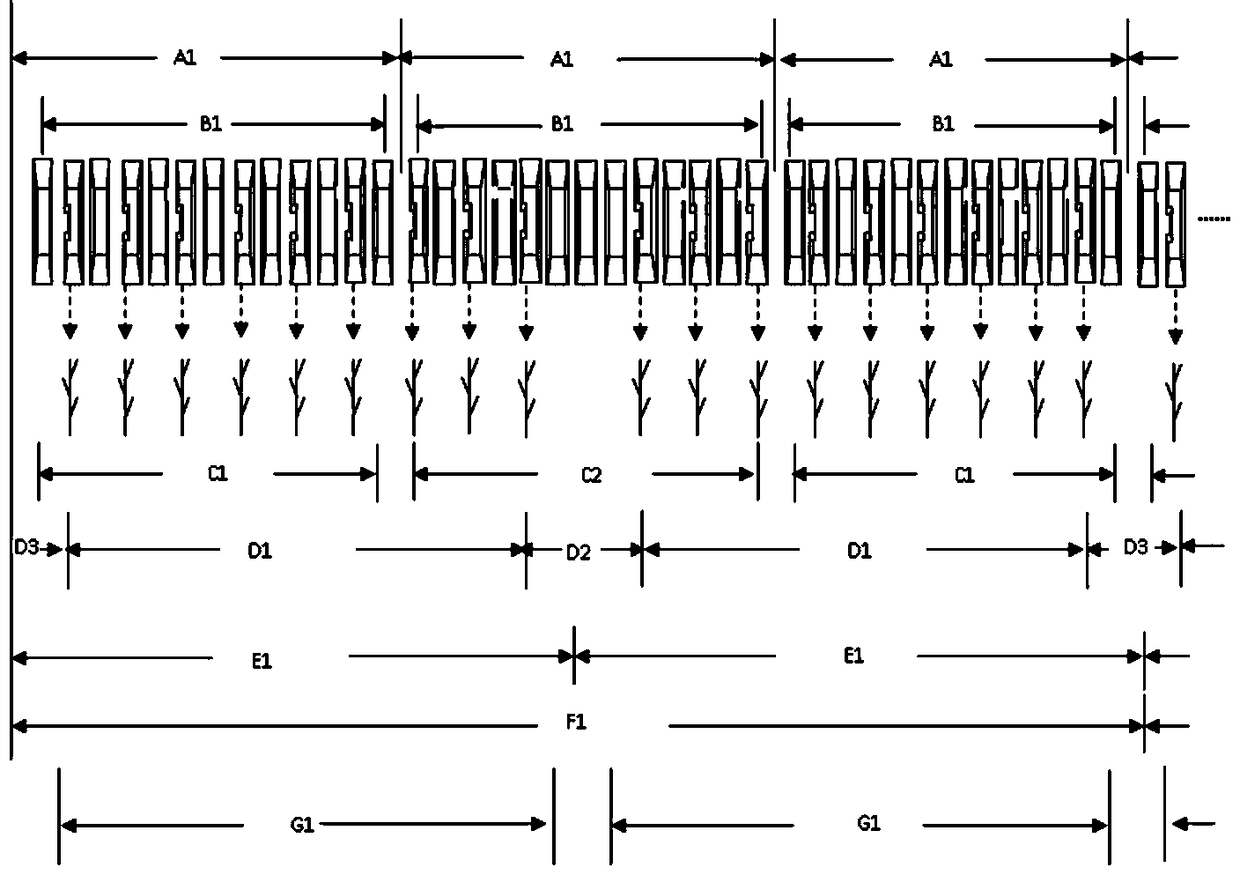

[0018] The wheat rotary tillage, sowing and suppression integrated machine is an improved type (improved by local agricultural machinery) produced by the Daqu Fertilization and Seeder Factory in Yanhu District, Yuncheng City, Shanxi Province. The model is SGTN-200Z14A7". Wheat rotary tillage, seeding and suppression all-in-one machine with a width of 200cm (A1), a seeding width of 180cm (B1) (the distance between side rows and side rows), and planting 13 rows.

[0019] (1) Divide the planting point: Make a mark every 200cm...

Embodiment 2

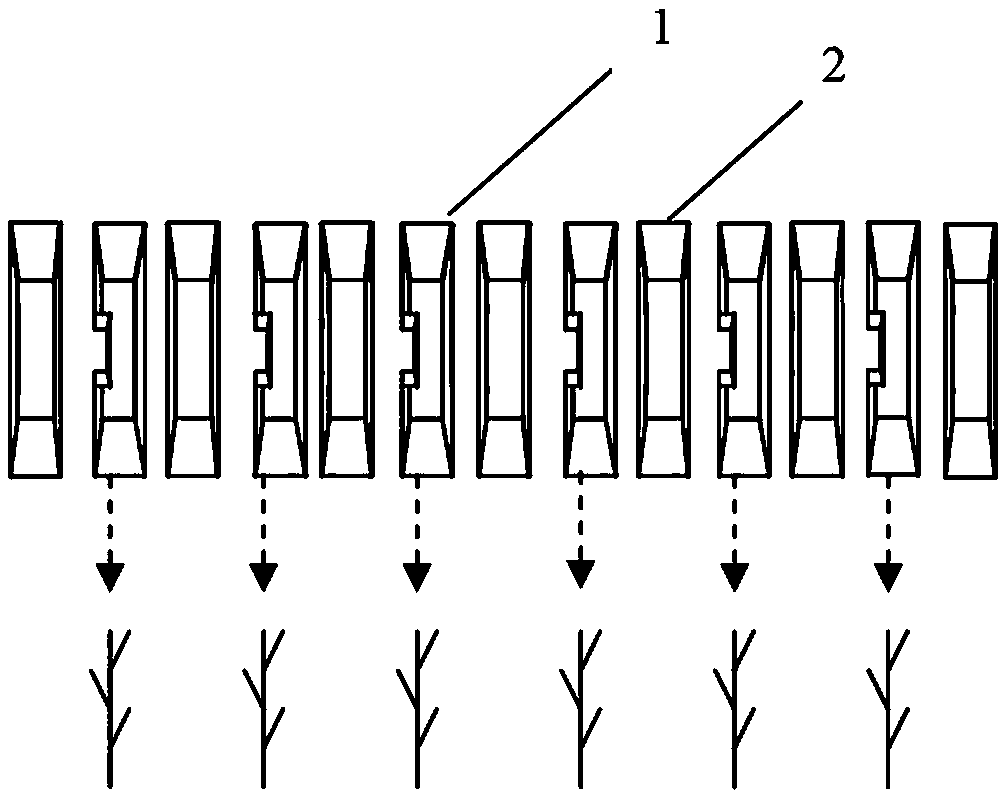

[0025] According to the inventive method, adopt different types of millet special-purpose seeders to sow, determine the number of suitable seeders, form the planting belt of about 245cm, leave the interval belt of 50-60cm, can be combined with the wheat combine harvester (header width 260cm ) matching harvesting, which can effectively solve the yield loss caused by the entanglement of grain ears during the harvesting process of the harvester.

[0026]Applied sowing operation width is about 30 (SG-1), 50 (Shengfeng / 2BG-3 sowing operation width 48cm), 60 (LL-BZJ-3), 120 (SL STJB), 125 (2BJ-6) 8, 5, 4, 2, 2 machines are used to sow 8, 5, 4, 2, 2 machines respectively to form planting belts of 240, 250, 240, 240, 250 cm respectively, leaving 50-60 cm between the planting belts The interval belts form 295, 305, 295, 295, 305 planting strips, each planting strip is a planting unit, and each planting unit can be harvested by a wheat combine harvester (header width about 260cm) . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com