Raw material sundry hardware screening device for feeding work of film blowing machine

A technology of screening device and film blowing machine, which is applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., and can solve problems such as affecting the operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

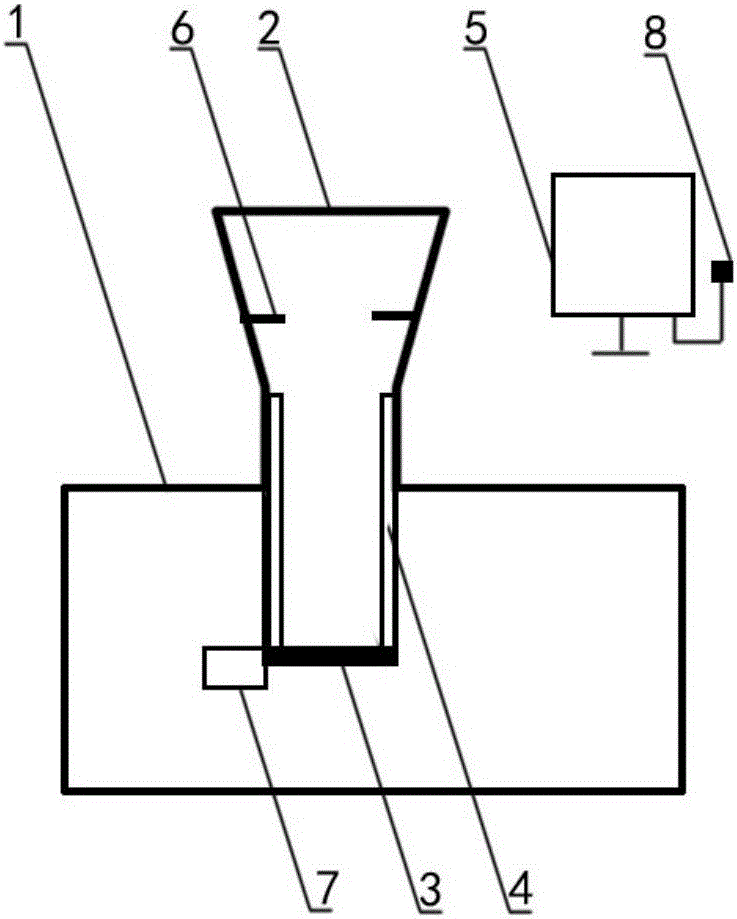

[0012] Embodiment: as shown in the accompanying drawing. The hardware screening device for raw materials and sundries in the feeding operation of the film blowing machine includes a body (1), on which a feeding storage frame (2), an induction switch (3), a magnetic module (4), and a management module are set. (5), during operation, the raw material is placed in the feeding storage frame (2), the induction switch (3) controls its switch state, the magnetic absorption module (4) screens the metal debris in the raw material, and the management module (5) according to the specific situation Process aggregated information.

[0013] The hardware screening device for raw materials and sundries in the film blowing machine feeding operation is equipped with a stirring and vibrating module (6) on the feeding storage frame (2) to vibrate and stir the raw materials so that the metal sundries are fully screened.

[0014] The film blowing machine feeding operation raw material sundries har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com