Axle assembly for plant-protection pesticide and fertilizer spraying machine

A component and fertilizer spraying technology, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problem of affecting the normal running of the plant protection fertilizer sprayer, the low height of the plant protection sprayer chassis, and damage to the plant protection sprayer Fertilizer and other problems, to achieve the effect of less collapse, reduce rut marks, and increase the height of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

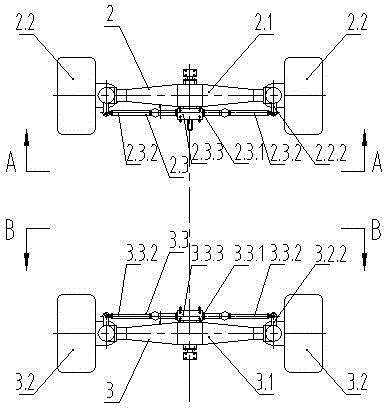

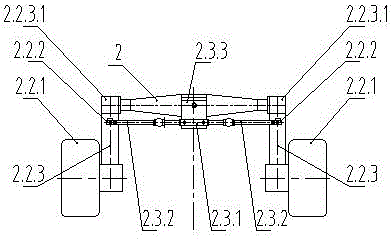

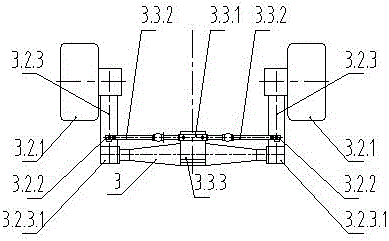

[0017] The axle assembly of the plant protection pesticide spraying machine shown in the accompanying drawing comprises a front axle 2 and a rear axle 3; Component 2.2 is set on both sides of the front beam 2.1, including front wheel 2.2.1, front wheel steering lever 2.2.2, support component I2.2.3; front wheel steering drive device 2.3 includes power cylinder I2.3.1, steering tie rod I2 .3.2. Support base I2.3.3, support base I2.3.3 is fixedly connected to the middle of front beam 2.1, power cylinder I2.3.1 is placed horizontally, fixedly connected to support base I2.3.3, one end of steering tie rod I2.3.2 is connected The rod end of the piston rod protruding from the cylinder I 2.3.1 is connected, and the other end is hinged with the front wheel steering lever 2.2.2; the support assembly I 2.2.3 includes the front crossbeam end shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com