Single-column house

A single-column and house technology, applied in the field of single-column houses, can solve problems such as inability to realize rotation, single structure, and large floor space, and achieve the effects of improving traffic congestion, changing structures, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

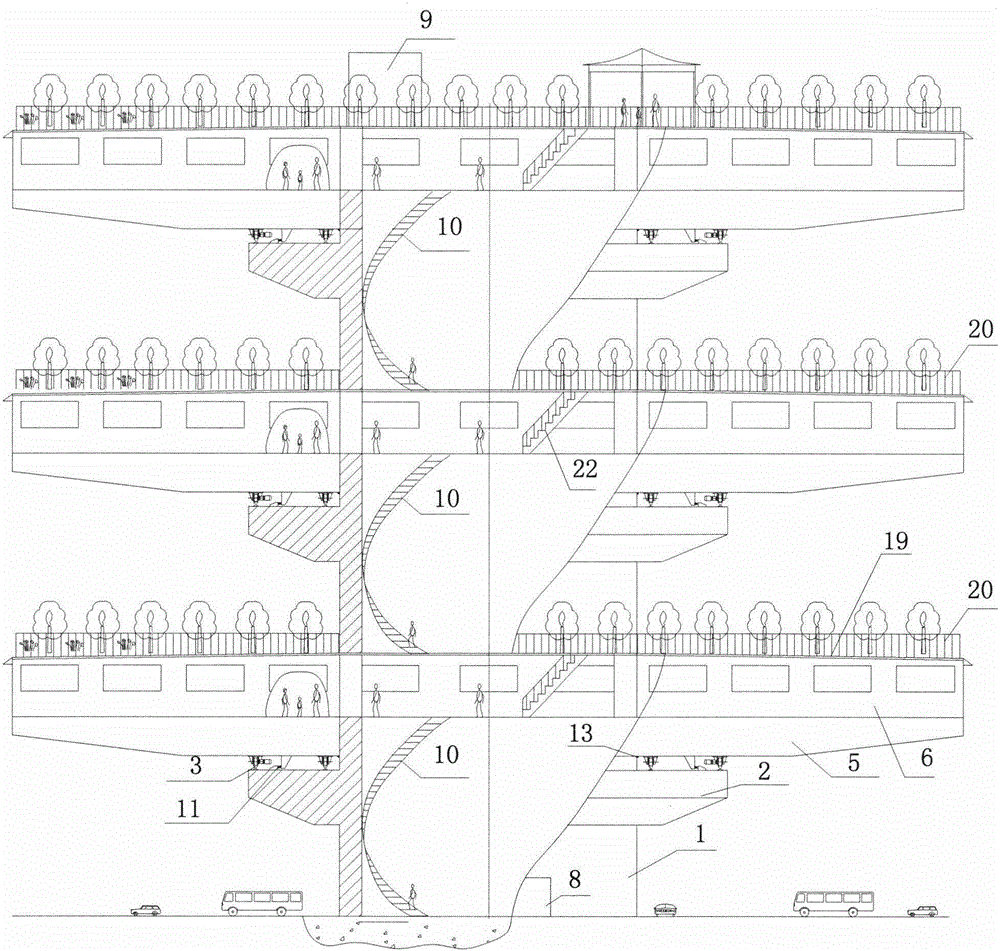

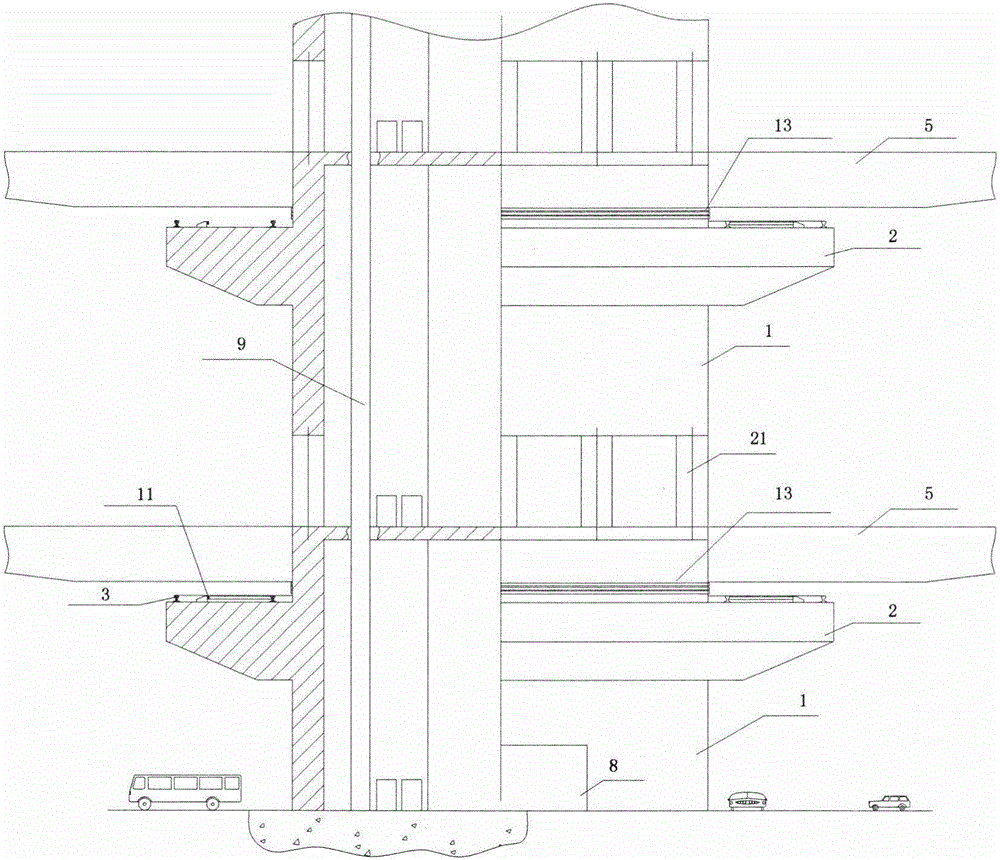

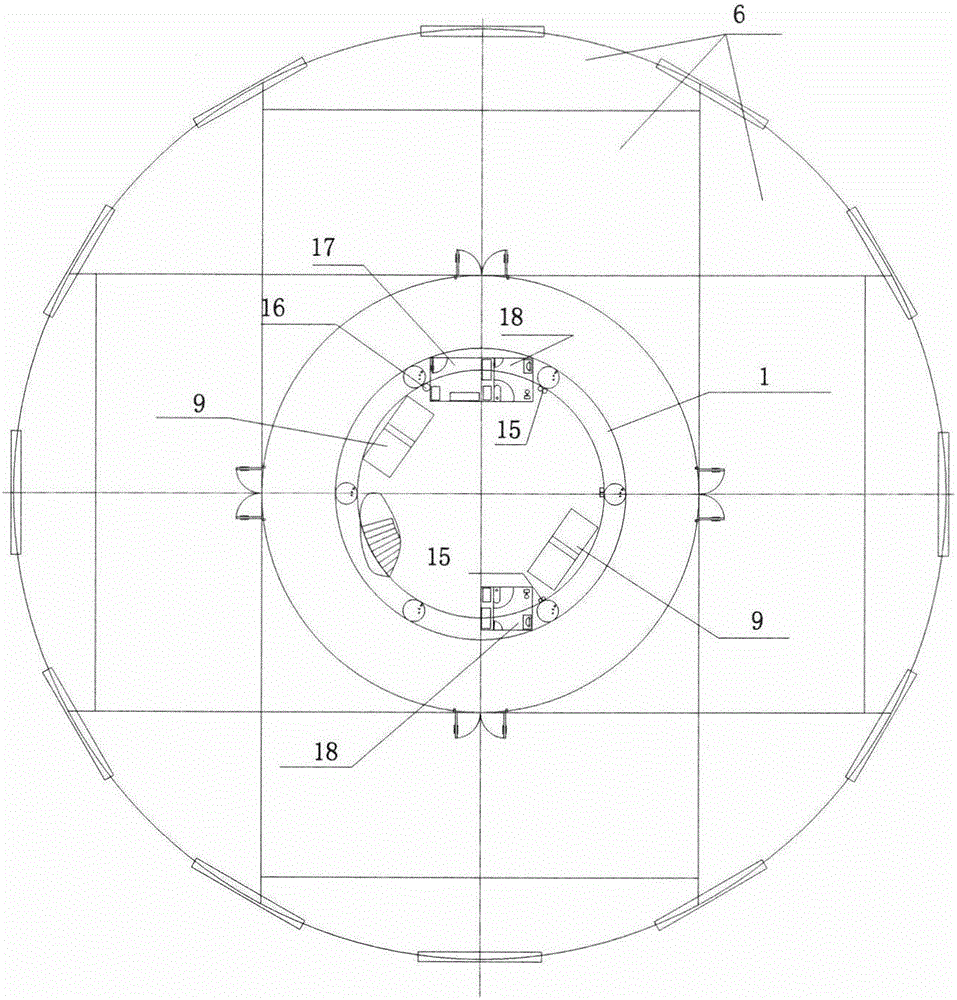

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] refer to Figure 1 to Figure 8 , a single-column house, including a hollow independent support column 1, a load-bearing boss 2, a turntable 5 and a house floor unit 6, the hollow independent support column 1 is circular, and the outer walls of the hollow independent support column 1 are layered sequentially A load-bearing boss 2 is provided, and two inner and outer circles of load-bearing rails 3 are arranged on each load-bearing boss 2, and a load-bearing wheel 4 is installed on the load-bearing track 3, and the load-bearing wheel 4 is located at the bottom of the turntable 5, and the turntable 5 is arranged The building floor unit 6, the bearing wheel 4 is connected with the driving device 7 for driving the turntable to rotate;

[0030] There is a door 8 at the junction of the hollow independent support column 1 and the ground, and the interior of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com