Outdoor tent and manufacturing technology

A manufacturing process and technology for tents, applied in tents/canopies, construction, textiles and papermaking, etc., can solve the problems of poor waterproof performance and narrow sense of space, and achieve the effect of enhancing waterproof performance, reducing discomfort, and increasing waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A manufacturing process of an outdoor tent includes the following steps:

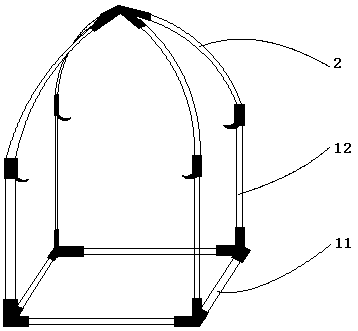

[0055] Preparation of S1 bracket: prepare straight rod I 11, straight rod II 12 and curved rod 2 according to the requirements of the drawings;

[0056] Preparation of S2 sleeve head: prepare three-head sleeve mouth, four-head sleeve mouth and two-end sleeve mouth with hooks according to the drawing requirements;

[0057] The production of S3 base cloth 5: Cut the asbestos cloth and moisture-proof board according to the drawings, stitch the inner and outer cloths of the base cloth 5 along the circumference of the asbestos cloth, and evenly coat the waterproof coating on the outer cloth;

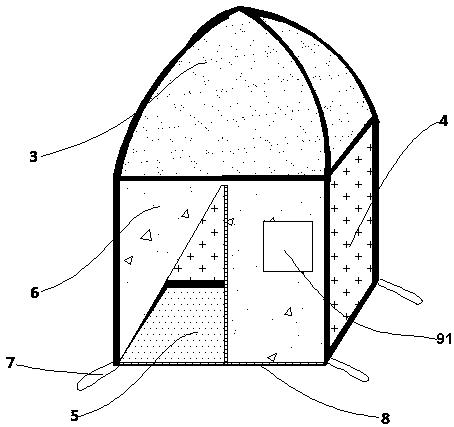

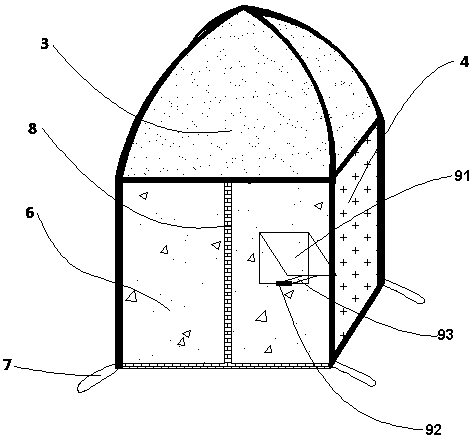

[0058] S4 Fabrication of top cloth 3 and side cloth 4: According to the drawings, stitch the inner and outer cloths of the top cloth 3 and side cloth 4, and coat the outer cloth with a waterproof coating evenly;

[0059] S5 door curtain fabric 6 production: according to the drawing, stitch the inner fabric and outer fabri...

Embodiment 2

[0067] A manufacturing process of an outdoor tent includes the following steps:

[0068] Preparation of S1 bracket: prepare straight rod I 11, straight rod II 12 and curved rod 2 according to the requirements of the drawings;

[0069] Preparation of S2 sleeve head: prepare three-head sleeve mouth, four-head sleeve mouth and two-end sleeve mouth with hooks according to the drawing requirements;

[0070] The production of S3 base cloth 5: Cut the asbestos cloth and moisture-proof board according to the drawings, stitch the inner and outer cloths of the base cloth 5 along the circumference of the asbestos cloth, and evenly coat the waterproof coating on the outer cloth;

[0071] S4 Fabrication of top cloth 3 and side cloth 4: According to the drawings, stitch the inner and outer cloths of the top cloth 3 and side cloth 4, and coat the outer cloth with a waterproof coating evenly;

[0072] S5 door curtain fabric 6 production: according to the drawing, stitch the inner fabric and outer fabri...

Embodiment 3

[0080] A manufacturing process of an outdoor tent includes the following steps:

[0081] Preparation of S1 bracket: prepare straight rod I 11, straight rod II 12 and curved rod 2 according to the requirements of the drawings;

[0082] Preparation of S2 sleeve head: prepare three-head sleeve mouth, four-head sleeve mouth and two-end sleeve mouth with hooks according to the drawing requirements;

[0083] The production of S3 base cloth 5: Cut the asbestos cloth and moisture-proof board according to the drawings, stitch the inner and outer cloths of the base cloth 5 along the circumference of the asbestos cloth, and evenly coat the waterproof coating on the outer cloth;

[0084] S4 Fabrication of top cloth 3 and side cloth 4: According to the drawings, stitch the inner and outer cloths of the top cloth 3 and side cloth 4, and coat the outer cloth with a waterproof coating evenly;

[0085] S5 door curtain fabric 6 production: according to the drawing, stitch the inner fabric and outer fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com