Underground combustion convection heating method

A convective heating and burner technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of large heat loss, high cost, low utilization rate, etc., and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Underground Open Combustion Convection Heating Method

[0029] Underground open combustion convection heating method, which includes:

[0030] 1) Inject high-pressure air into the casing of the heater well;

[0031] 2) The gas and the combustion-supporting gas are respectively sent into the well casing through the pipeline, at the mining area, mixed and burned in the burner;

[0032] 3) The heat generated by the combustion of the burner heats the high-pressure air injected into the well casing, and mixes with the exhaust gas and air generated by the combustion to form a mixed heating medium;

[0033] 4) The kerogen in the heavy oil or oil shale deposit is pyrolyzed to form oil and gas, and the mixed heating medium is discharged from the oil production well;

[0034] In the step 1), the flame retardant fluid is injected through the pipeline under the burner;

[0035] The flame retardant fluid is CO 2 gas, steam or water.

Embodiment 2

[0036] Embodiment 2 Underground open combustion convection heating device

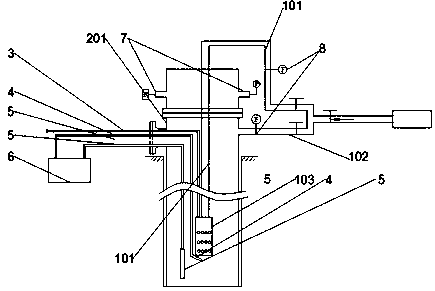

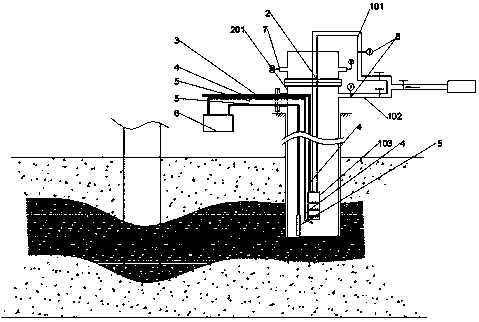

[0037] Underground open combustion convection heating device, including: well casing air injection pipe 102, combustion-supporting gas delivery pipe 101, gas delivery pipe 3, ignition device 4, burner 103;

[0038] The combustion-supporting gas delivery pipe 101 and the gas delivery pipe 3 are connected to the burner 103, and the burner 103 is arranged in the well casing 201, at the mining area;

[0039] The underground open combustion convection heating device further includes: a temperature monitoring device 5 , an air pressure monitoring device 7 , a flow monitoring device 8 , and a central controller 6 .

Embodiment 3

[0040] Embodiment 3 Underground open combustion convection heating device

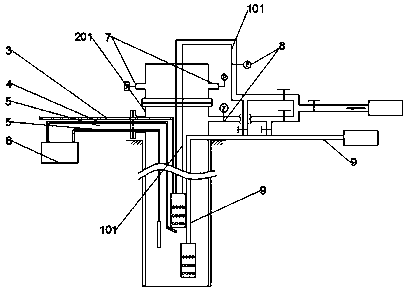

[0041] Underground open combustion convection heating device, including: well casing air injection pipe 102, combustion-supporting gas delivery pipe 101, gas delivery pipe 3, ignition device 4, burner 103;

[0042] The combustion-supporting gas delivery pipe 101 and the gas delivery pipe 3 are connected to the burner 103, and the burner 103 is arranged in the well casing 201, at the mining area;

[0043] The underground open combustion convection heating device also includes: a temperature monitoring device 5, an air pressure monitoring device 7, a flow monitoring device 8, and a central controller 6;

[0044] The underground open combustion convection heating device further includes: a flame retardant fluid delivery pipe 9, the outlet of which is located at or below the burner 103;

[0045] The upper section of the flame retardant fluid delivery pipe 9 communicates with the combustion-supporting gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com