A soil sample mold making and demoulding device

A demoulding device and soil sample technology, which is applied in the measurement device, the preparation and sampling of test samples, etc., can solve the problems of low working efficiency of the three-part mold, affecting the accuracy of soil sample experimental data, large errors, etc. Safe and reliable, functional diversification, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

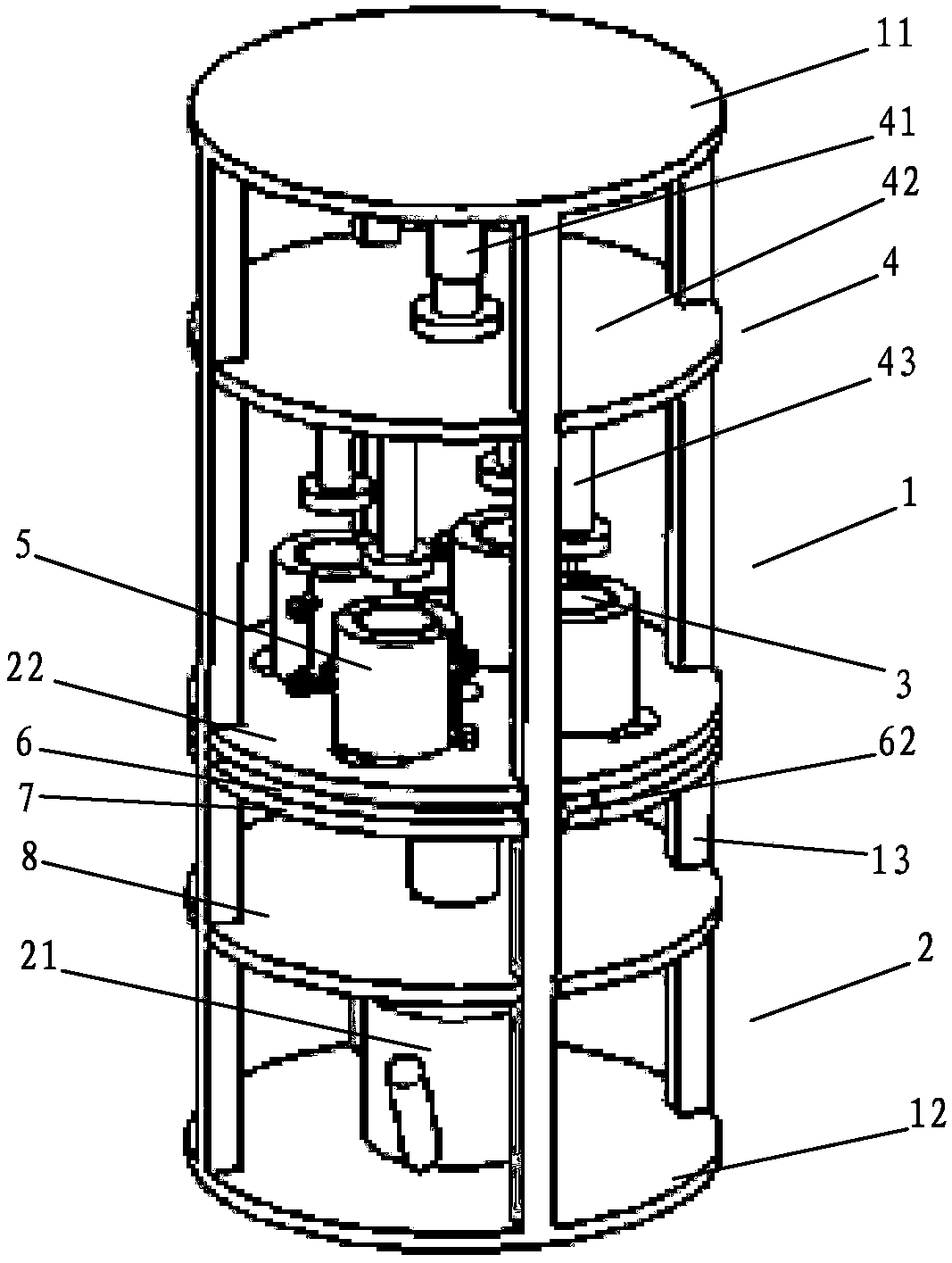

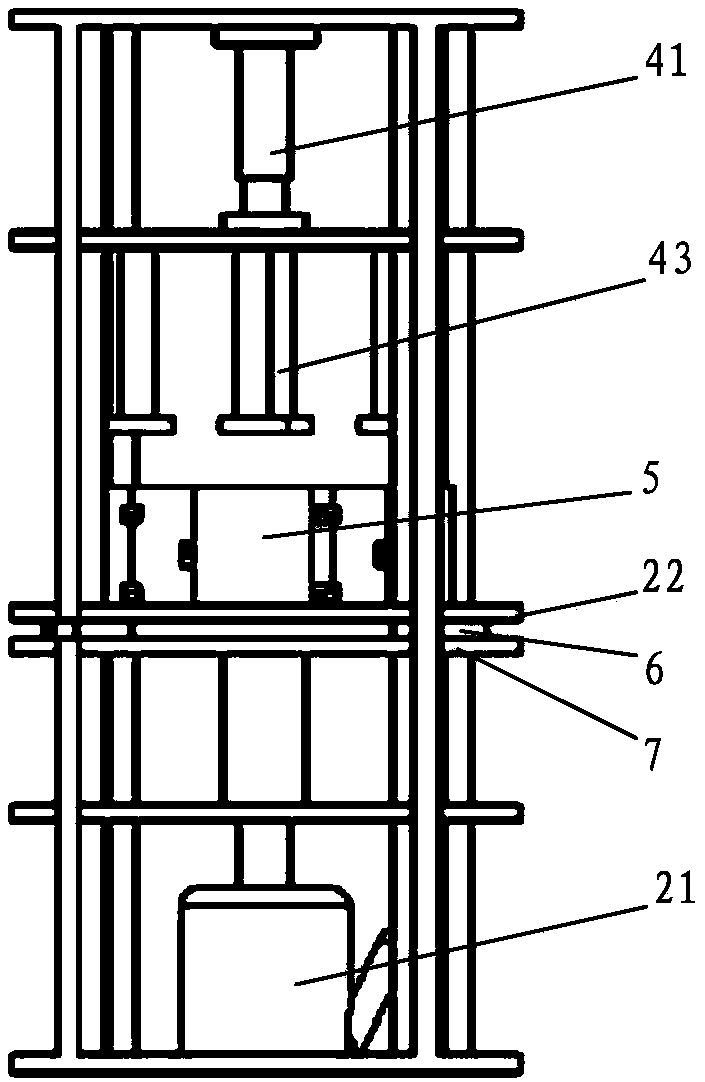

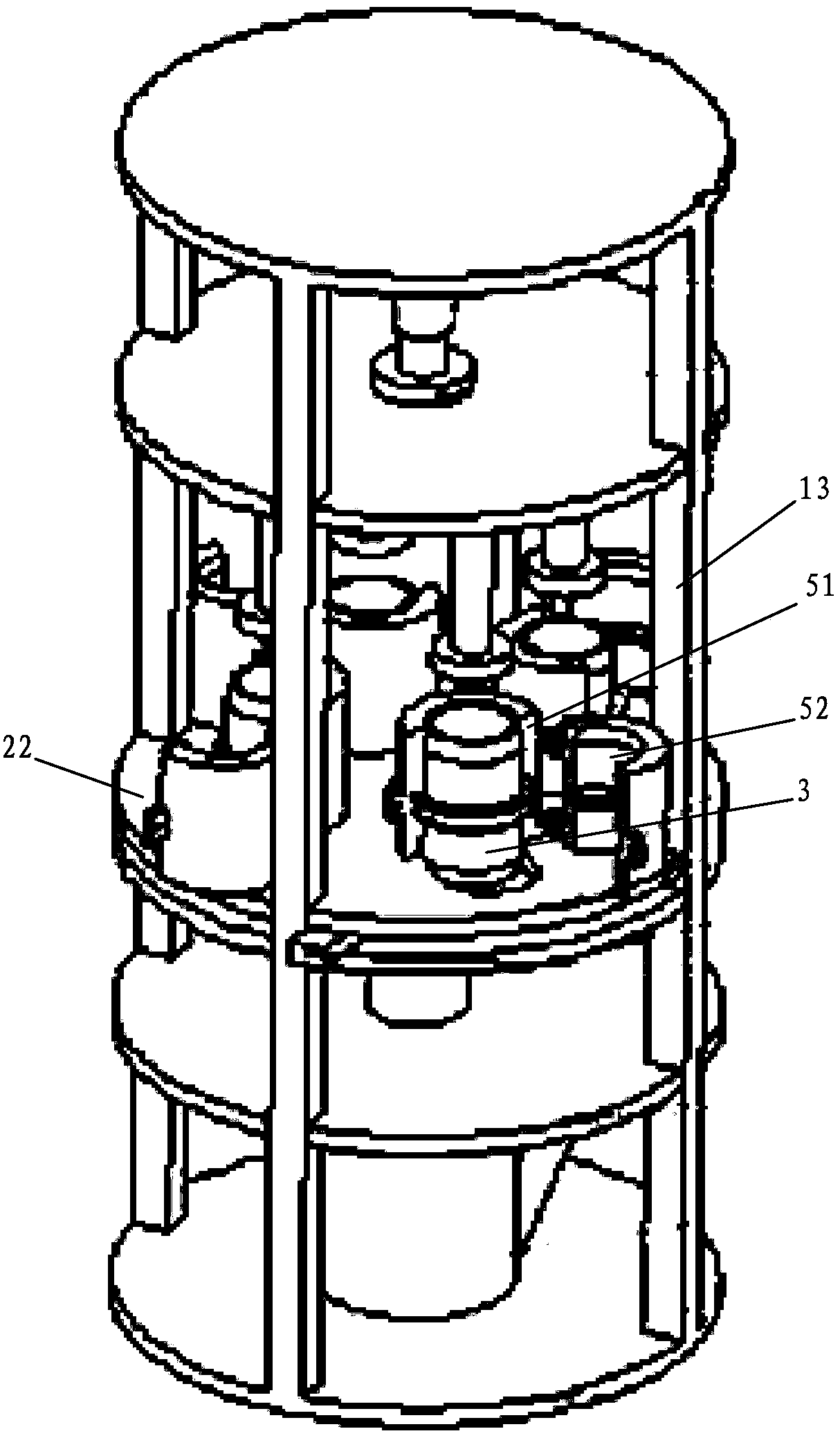

[0025] refer to figure 1 with figure 2 , the present embodiment relates to a soil sample molding and demoulding device, including a bracket 1 and an adjustment mechanism 2 arranged on the bracket 1, a mold 3 and a pressing mechanism 4, and the adjustment mechanism 2 is slidably installed on the lower part of the bracket 1 , the pressing mechanism 4 is slidably installed on the upper part of the bracket 1, the mold 3 is fixedly installed on the adjusting mechanism 2, and is arranged between the adjusting mechanism 2 and the pressing mechanism 4, and the pressing mechanism 4 The pressing mechanism 4 presses or releases the mold 3 . When working, the height of the mold 3 can be adjusted through the adjustment mechanism 2, so that people of different heights can fill the loose soil into the mold 3. After filling the loose soil into the mold 3, the pressing mechanism 4 presses down toward the mold 3. , so that the loose soil is compacted into a soil sample, which solves the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com