Contour-parallel offset tool path linking method of double-ring-shaped sections

A connection method and cross-section technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve problems such as non-compliant processing, achieve the effects of avoiding frequent tool jumps, smooth processing, and improving surface processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

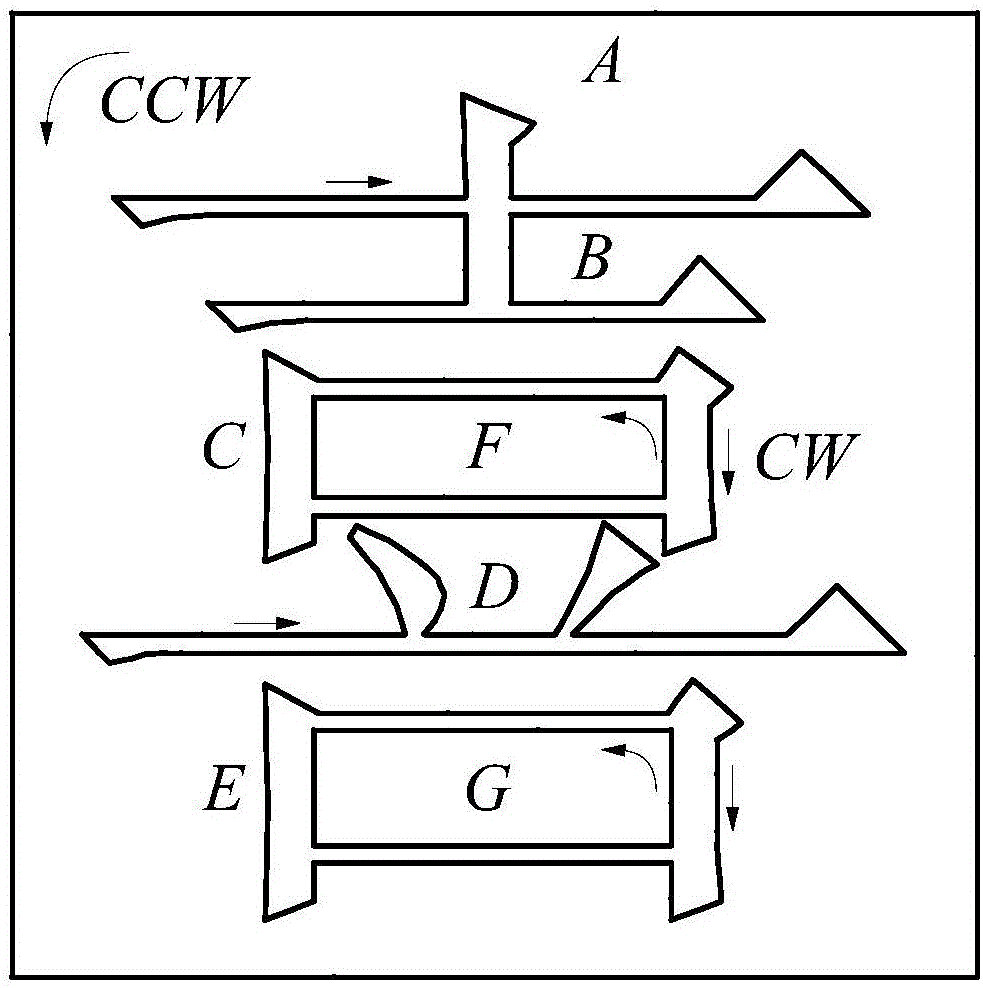

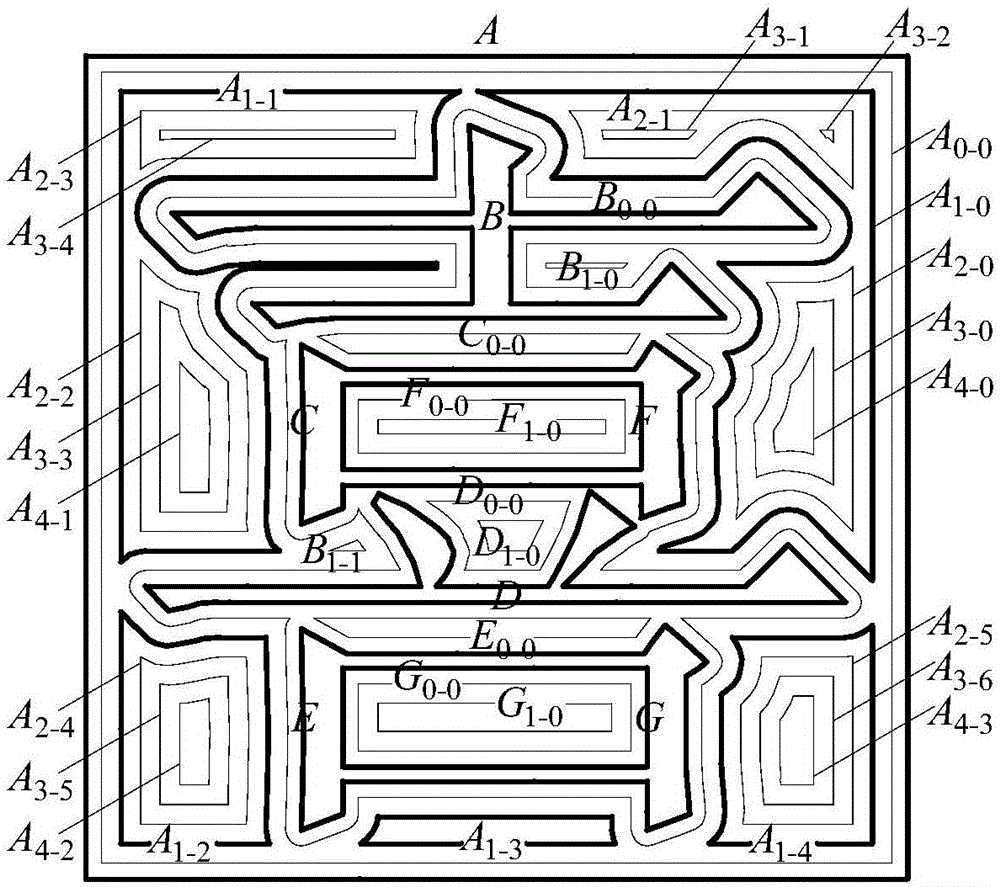

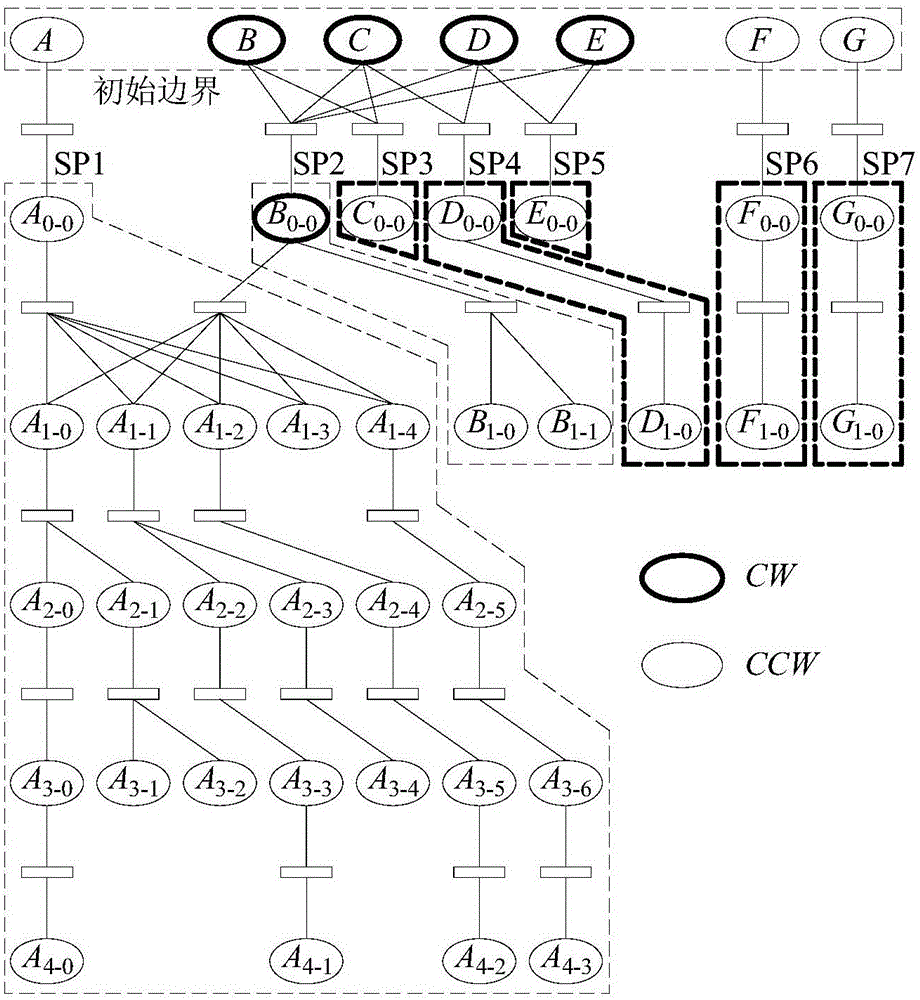

Method used

Image

Examples

Embodiment 2

[0078] Figure 7 Given the case with multiple CW loops, p 1 is the starting point of processing, starting from p 1 ~p 8 Complete the machining of the CCW I-ring, as shown by the thin solid line in the figure. Since there is no CCW II-type ring, the next step is to start processing the CW-type ring, that is, the dotted line in the figure, and the processing route is p 8 ~p 15 , the thick dotted line in the figure is the jump route for lifting the knife. It can be seen from the figure that the CCW ring is processed from the inside to the outside, while the CW ring is processed from the outside to the inside, and the direction along the ring is also different.

Embodiment 3

[0080] Figure 8 Given the case where two CW parent rings are contained by the same CW child ring, p 1 is the starting point of processing, starting from p 1 ~p 12 Complete the machining of the CCW I-ring, as shown by the thin solid line in the figure. Since there is no CCW II-type ring, the next step is to process the CW-type ring, that is, the dotted line in the figure, first from p 12 point jump knife to p 13 point, slowly cut into p 14 point, then machine clockwise around the ring, back to p 14 After point, cut into p 15 point, process p clockwise 15 Point the ring, return to p 15 After point, cut into p 16 point, process p clockwise 16 Point the ring, return to p 16 After pointing, jump knife to p 17 point, process p clockwise 17 Point the ring, return to p 17 After point, cut into p 18 point, process p clockwise 18 Point the ring, return to p 18 After point, cut into p 19 point, process p clockwise 19 Point the ring, return to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com