All-directional pneumatic film-and-weed-separation plastic-film-residue recycling machine

A pneumatic membrane, all-round technology, applied in the direction of collectors, agricultural machinery and tools, shovels, etc., can solve the problems of incomplete recycling of residual film, inability to separate residual film from weeds, etc., and achieve easy replacement, labor saving, and leakage The effect of high pick-up rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

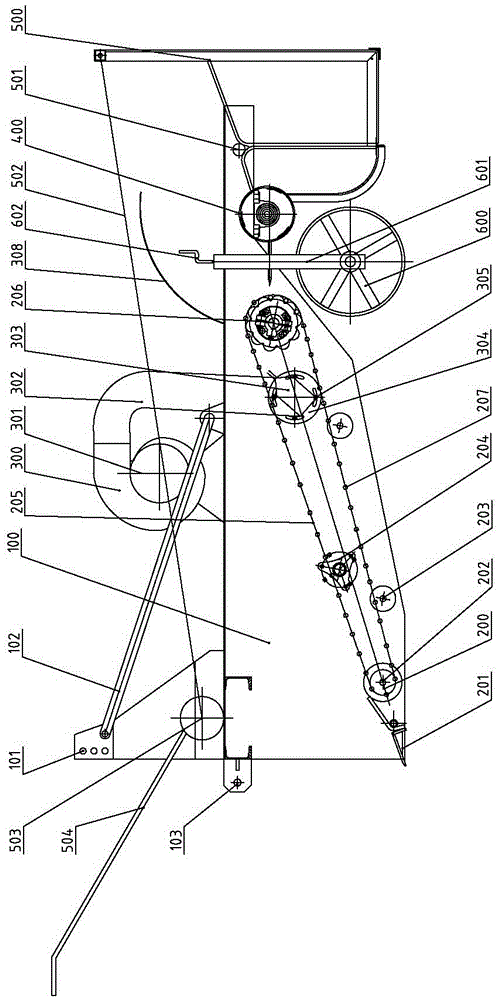

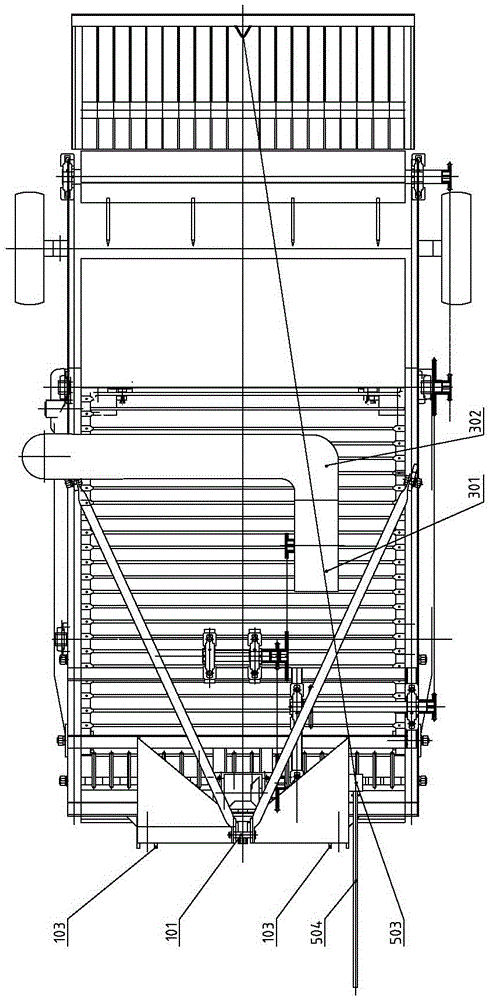

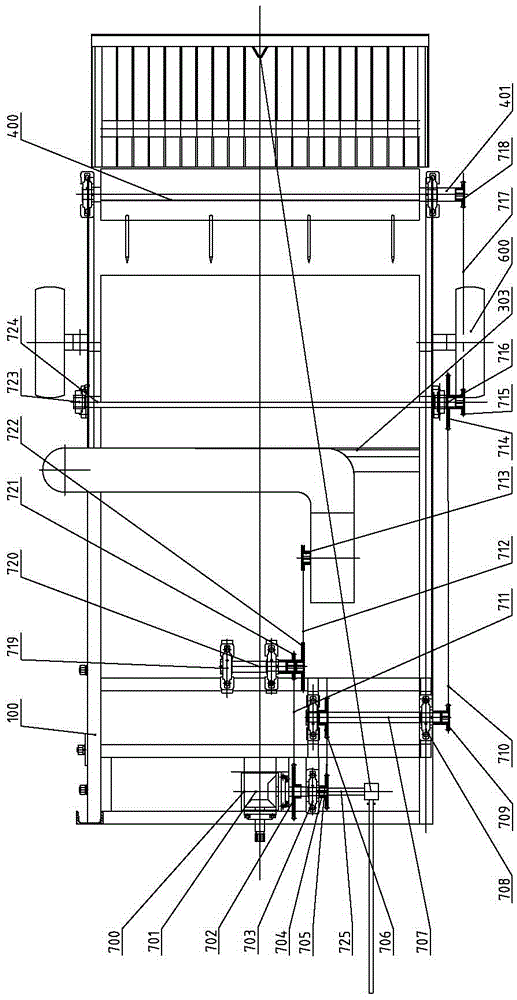

[0022] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a kind of all-round pneumatic film miscellaneous separation and residual film recovery machine of the present invention includes a frame 100, a shaking soil conveying system 200, a wind power system 300, a film rolling roller 400, The miscellaneous basket 500, the depth gauge wheel 600 and the transmission system 700.

[0023] An upper suspension hole 101 is arranged on the front upper part of the frame 100, and two lower suspension holes 103 are symmetrically arranged below the upper suspension hole 101, forming a suspension device. Next to the upper suspension hole 101 of the frame 100 and the rear of the frame 100, a pull bar 102 is fixed, and the frame is strengthened.

[0024] The soil shaking conveying system 200 is arranged at the front and bottom of the frame 100 . The function of the shaking soil conveying system 200 is to vibrate the soil while conveying to the rear and upper side. Specifically, a shoveling plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com