Parallel flexible cable suspension simulation system and parallel flexible cable suspension simulation method employing same

A simulation system and flexible cable technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as poor measurement accuracy, inability to automatically change the center of gravity of the suspension pan, and inability to realize suspension simulation, so as to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

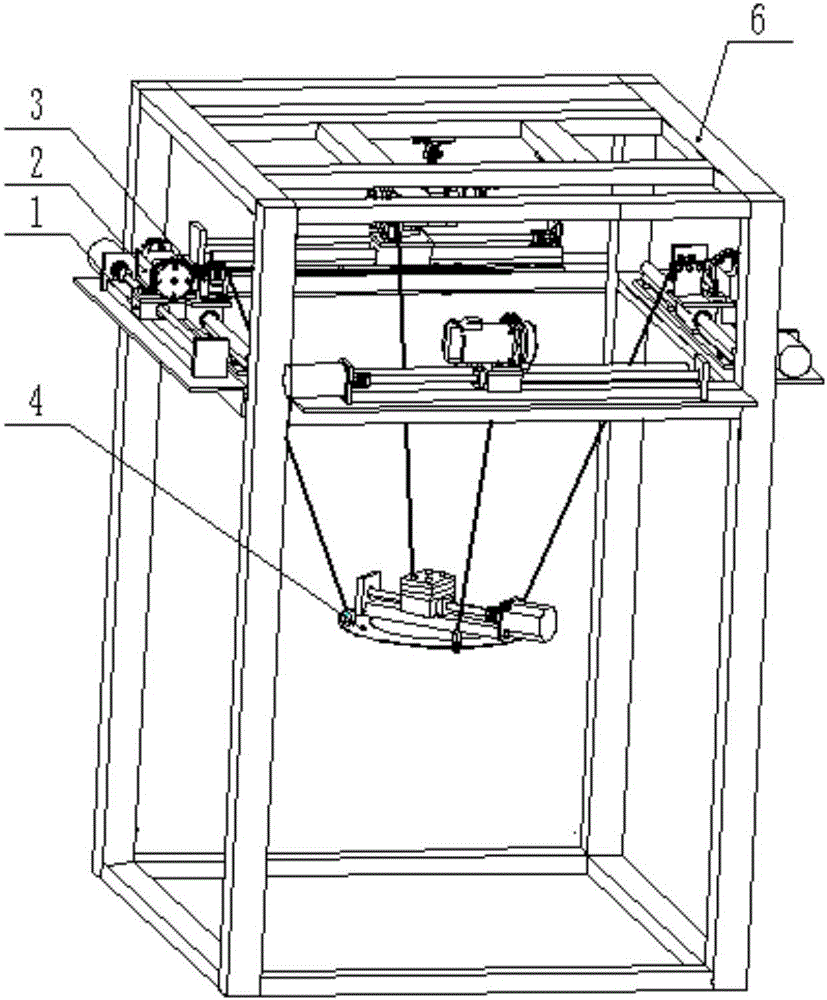

[0029] Embodiment 1, as figure 1 As shown, the parallel flexible cable suspension simulation system of the present invention is mainly composed of a frame 6, a suspension plate 4 arranged in the frame 6, and four movable platforms 1 arranged symmetrically in a square center are arranged around the upper part of the frame 6. Each movable platform 1 is provided with a drive assembly 2 that is respectively connected to the cables of the hanging pan 4, and one side of each drive assembly 2 is provided with a tension measuring assembly 3 that measures the tension of the cables; each drive assembly 2 The reels are provided with flexible cables connected to the four lifting lugs of the hanging pan 4, and each flexible cable is respectively connected to a hanging pan 4 built in the frame 6 through the guide pulley 3-2 of the tension measuring assembly 3. The connection with the hanging pan 4 is in an angle connection state.

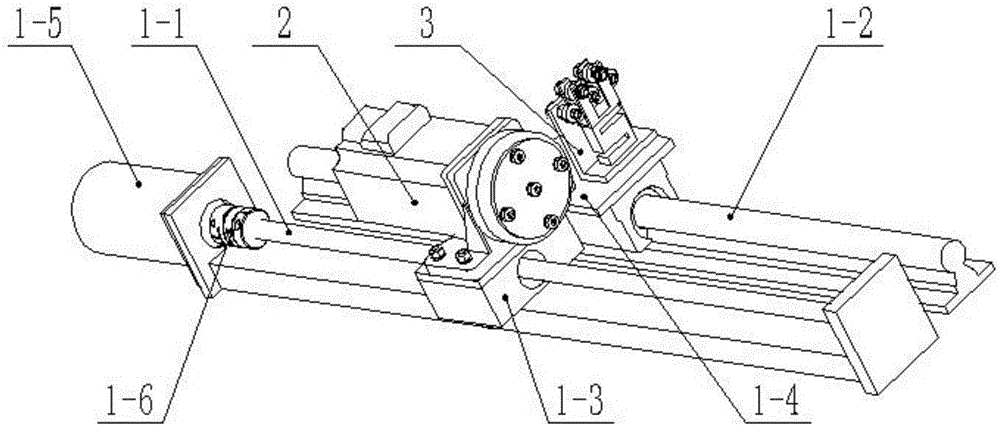

[0030] figure 2 As shown, the movable platform 1 include...

Embodiment 2

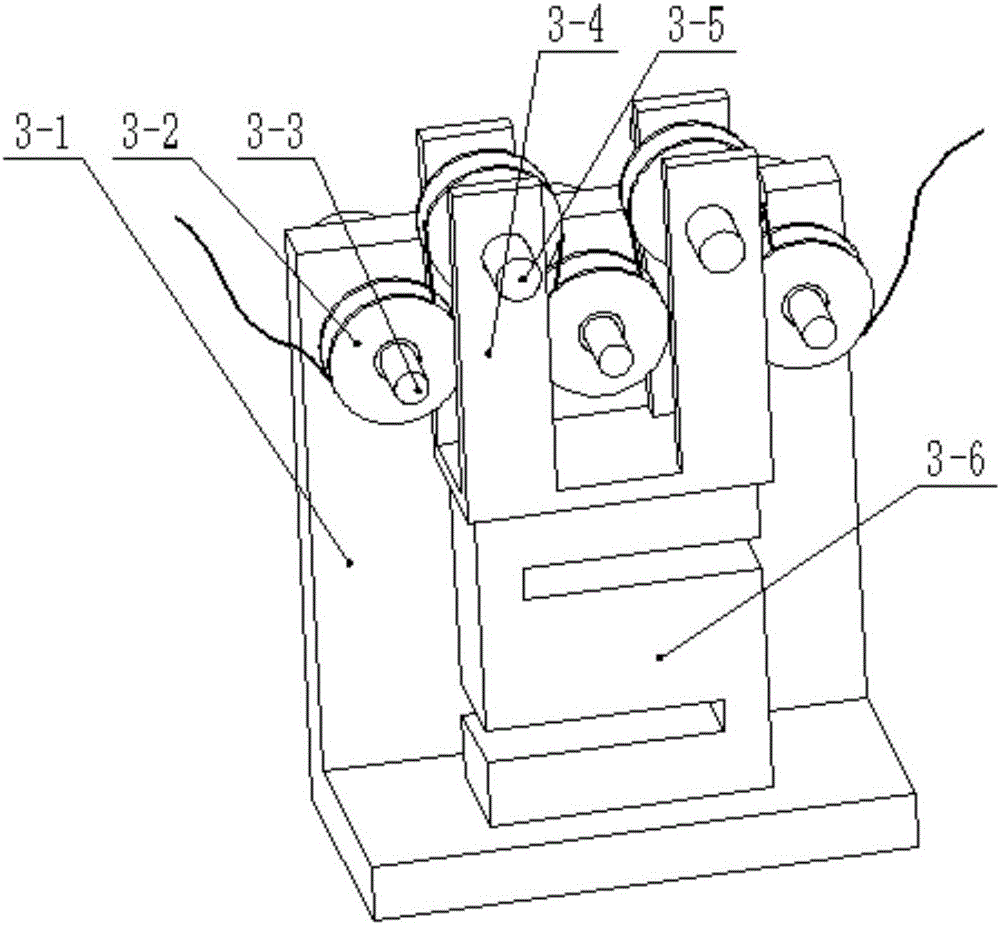

[0034] Embodiment 2, as Figure 7As shown, it is basically the same as Example 1, and the same part is omitted. The difference is that: the top of the frame 6 is provided with a guide assembly 5, and the flexible cables connected to the four lifting lugs of the suspension pan 4 provided on the reel of each drive assembly 2 pass through the guide pulley of the tension measurement assembly 3 After 3-2, go around the guide assembly 5 that is located at the inner top of the frame 6, and then be connected to a hanging pan 4 built into the frame 6, and the connection between the cable and the hanging pan 4 is a vertical connection state. Guided by the guide pulley 3-2 on the tension measuring component 3, the tension of the cable is expanded to four times its size and acts on the tension and pressure sensor 3-6, and the signal is immediately transmitted to the control system of the upper computer for automatic leveling. After the control system analyzes the signal, the motor 2-1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com