tire inflator

A tire and air source technology, applied in the field of inflators, can solve the problems of lowering the accuracy of inflating, long gas path of the inflator, inconvenient inflating, etc., and achieve the effects of reducing work intensity, high economic advantages, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

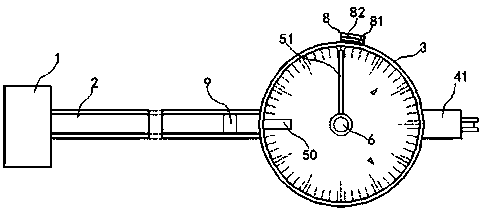

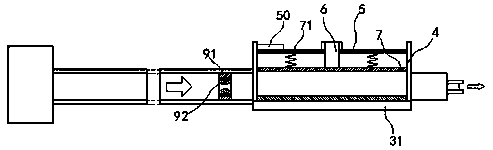

[0018] exist figure 1 , figure 2 In the shown embodiment, the tire inflator includes an air source 1, an air guide pipe 2 and a pressure gauge 3; the pressure gauge 3 includes a sealing cylinder 4, and an air inlet and an air outlet are provided at the bottom of the sealing cylinder 4 The nozzle 41; the air guide pipe 2 is connected to the air inlet and the air source 1; the top of the sealing cylinder 4 is fixed and sealed by the dial 5, and a rotating shaft 6 is installed vertically in the center of the dial 5, and the pressure scale is engraved on the dial 5, and marked at the same time Commonly used standard values;

[0019] The rotating shaft 6 is airtightly connected to the dial 5 through threads; a pointer 51 made of a permanent magnetic material is fixedly sleeved on the rotating shaft 6; a limit column 50 is set at the zero point of the dial 5;

[0020] In the inside of the sealing cylinder 4, above the air inlet and the outlet nozzle 41, a piston plate 7 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com