Automatic labeling machine

A labeling machine, automatic technology, used in labeling machines, labels, packaging, etc., can solve problems such as low efficiency and insufficient reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below.

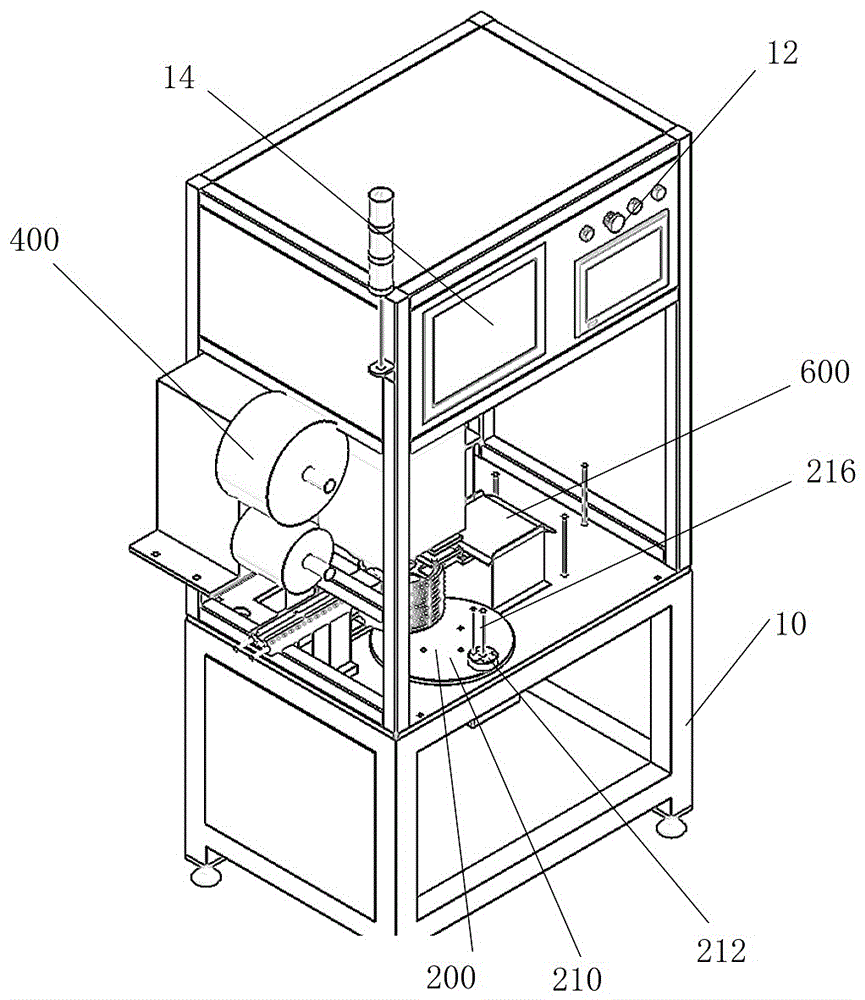

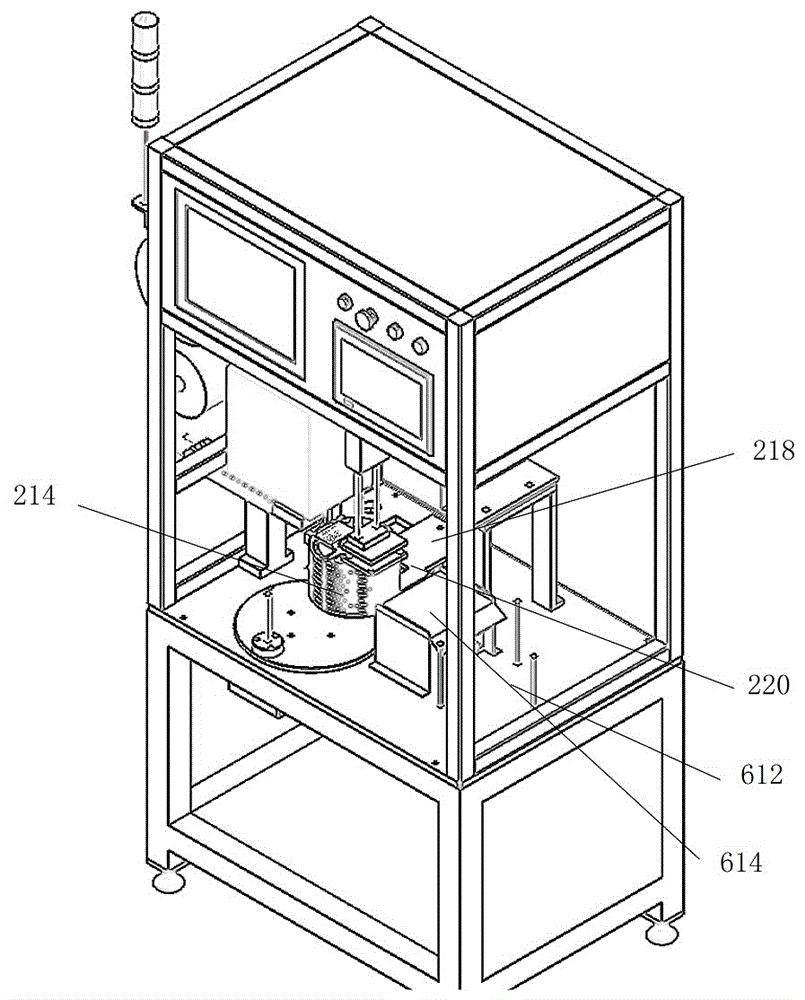

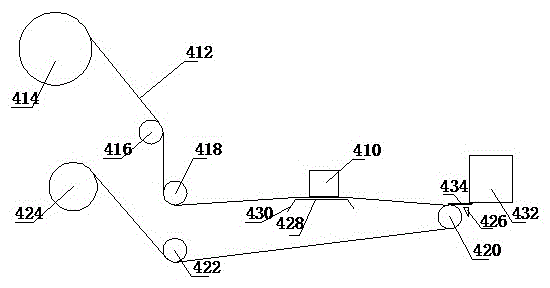

[0020] Such as Figure 1 to Figure 3 As shown, a kind of automatic labeling machine of the preferred embodiment of the present invention comprises frame 10, and frame 10 is provided with start switch 12 and control panel 14, and control panel 14 connects the control system that PLC controller or main computer form , the control panel 14 can be a touch display screen, and can control other components to act step by step or continuously. The frame 10 is also provided with a feeding mechanism 200 for conveying the tray; a label printing and peeling mechanism 400 for printing labels, peeling off the label and pasting the label on the tray; and a receiving mechanism 600 for collecting the labeled trays.

[0021] The feeding mechanism 200 includes an indexing plate 210 driven by a motor (not shown), and the indexing plate 210 is provided with at least two stations 212 that can place a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com