Scale Bucket Conveyor Belt Driven by Chain Plate Axis Chain

A shaft chain and conveyor belt technology, which is applied in the field of dry ash and slag material conveying, can solve the problems of poor conveyance of fine ash, easy ash leakage, easy falling off of bearing scales, etc. Guaranteed cleaning efficiency and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

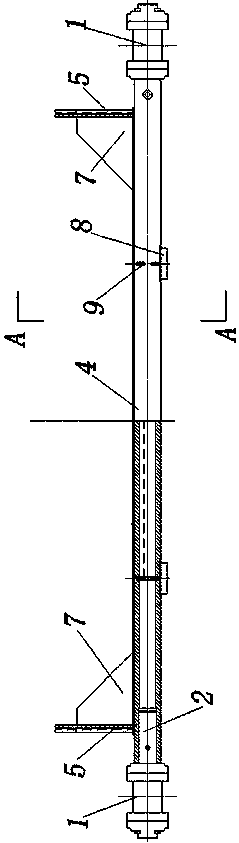

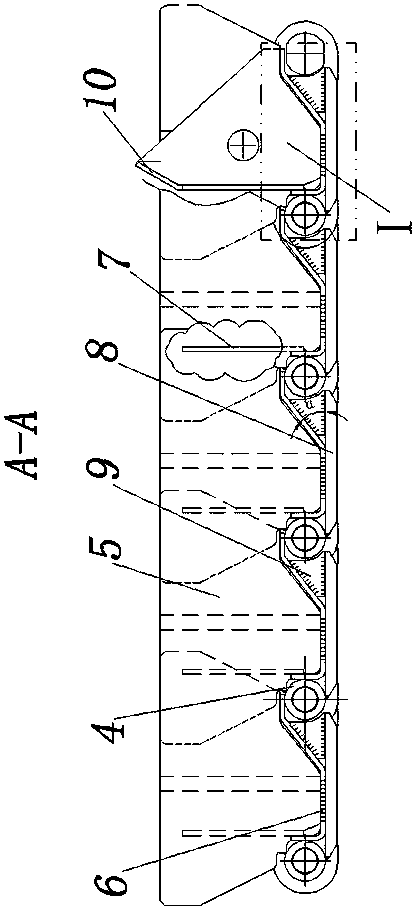

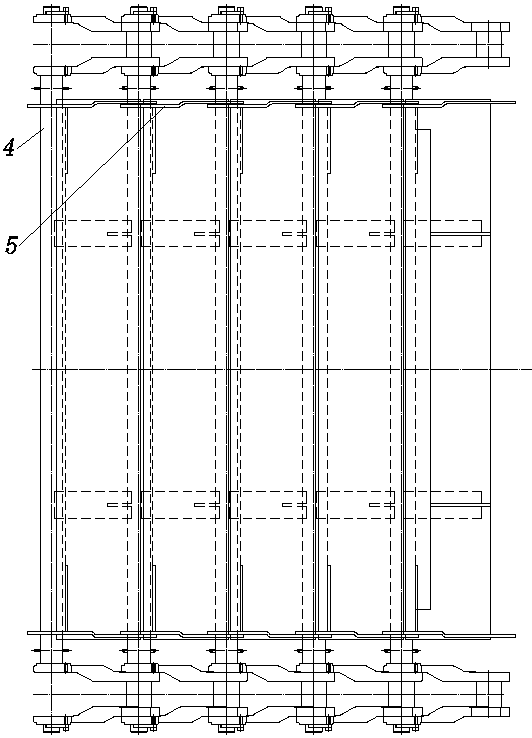

[0037] exist Figure 1 ~ Figure 4 Among them, the scale bucket conveyor belt dragged by the chain plate axis chain of the present invention includes two chain plate axis chains 1 installed on both sides, and is installed on the paired two sides of each chain link of the chain plate axis chain on both sides. Mandrel 2, scale buckets 3 that are installed on the mandrels on both sides of the pair and overlap each other; the scale buckets include central tubes 4 installed on the mandrels on both sides, and the retaining edges installed at both ends of the central tube Plate 5, the bucket groove 6 installed on the central pipe on the straight side, the stiffener plate 7 connected to the straight side of the bucket groove and the side plate of the retaining material, the wear-resistant plate 8 installed on the bottom of the bucket groove, installed on the scale bucket Positioning plate 9 between the hypotenuse and the wear plate.

[0038] The scale bucket conveyor belt dragged by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com