A kind of diamond powder particle size analysis sampling quantitative method

A diamond powder and particle size analysis technology, which is applied in particle size analysis, particle and sedimentation analysis, sampling, etc., can solve problems that affect the accuracy and stability of analysis results, troublesome sampling methods, and deviations in analysis results, etc., and achieve diamond particle size analysis. Standardized sampling methods, improved sample preparation efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

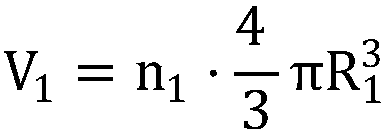

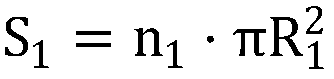

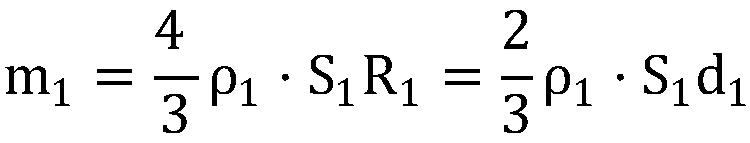

[0036] Take M8 / 12 diamond micropowder as the reference sample, and its average particle size is d 1 =(8+12) / 2=10μm, the laser particle size analyzer is used as the analysis instrument. After many tests, it is determined that the best sampling volume is 0.2±0.01g, and the test is relatively stable. Therefore, the best sampling volume for the reference sample is 0.2±0.01g.

[0037] Take three types of diamond powder, M2 / 4, M8 / 16, and M15 / 25 as the samples to be tested, and their average particle sizes are d. 2(M2 / 4) =(2+4) / 2=3μm, d 2(M8 / 16) =(8+16) / 2=12μm, d 2(M15 / 25) =(15+25) / 2=20μm, then according to the formula Calculate the optimal sampling volume of the three samples, as shown in Table 1. The three samples of diamond powder to be tested were prepared into suspensions for analysis by the laser particle size analyzer. All of them were successful at one time, and they all met the concentration requirements of the instrument analysis, and good test results were obtained, as shown ...

Embodiment 2

[0046] Take M8 / 12 diamond micropowder as the reference sample, and its average particle size is d 1 =(8+12) / 2=10μm, using the resistance method particle size analyzer as the analysis instrument, after many tests, it is determined that the best sampling amount is 0.1±0.001g, the test is relatively stable, so the best sampling amount for the reference sample It is 0.1±0.001g.

[0047] Take diamond powder M2 / 4, M8 / 16, M15 / 25 as the samples to be tested, and their average particle sizes are d respectively 2(M2 / 4) =(2+4) / 2=3μm, d 2(M8 / 16) =(8+16) / 2=12μm, d 2(M15 / 25) =(15+25) / 2=20μm, then according to the formula Calculate the optimal sampling volume of the three samples, as shown in Table 3. The three samples of diamond powder to be tested were prepared as suspensions for the analysis of the instrument resistance particle size analyzer. All of them were successful at one time and met the concentration requirements of the instrument analysis. The test results are shown in Table 3.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com