Method for measuring oxygen content in lanthanum, cerium metal or lanthanum-cerium alloy

A lanthanum-cerium alloy and a determination method technology, applied in the field of metal material gas analysis, can solve problems such as pollution interference, and achieve the effects of easy control, high test accuracy, and inhibition of volatilization pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

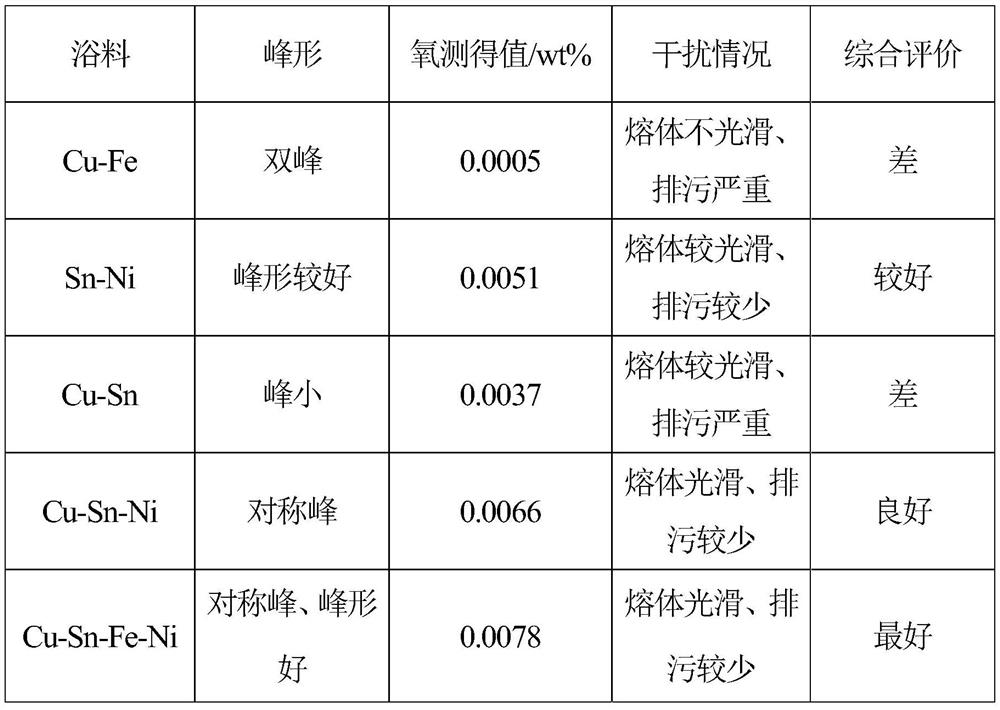

Method used

Image

Examples

Embodiment Construction

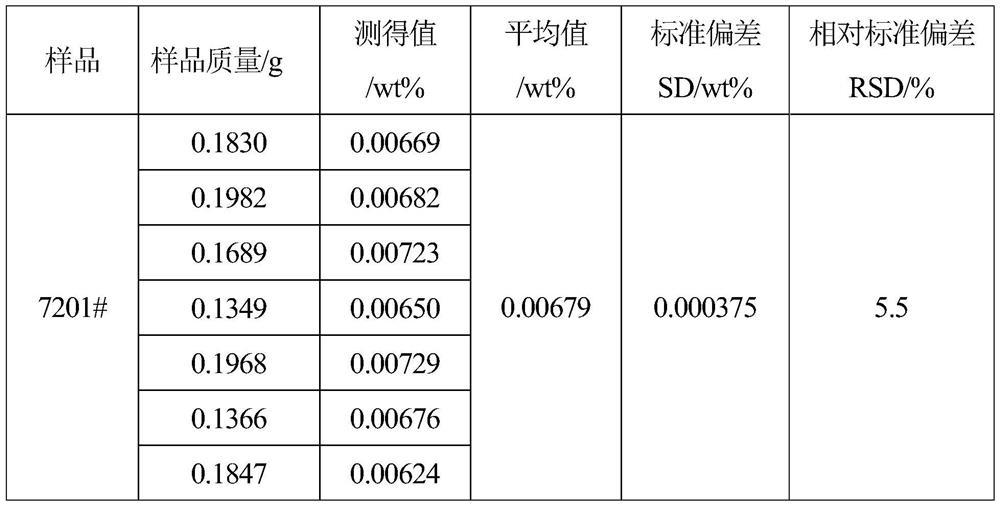

[0027] In the specific implementation process, the present invention adopts ON3000 pulsed infrared thermal conductivity oxygen and nitrogen analyzer (produced by Gangyan Nanke Detection Technology Co., Ltd.), and its main working parameters are as follows: carrier gas flow rate 400mL / min, degassing power 4600W, degassing power The gas time is 30s, the analysis power is 4200W, and the analysis time is 45s.

[0028] Oxygen standard sample in steel: GBW(E)020140(w(O)=0.014wt%); GBW(E)020143(w(O)=0.0075wt%); GBW(E)020137(w(O)=0.0034 wt%).

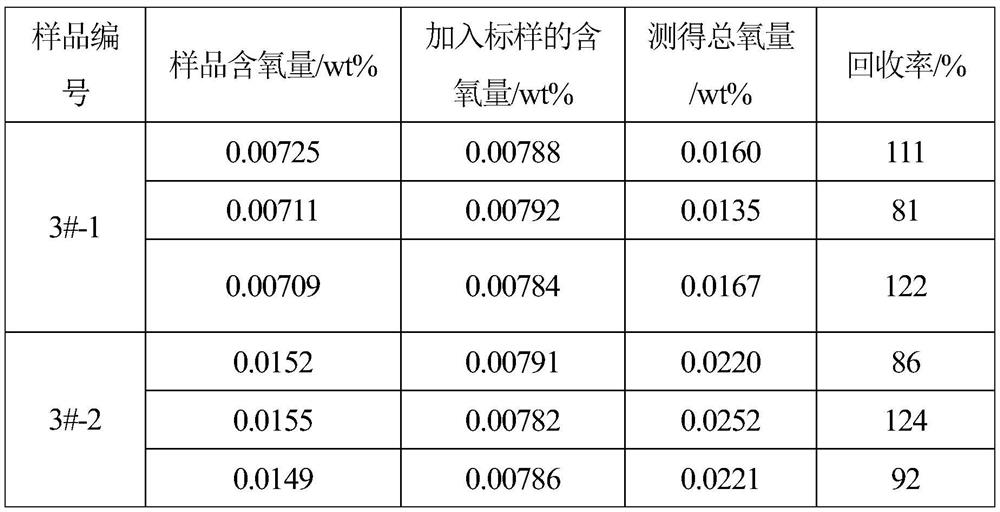

[0029] In this example, the standard curve method was used for quantitative analysis, which belongs to multi-point calibration. The abscissa of the standard curve represents variables that can be precisely measured, and the ordinate represents the response value of the instrument. Use three commercially available oxygen standard samples in steel to establish a standard working curve: weigh three standard samples each, and draw a standard curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com