Analysis method of layered cutting difference between left and right cutting edge of tool

An analysis method and a difference technology, which is applied in the field of layered cutting difference analysis of the left and right cutting edges of the tool, and the difference analysis field when the tool is cutting, and can solve the problems of inability to carry out difference analysis, unstable turning process, poor thread surface consistency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

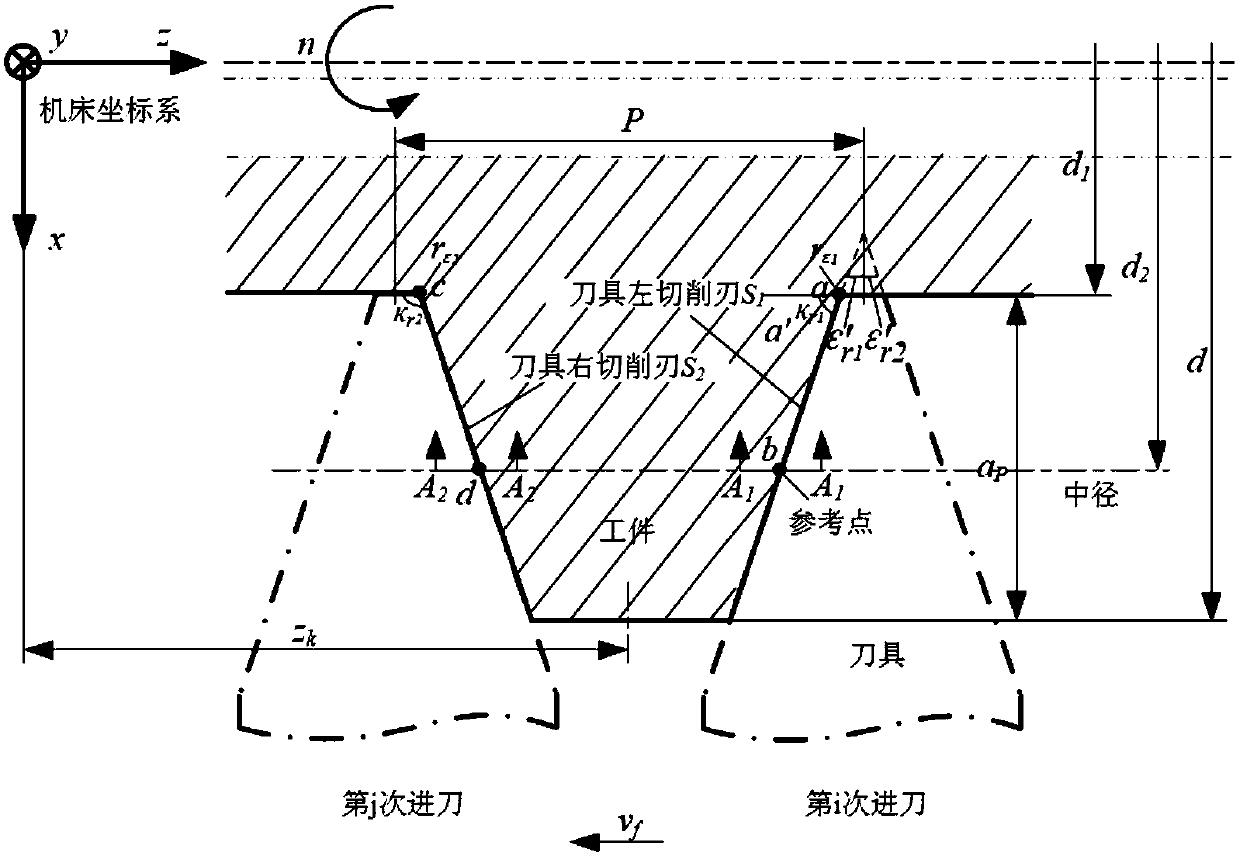

[0047] The specific implementation of the present invention is described in conjunction with the accompanying drawings. The method for analyzing the difference in layered cutting of the left and right cutting edges of the present invention specifically includes:

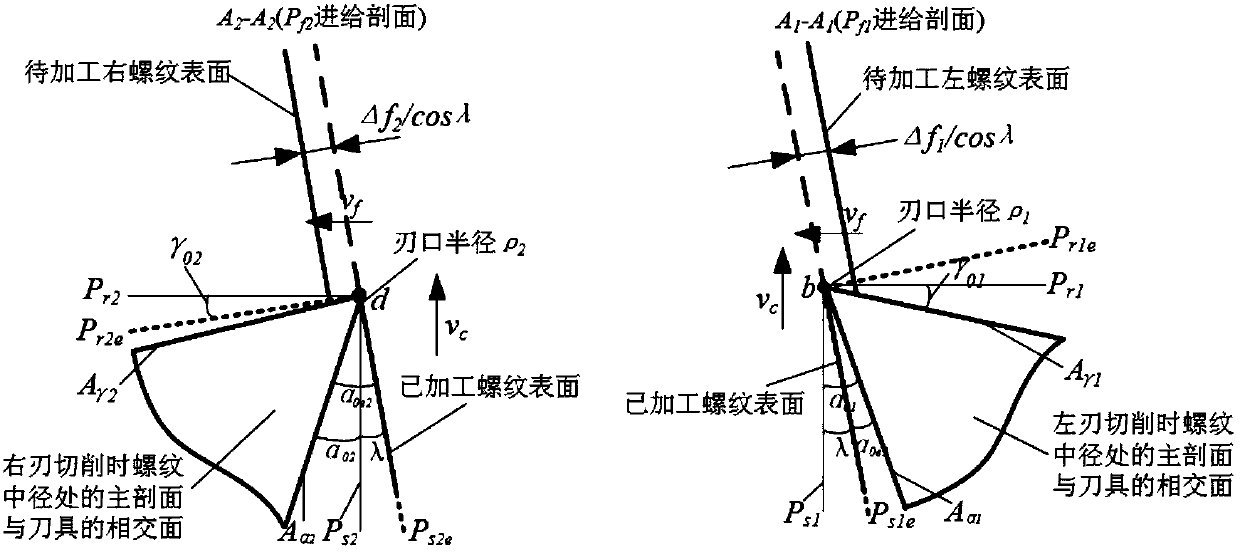

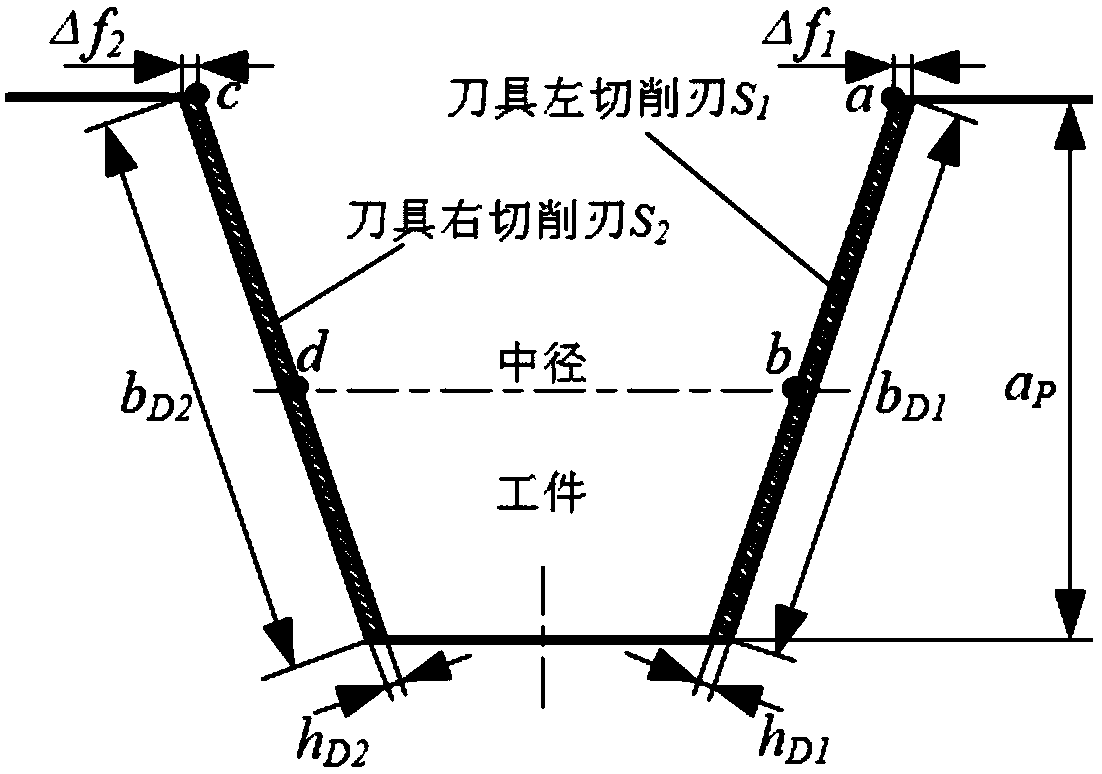

[0048] Step 1. Set the tool motion variable and geometric variable in the process of large-pitch thread turning, and obtain the actual working angle of the tool according to the geometric variable;

[0049] When cutting the left and right edges of large-pitch threads, because the working angle of the tool is different from the marked angle, the total cutting force and cutting stroke on the left and right edges of the tool are different, which will lead to inconsistent machining results on the left and right edges. During the initial cutting, the motion parameter variables of the left and right cutting edges of the tool are shown in Table 1:

[0050] Table 1 Basic variables of the cutting motion relationship between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com