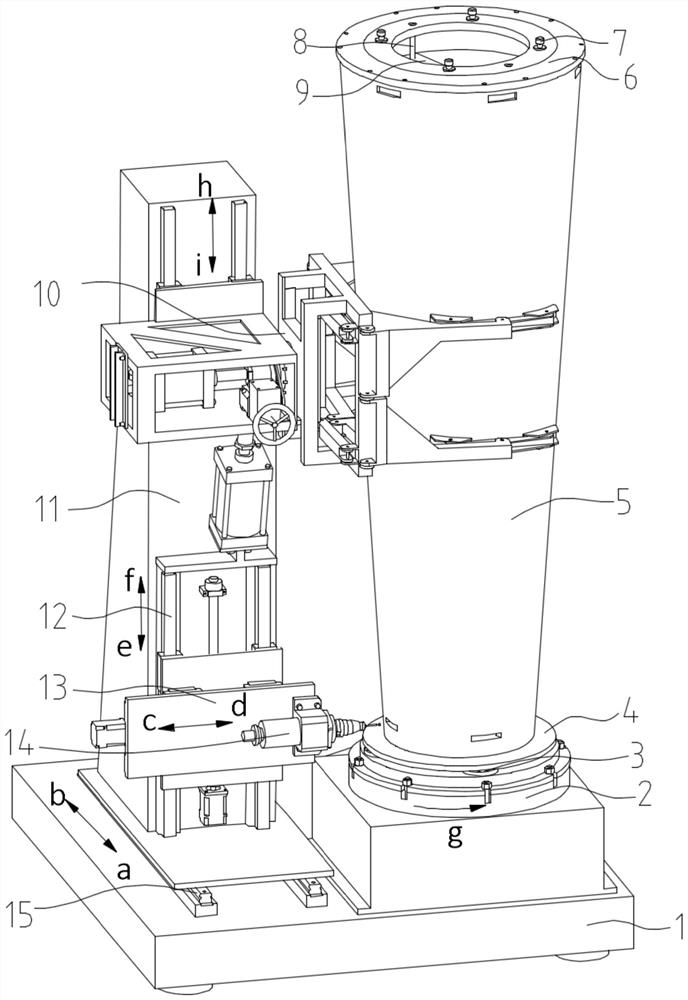

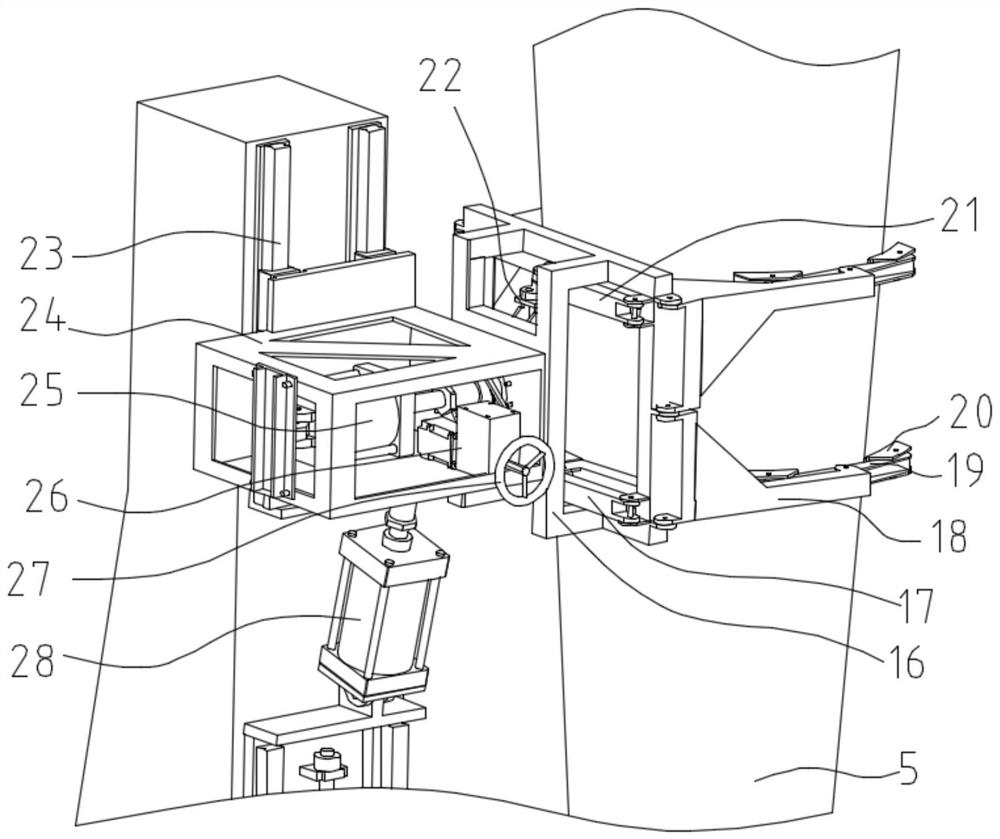

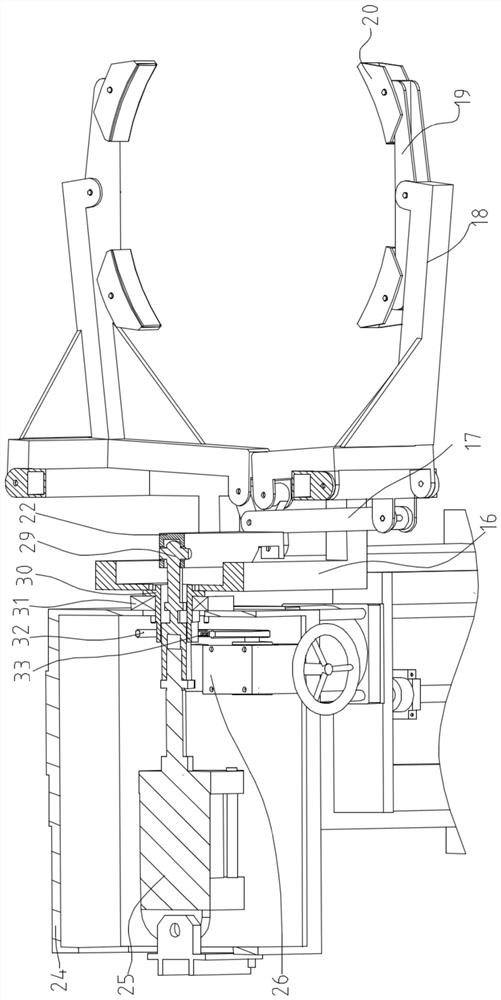

Window processing and measuring device for cone and method

A measuring device and a technology of a cone cylinder, which are applied in the field of cone cylinder processing, can solve the problems of low processing accuracy, increased processing difficulty in window trimming processing, and difficulty in detecting the position deviation and processing deviation of composite material windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: The CNC machining equipment of the cone adopts the automatic processing mode according to the position of the small-end metal window 37 model at a feed rate of V f It is 100mm / min, and the amount of cutting on the back is a p 3mm, side cutting amount a e Rough machining is 4mm; the cone CNC machining equipment adopts the automatic machining mode according to the position of the big-end metal window 37 model at a feed rate of V f It is 100mm / min, and the amount of cutting on the back is a p 3mm, side cutting amount a e Rough machining is done to 4mm.

Embodiment 2

[0074] Embodiment 2: According to the position of the small-end metal window 37 model, the CNC machining equipment of the cone adopts the automatic processing mode at a feed rate of V f It is 150mm / min, and the amount of cutting on the back is a p 5mm, side cutting amount a e Rough machining is carried out for 6mm; the cone CNC machining equipment adopts the automatic machining mode according to the position of the big-end metal window 37 model at a feed rate of V f It is 150mm / min, and the amount of cutting on the back is a p 5mm, side cutting amount a e Rough machining for 6mm;

Embodiment 3

[0075] Embodiment 3: According to the position of the metal window 37 model of the small end, the CNC machining equipment of the cone adopts the automatic processing mode at a feed rate of V f It is 200mm / min, and the amount of cutting on the back is a p 7mm, side cutting amount a e Rough machining is 8mm; the cone CNC machining equipment adopts the automatic machining mode according to the position of the big-end metal window 37 model at a feed rate of V f It is 200mm / min, and the amount of cutting on the back is a p 7mm, side cutting amount a e Rough machining is done to 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com