A test tube holding device

A clamping device and test tube technology, applied in the direction of test tube brackets/clamps, etc., can solve the problems of high risk, high equipment cost, and no provision, and achieve the effect of solving disinfection and sterilization resources, reducing experimental risks, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

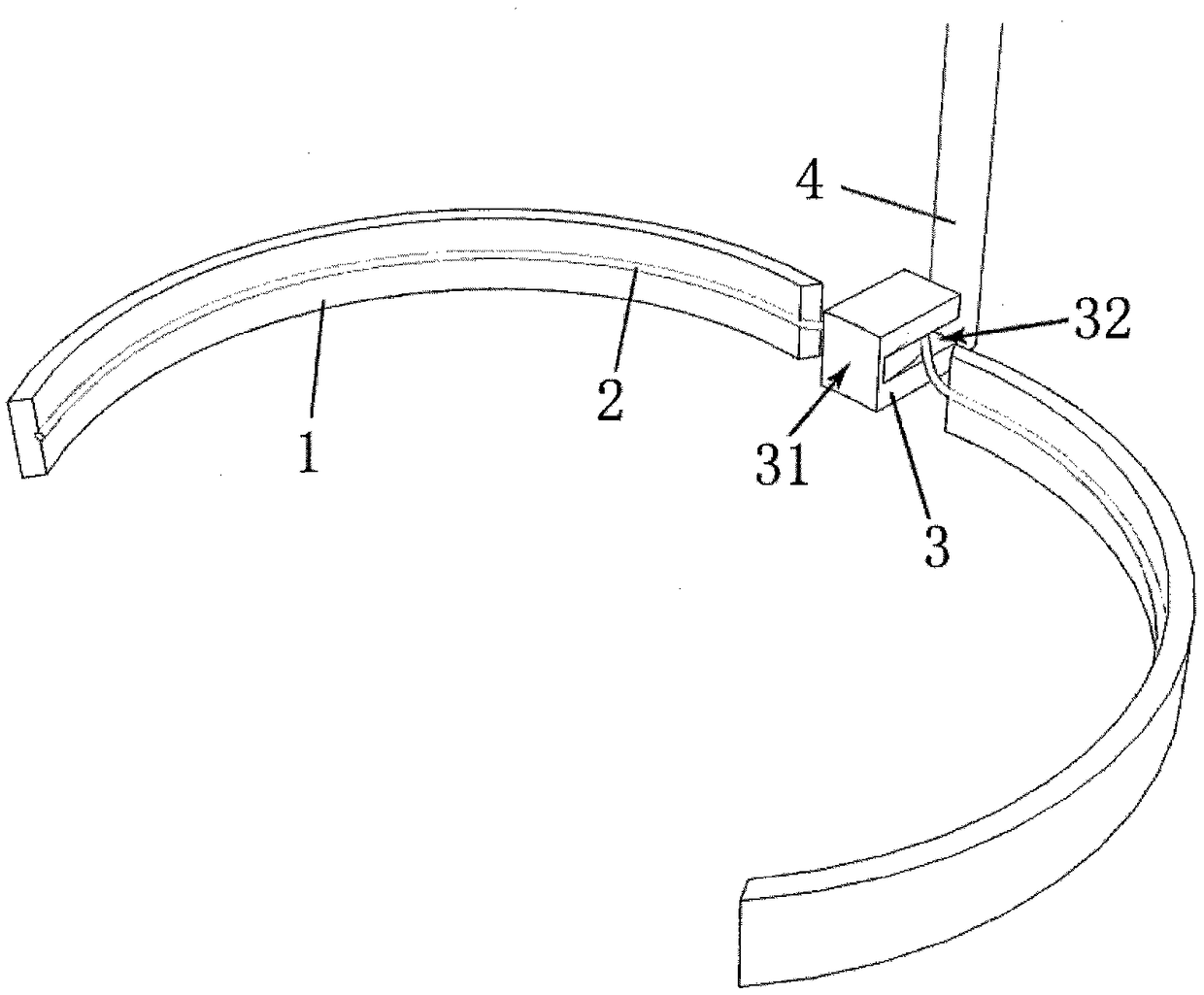

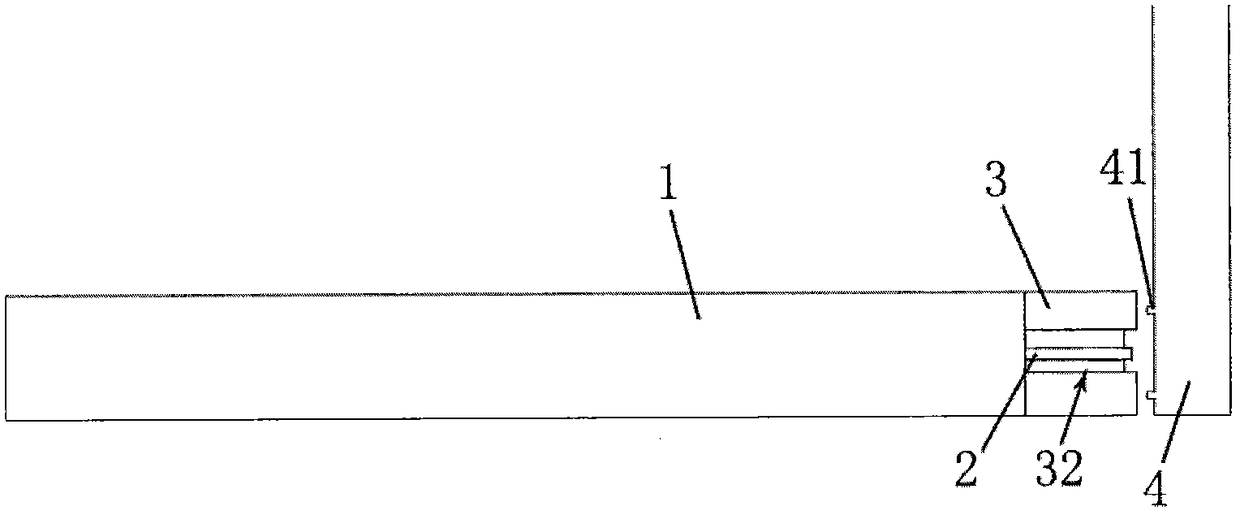

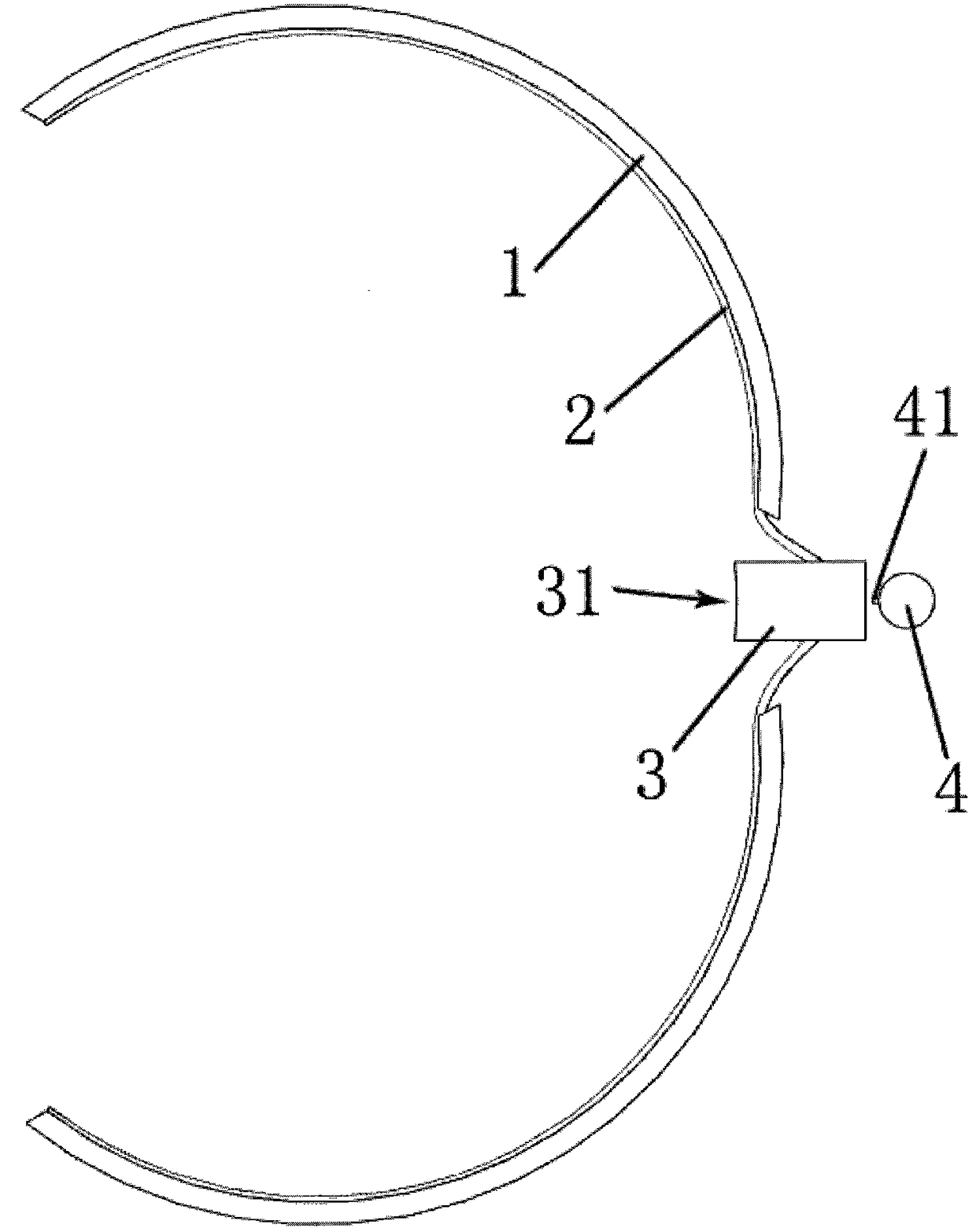

[0017] Such as Figure 1 to Figure 3 A test tube clamping device shown includes a clamping ring 1, a tension belt 2, a moving block 3, and a pole 4; the clamping ring 1 is an arc-shaped half ring with an angle less than 150°, and the number is two , the two clamping rings 1 are horizontally oppositely arranged; the moving block 3 is arranged in the middle of one end of the two clamping rings 1, and is connected with the proximal ends of the two clamping rings 1; the strut 4 is vertically arranged, The moving block 3 is movably fixed on the bottom of the pole 4, and the movable direction of the moving block 3 is perpendicular to the radial direction of the pole 4; 1 and the moving block 3 are set towards the pole 4 side.

[0018] When in use, you only need to set the top of the support rod 4 on the top cross bar of the laboratory,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com