Novel paper folding machine for forming paper box handles

A technology for an origami machine and a handle, which is applied in the field of new origami machines, can solve problems such as incompetence, and achieve the effects of simple and reliable structure, favorable for large-scale popularization and use, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

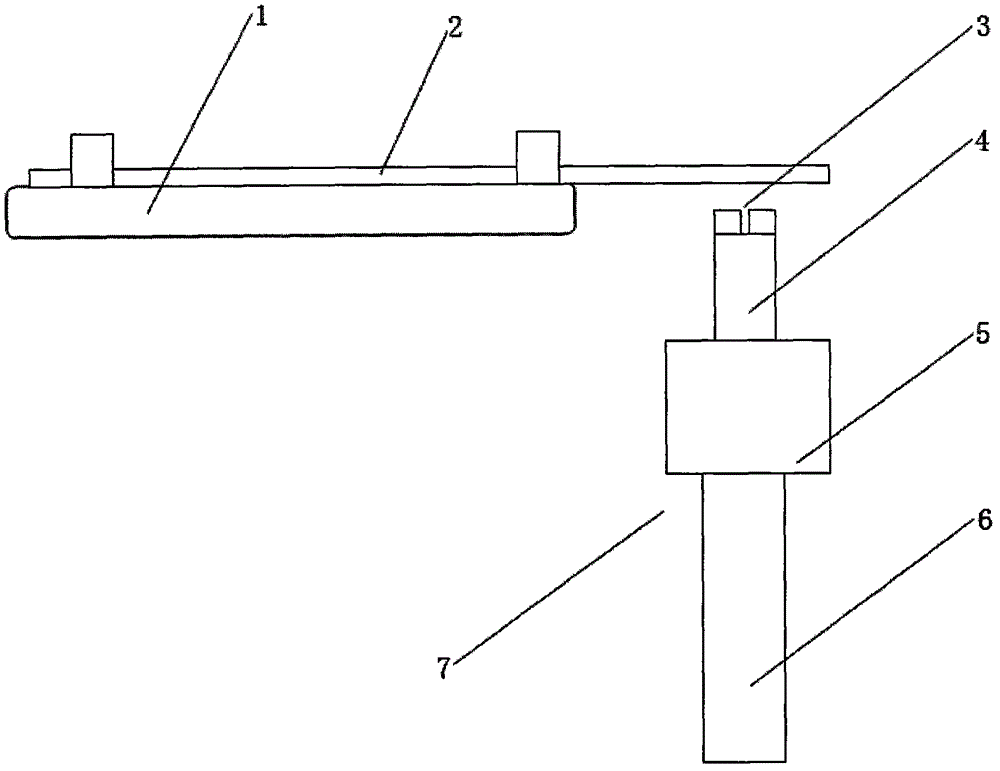

[0008] Such as figure 1 As shown, a new type of paper folding machine for carton handle forming includes a steel bar conveyor 1 and a steel bar bending pliers 7 installed on one side of the steel bar conveyor 1 and vertically arranged with the steel bar conveyor 1; the steel bar bending The pliers 7 include a rotating column 4, the top of the rotating column 4 is provided with a steel bar bayonet 3, and the rear end of the rotating column 4 is connected to a motor 5; the steel bar bending pliers 7 are installed on the slide rail 6.

[0009] A new type of paper folding machine for forming carton handles described in this patent, when working, the steel bar 2 is first transported to the designated position by the steel bar conveyor 1, and the part of the steel bar 2 to be bent is aligned with the steel bar bending pliers 7 Adjust the steel bar bayonet 3 position, adjust the steel bar bending pliers 7 to move forward along the slide rail 6 to the steel bar bayonet 3 to block the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap