Rail clamping device

A technology of rail clamps and splints, which is applied in the direction of traveling mechanism, load hanging components, transportation and packaging, etc. It can solve the problems of affecting work efficiency, easy damage of rail clamps, and affecting maintenance work, etc., and achieves the effect of convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

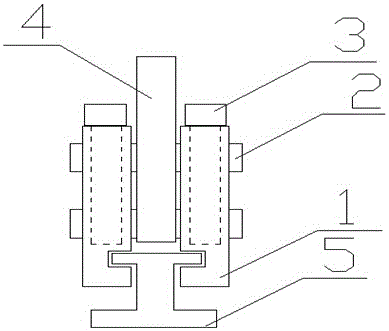

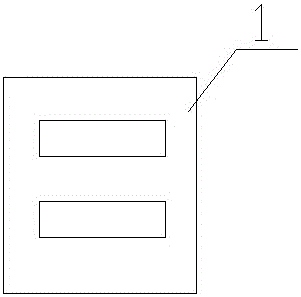

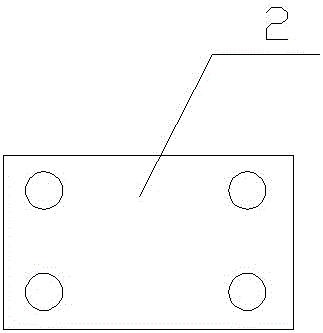

[0013] Such as figure 1 As shown, the present invention discloses a rail clamp, comprising: a splint 1, a limiting plate 2, a bolt 3, a fixing plate 4, and a track 5. The lower end of the left plane of the splint 1 is provided with a "U"-shaped slide rail Hole, the upper end of the "U" type slide rail hole is provided with two vertical cuboid holes, and the size of the two rectangular holes on the splint 1 is exactly the same, and the left end of the splint 1 is placed with the same The splint 1, and the "U"-shaped slide rail holes of the two splints 1 are opposite, the two splints 1 just clamp the upper end of the track 5, and the two splints 1 are connected by the limit plate 2 and connected by the bolt 3 The limiting plate 2 is fixed, and the two limiting plates 2 pass through the two cuboid-shaped holes of the fixing plate 4 .

[0014] The distance between the two splints is equal to the width of the fixed plate

[0015] The present invention is implemented like this: in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com