A branch position adjustment mechanism

A technology of regulating mechanism and row divider, which is applied in the fields of crop dividers, harvesters, agricultural machinery and implements, etc. It can solve the problems of different sugarcane growth conditions, complex terrain, and unsatisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

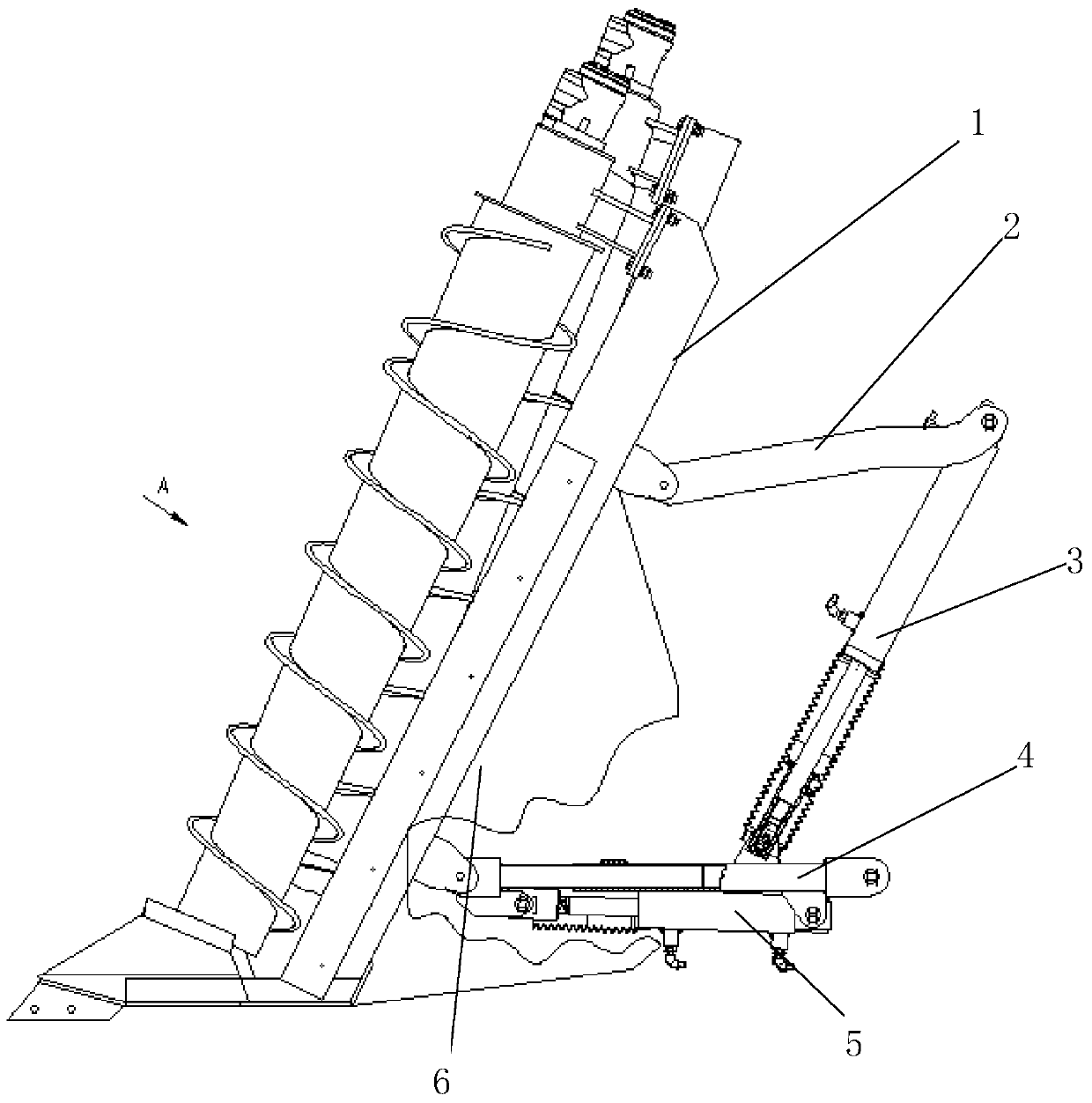

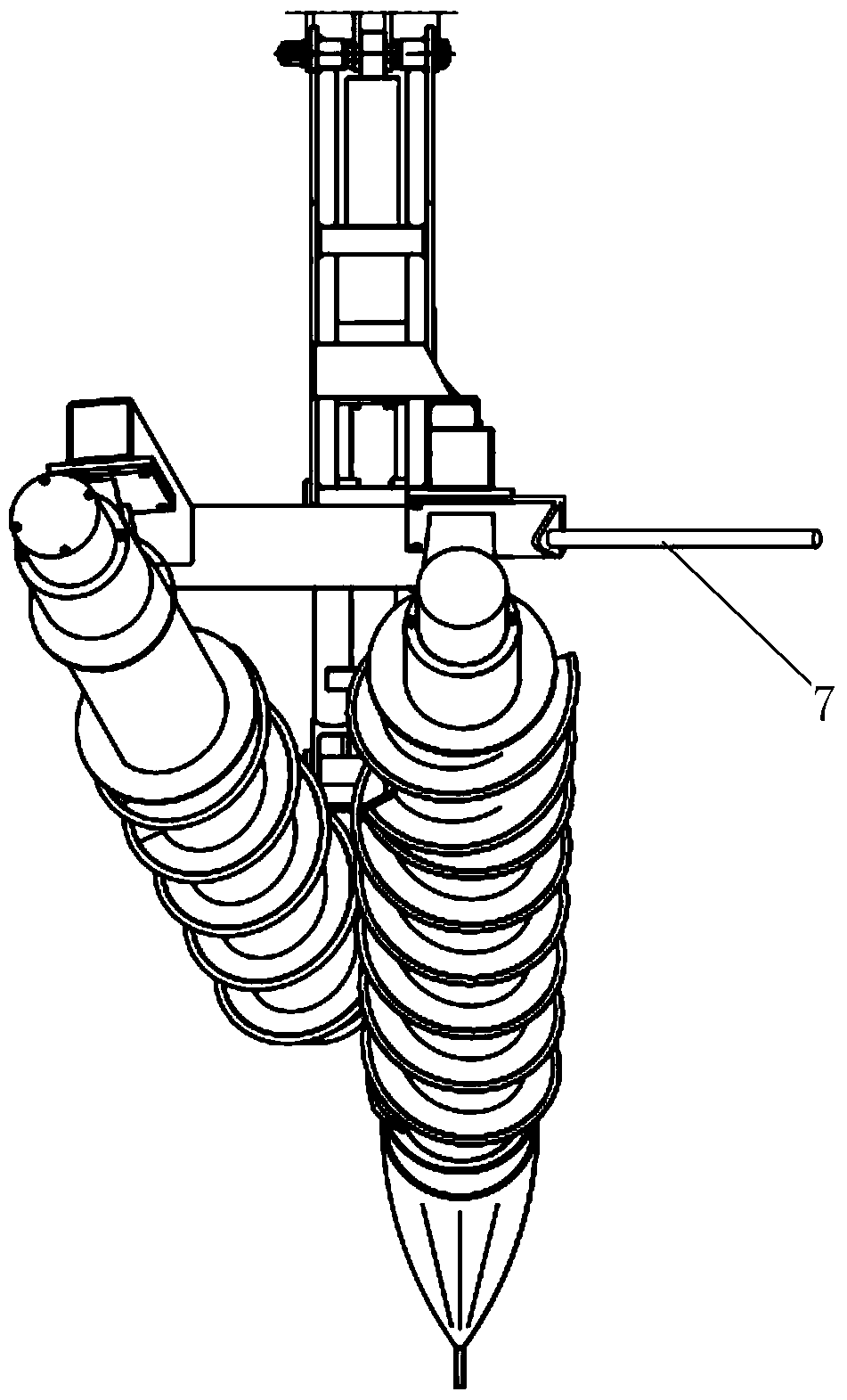

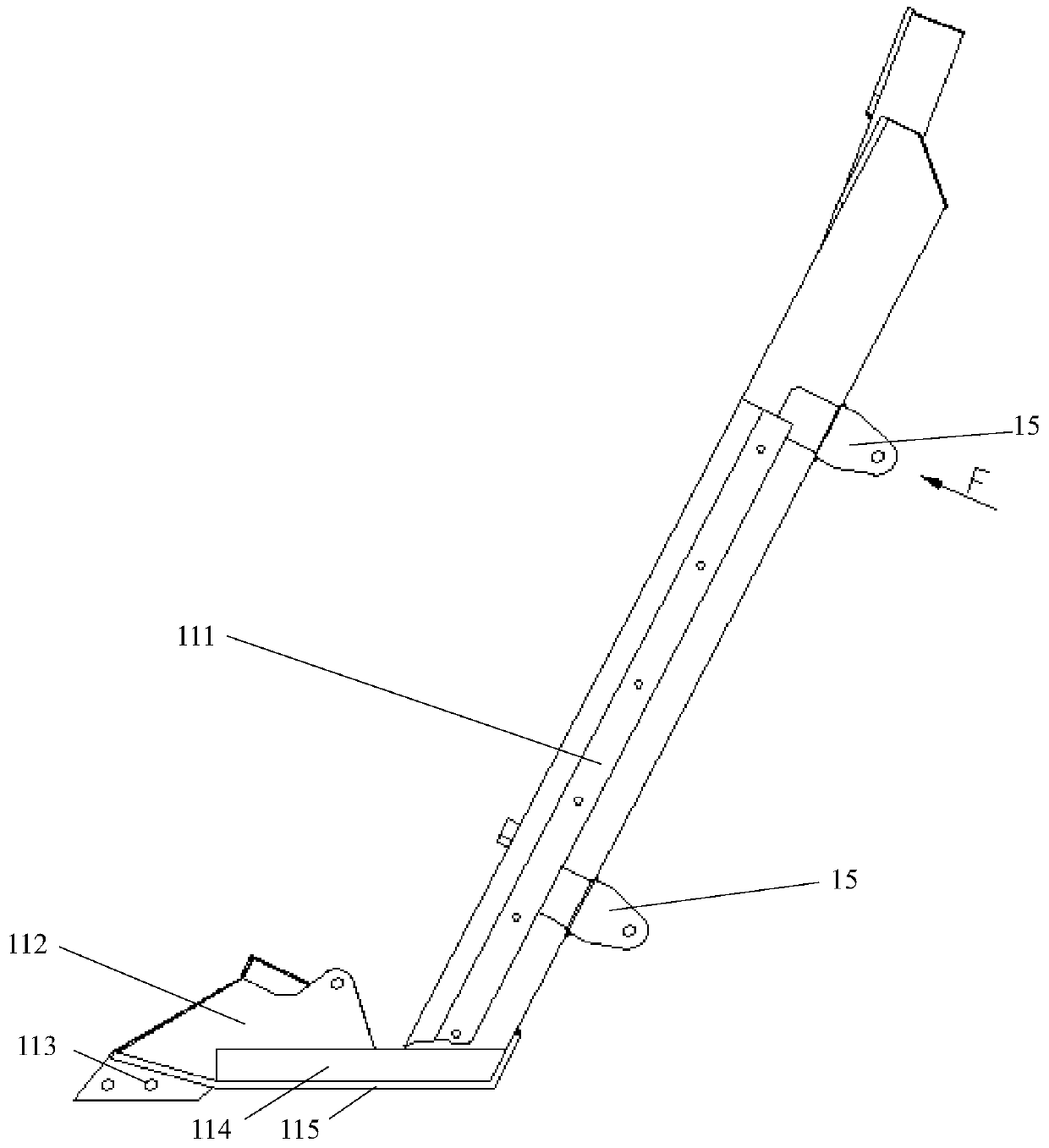

[0033] The position adjustment mechanism of the distributor of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0034] Such as figure 1As shown, a branch position adjustment mechanism includes a support mechanism 1, an upper connecting frame 2, an upper cylinder or an oil cylinder 3, a lower connecting frame 4, and a lower cylinder or an oil cylinder 5; There is a group of lifting support bases 15, the lifting support bases 15 are welded with the main support column 17, and are perpendicular to each other, and the lifting support base reinforcement ribs 16 are also provided at the connection; One end of the connecting frame 3 is movably connected, one end of the upper cylinder or oil cylinder 3 is movably connected with the other end on the upper connecting frame 2, and the piston rod joint at the other end of the upper cylinder or oil cylinder 3 is movably connected to the upper side bushing of the lower connecting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com