A kind of transparent epoxy polyisobutylene potting compound

A polyisobutylene and polyisobutylene resin technology is applied in the field of polymer materials and optoelectronic device packaging, and achieves the effects of good adhesion and sealing, low ionic impurity content in materials, and strong anti-ultraviolet aging ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

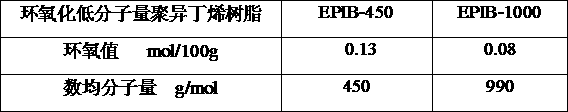

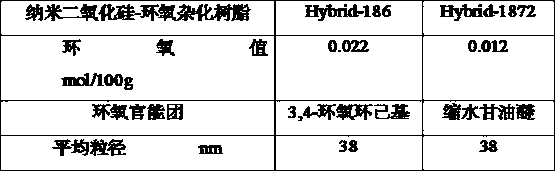

[0024]

[0025]

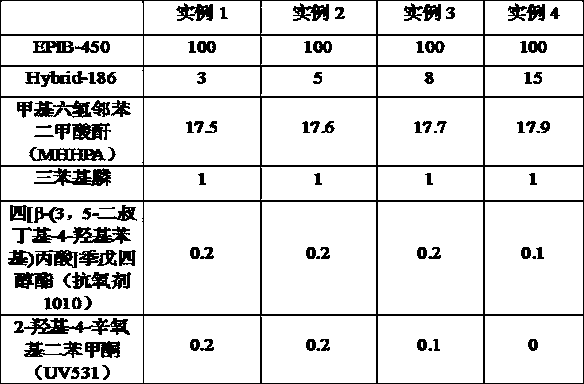

[0026] Table 1 Chemical composition of transparent potting compound (parts by mass)

[0027]

[0028] Stir and mix Hybrid-186 and EPIB450 according to the mass parts values listed in Table 1, and ultrasonically disperse to obtain a mixed resin; add antioxidant 1010 and light stabilizer UV531 to the mixed resin; dissolve triphenylphosphine into MHHPA, and then add and mix In the resin, stir evenly to obtain a colorless and transparent potting compound. Apply the potting material to a clean glass slide with a 1mm scraper rod, and heat and cure in an oven. The curing process was heating at 120°C for 4 hours, then heating at 130°C for 2 hours, and finally heating at 150°C for 45 minutes, and cooling with the furnace to obtain samples.

[0029] The transmission spectrum of the sample was measured with a UV-Vis spectrophotometer, and the value at 550 nm was taken as the light transmittance of the sample. The dynamic mechanical properties of the samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap