A kind of preparation method of ultraviolet absorber uv-p

A UV-P, absorber technology, applied in the direction of organic chemistry, can solve the problems of increased workload, inaccuracy, manual control in batch mode, etc., to reduce pollution, reduce demand, and avoid excessive reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

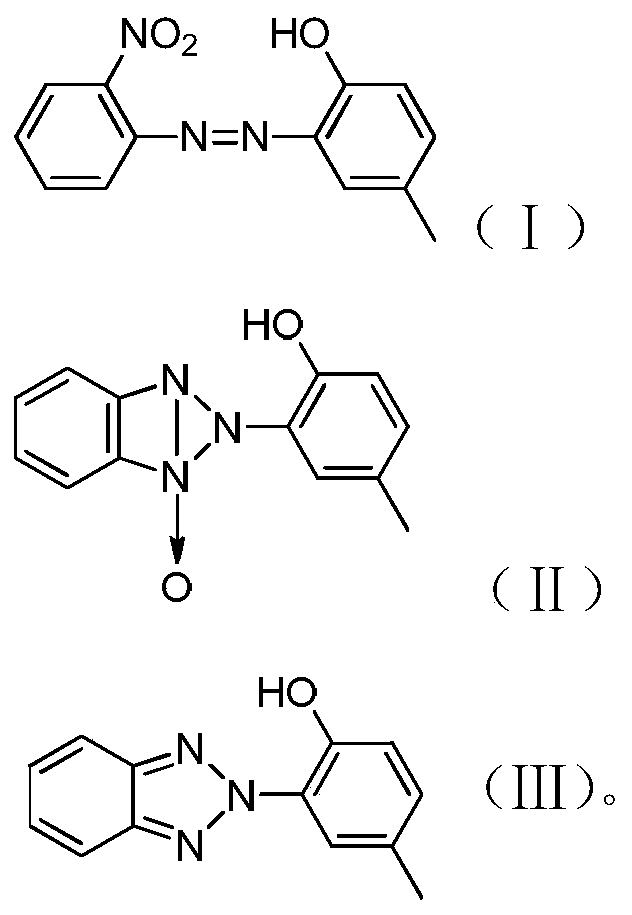

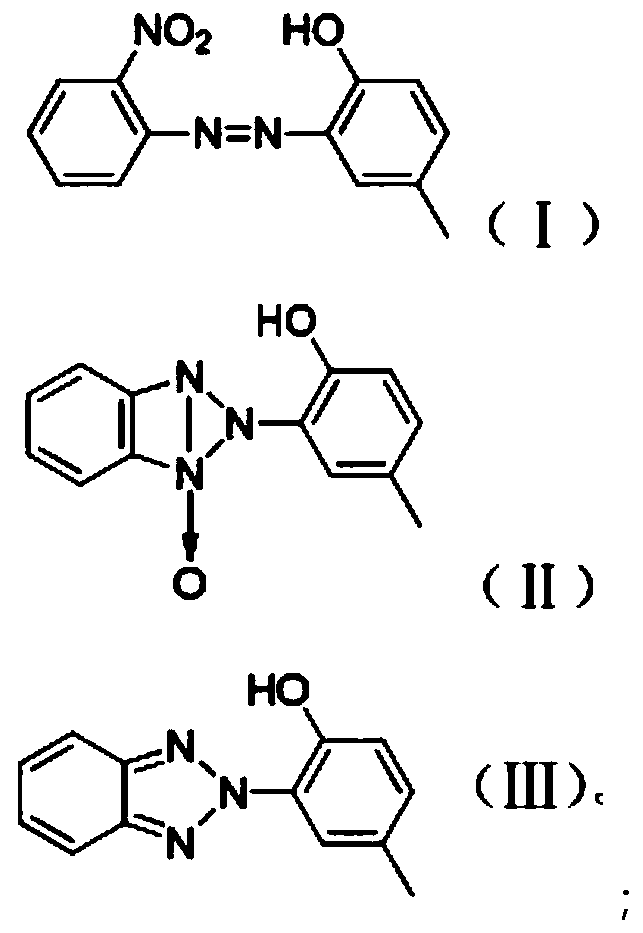

Image

Examples

Embodiment 1

[0037] ①According to the weight ratio, aluminum powder:adsorbent=0.5:1, add metal powder and coke to the double-helix mixer and mix evenly;

[0038] ② Press molding;

[0039] ③Under nitrogen protection, control the temperature to 1200°C for sintering;

[0040] ④ Cooling with water and molding to obtain a reducing agent the size of soybean grains, with a diameter of 2mm.

Embodiment 2

[0042] ① According to the weight ratio, iron powder: adsorbent = 2: 1, add metal powder and clay to the double-helix mixer and mix evenly;

[0043] ② Press molding;

[0044] ③Under nitrogen protection, control the temperature to 700°C for sintering;

[0045] ④ Cooling with water and molding to obtain a reducing agent the size of soybean grains with a diameter of 6mm.

Embodiment 3

[0047] ① According to the weight ratio, zinc powder: adsorbent = 1.5: 1, add metal powder and coke to the double-helix mixer and mix evenly;

[0048] ② Press molding;

[0049] ③Under nitrogen protection, control the temperature to 900°C for sintering;

[0050] ④ Cooling with water and molding to obtain a reducing agent the size of soybean grains, with a diameter of 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com