A suspended cross bar dipping device

A cross-bar and hanging technology, which is applied to the device and coating of the surface coating liquid, can solve the problems such as the inability to guarantee the uniform thickness of the paint film on the surface of the cross-bar, the troublesome painting process, and the paint sagging, etc. Appearance, guarantee the quality of the product, avoid the effect of sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

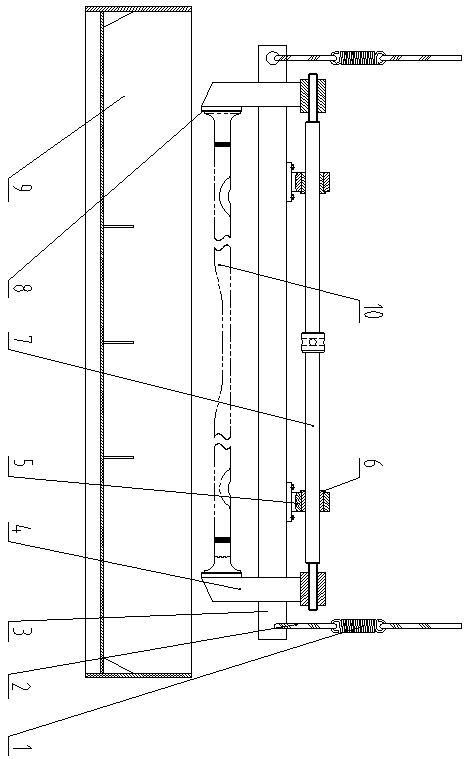

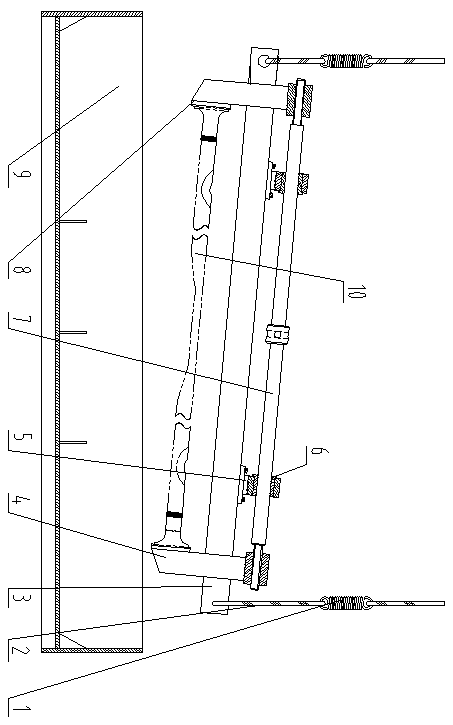

[0011] Embodiment: A suspension-type cross-rod dipping device, including a tension spring 1, a rope 2, a boom 3, a screw chuck 4, a double-ended screw seat 5, a sliding sleeve 6, a double-ended screw 7 and a paint dipping box 9 , the paint dipping box is located under the boom, and there are two double-ended screw seats and two screw chucks, and the two double-ended screw seats are respectively fixed on both sides of the center line in the length direction of the boom and are symmetrically distributed. The screw clamps are movably connected to both sides of the center line in the length direction of the boom, and are distributed symmetrically. The sliding sleeve is movably connected to the double-ended screw seat. Below, the other end of the screw chuck is threadedly connected with the end of the double-ended screw, one end of a screw chuck located on the right side of the length direction of the boom is located below the boom, the other end of the screw chuck is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com