Push-pull self-locking cable connector

A cable connector, push-pull self-locking technology, applied in the direction of connection, parts of the connection device, circuits, etc., can solve the problems of troublesome connection of the shell and end sleeves, poor self-locking performance, etc., to improve the anti-vibration effect and ensure the connection Effect, the effect of fast connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

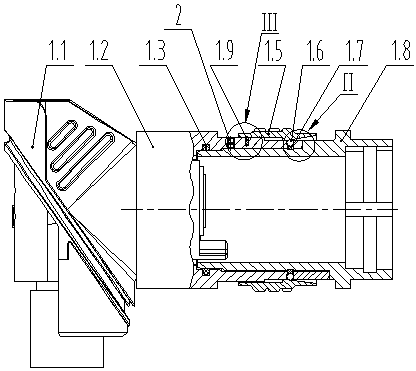

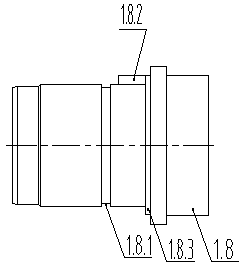

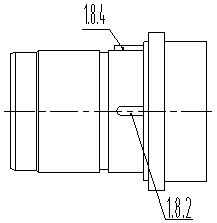

[0028] The push-pull self-locking cable connector shown in the attached figure includes seat cover 1.1, shell 1.2, sealing ring 1.3, connecting sleeve 1.5, steel ball I 1.6, circlip II 1.7, end sleeve 1.8; shell 1.2 is placed flat, the left end Set on the right end of the seat cover 1.1, the right end is set on the left end of the end cover 1.8; the connecting cover 1.5 is set on the shell 1.2; the outer wall of the end cover 1.8 on the right side of the right end of the shell 1.2 is provided with a shoulder 1.8.3; the end cover 1.8 shoulder 1.8 .3 The left end face is provided with axial protrusions I1.8.2 and axial protrusions II1.8.4 at circumferentially staggered positions; when the shell 1.2 and end sleeve 1.8 are in a combined state, the right end face of shell 1.2 and the shoulder of end sleeve 1.8 1.8.3 The left end face is comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com