Three-stage platform carrying structure of wrecker

A wrecker and platform technology, which is applied in the direction of vehicles, motor vehicles, loading/unloading, etc., can solve the problems of not being able to adapt to the back load of the chassis, damaging the vehicle, and being prone to collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

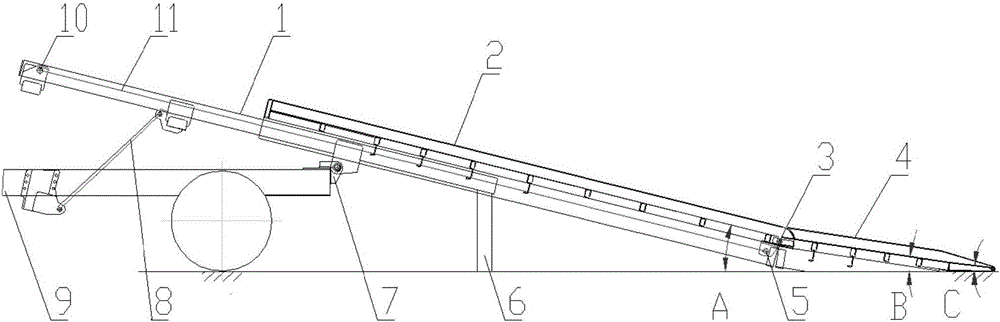

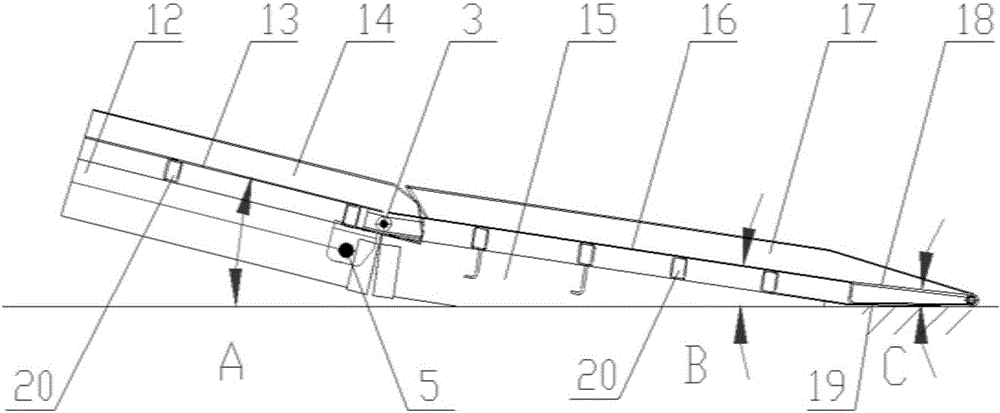

[0021] Such as figure 2 As shown, a three-level platform back-loading structure of a wrecker is provided with a sub-frame 1, a first-level large platform 2 and a second-level and third-level small platform 4, and the large second-level and third-level small platforms are hinged through the first hinge point 3. The grooved slideway 12 of the first-level large platform and the grooved slideway 15 of the second- and third-level small platform are embedded in sliding fit with the guide rail of the rectangular longitudinal beam of the subframe, and a platform is provided between the subframe 1 and the lower chassis longitudinal beam 9 The luffing cylinder 8, the subframe 1 is hinged with the tail of the chassis longitudinal beam through the hinge point 7, the end of the subframe is provided with outriggers 6, the bottom of the first-level large platform 2 and the front end of the subframe 1 are respectively provided with platform telescopic cylinder hinge points 5 , 10. Among the...

Embodiment 2

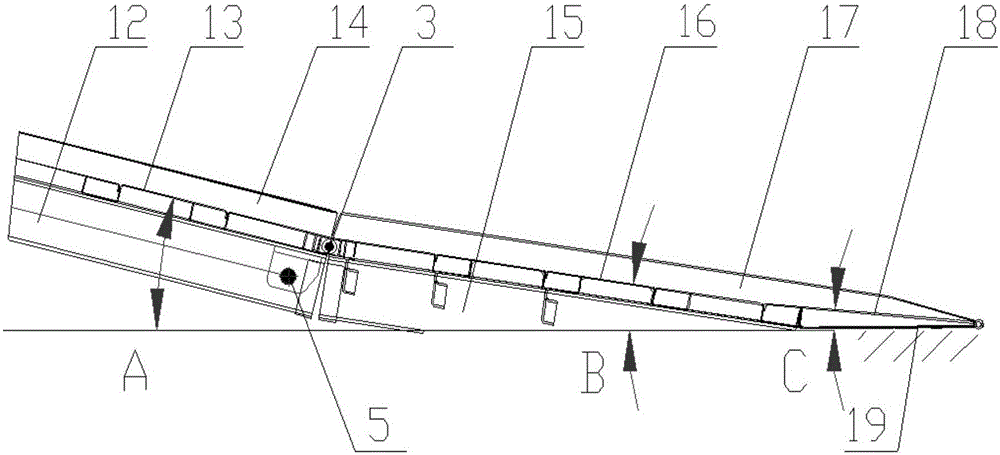

[0022] Example 2 : In this embodiment, the platform boards in the first-level large platform 2 and the second- and third-level small platforms 4 in embodiment 1 are replaced by platform stamping and bending plates. The structure of the platform stamping and bending plates is as follows Figure 4 As shown, its strength and support effect are better, and the beam can be supported without a rectangle.

[0023] Such as image 3 As shown, a three-level platform back-loading structure of a wrecker is provided with a sub-frame 1, a first-level large platform 2 and a second-level and third-level small platform 4, and the large second-level and third-level small platforms are hinged through the first hinge point 3. The grooved slideway 12 of the first-level large platform and the grooved slideway 15 of the second- and third-level small platform are embedded with the rectangular longitudinal beam guide rail of the subframe in a sliding fit, and a platform transformer is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com