Device and method for synchronously testing stretching, compression and bend-stretching rebound moduli of pavement material

A pavement material, synchronous testing technology, applied in the direction of measuring device, analyzing material, testing material strength by applying a stable bending force, etc., can solve the problem of large error of flexural modulus, unable to objectively reflect the deformation resistance of material or structure, Can not accurately reflect the real mechanical properties of materials and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Now, the present invention will be further described by taking the beam specimen in the cement-stabilized crushed stone mixture as an example.

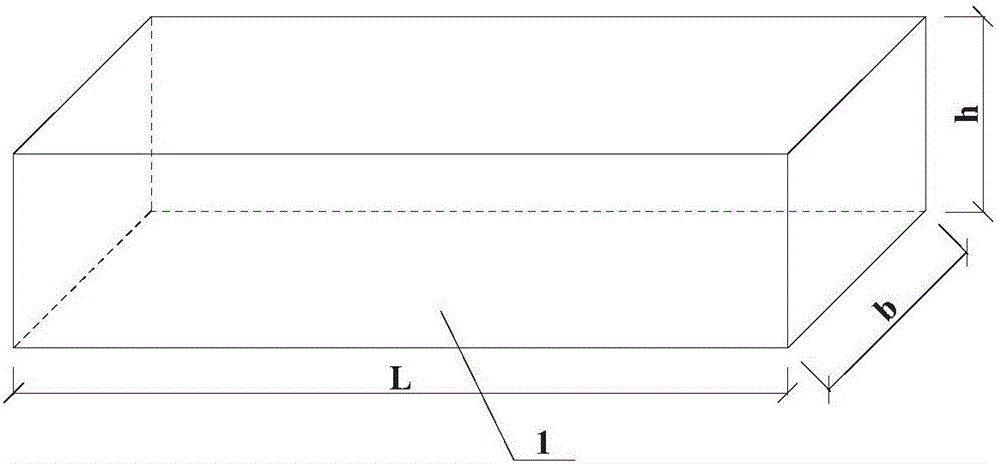

[0113] 1) The middle beam specimen 1 with the size of 100mm×100mm×400mm was prepared in strict accordance with the T0844-2009 method of "Test Regulations for Inorganic Binder Stabilizing Materials of Highway Engineering", such as figure 2 shown. Follow the T0845-2009 standard health care method for 90 days.

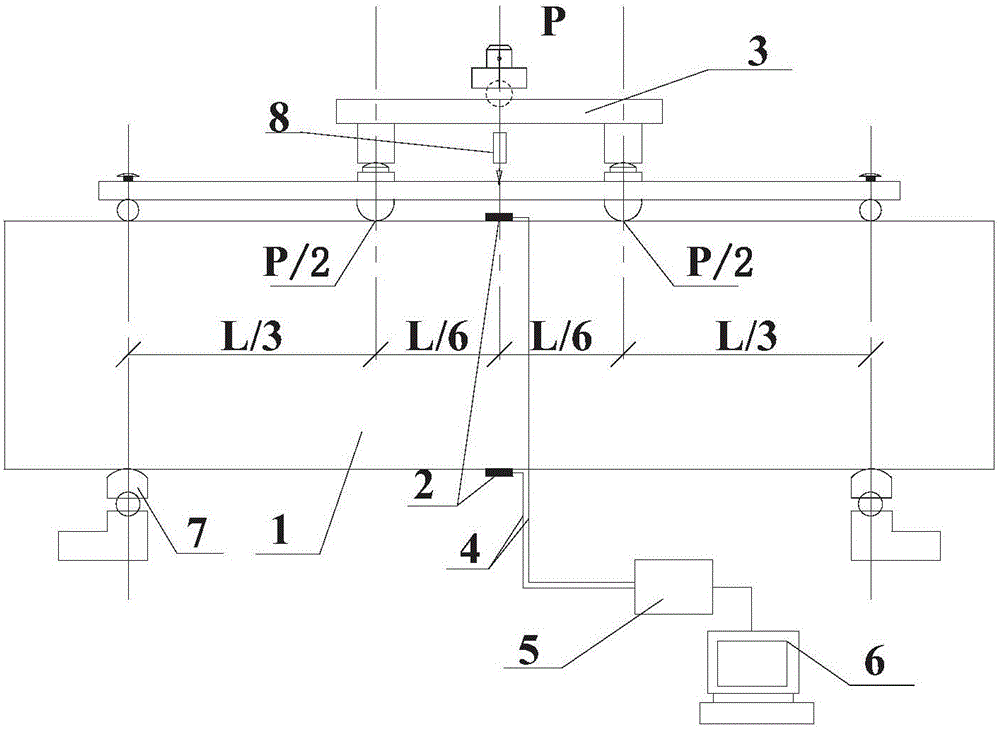

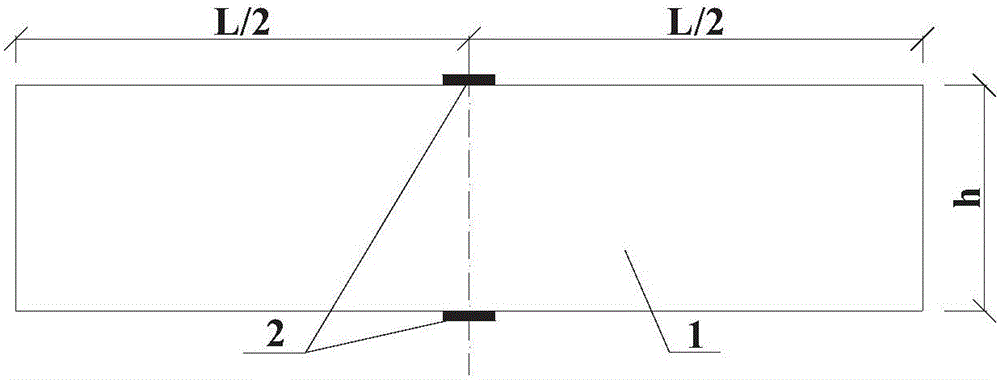

[0114] 2) Use cement mortar to repair the cover of the specimen with the 2 strain gauges and the simply supported place, and glue the strain gauge 2 to the upper and lower surfaces of the beam specimen 1 span with super glue. Pay attention to the bonding of the wires and the distance Make it as large as possible to avoid short circuit caused by deformation of the test piece during testing, and then connect the wire and wire 4 by electric welding, such as image 3 and Figure 4 shown.

[0115] 4) Place the specimen on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com