Composite cold-source hot dry rock thermoelectric power generation system and method

A technology for thermoelectric power generation and dry hot rock, which is applied in the directions of generators/motors, electrical components, etc., and can solve the problems of high construction costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

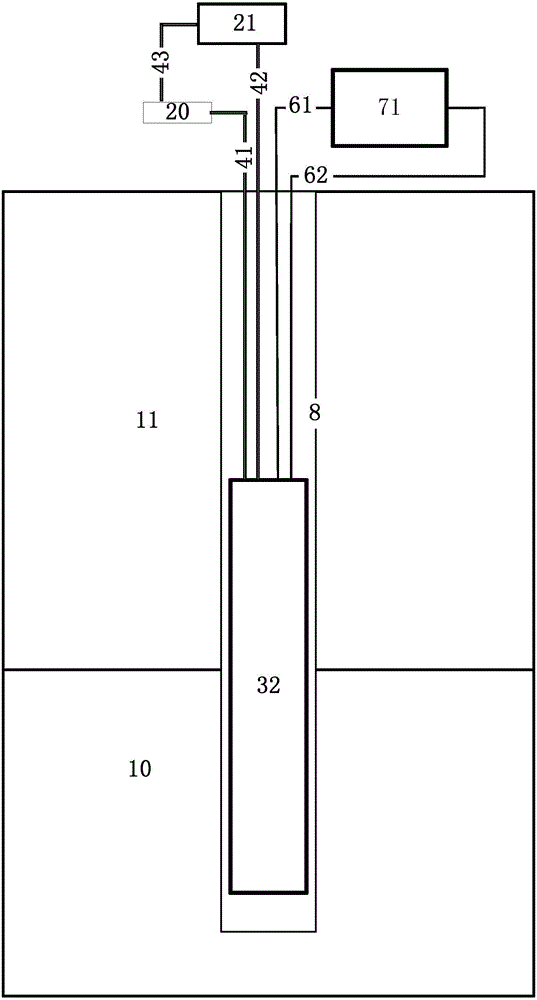

[0018] Such as figure 1 As shown, the hot dry rock reservoir 10 is a high-temperature rock mass with a buried depth of several thousand meters, a temperature greater than 200°C, and no fluid inside or only a small amount of underground fluid; From layer 10 to the surface covered by sedimentary rock or soil, the temperature of the formation gradually decreases from bottom to top, which is lower than the temperature of dry hot rock reservoir; wellbore 8 is a hole structure drilled through the formation, passing through The hot dry rock overlying formation 11 and the hot dry rock reservoir 10; the wellbore 8 part within the range of the hot dry rock overlying formation 11 is completed by casing cementing, and the wellbore 8 part within the range of the hot dry rock reservoir 10 is completed with open hole The well completion method is completed; the wellbore 8 provides access for the downhole thermoelectric power generation module 31 , the cooling medium inflow pipeline 41 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com