Airflow power generation system and method

A power generation system and airflow technology, applied in wind power generation, engines, wind turbines, etc., can solve the problems of wasting heat, fluctuating wind direction, increasing investment costs, etc., so as to improve power generation efficiency, reduce air conditioning load, and increase power generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

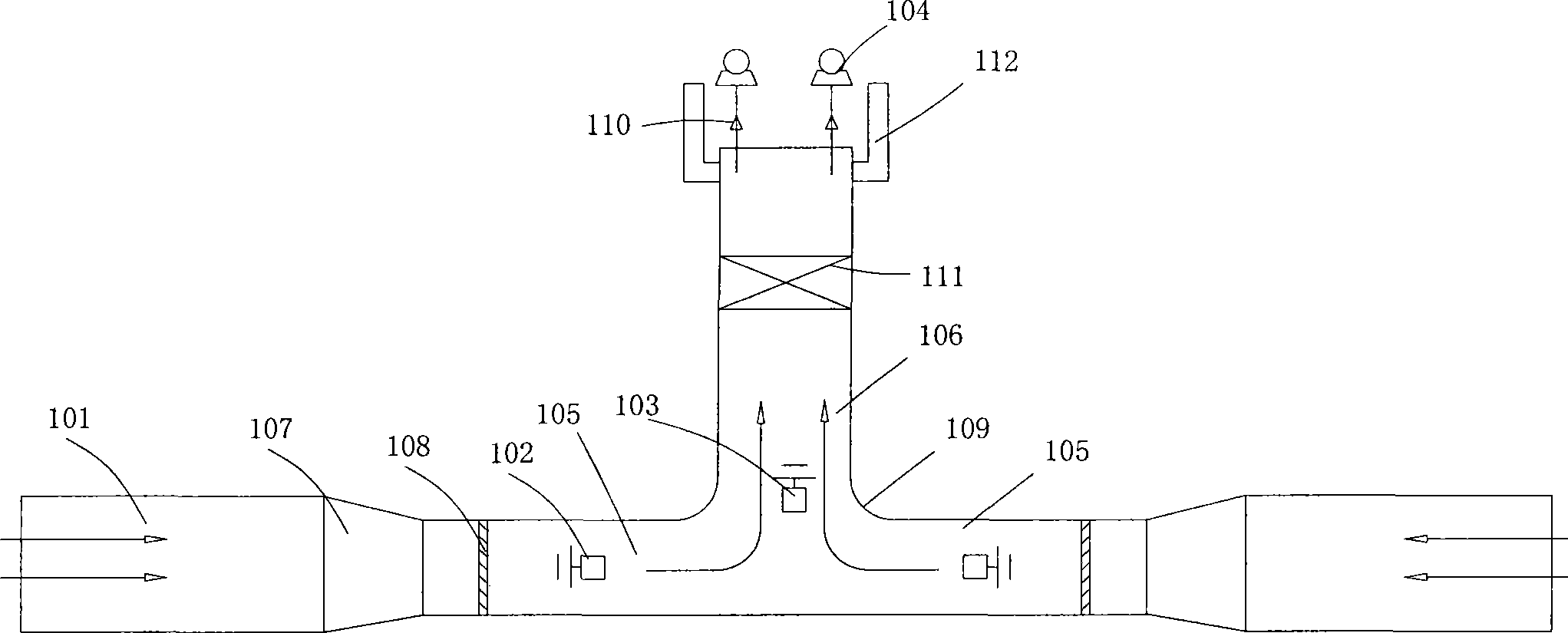

[0081] Under the road surface 207, an appropriate amount of metal pipes 201 are shallowly buried, and each metal pipe 201 is connected with a heat exchange rib 209, and the air inlets 206 of the metal pipes 201 are all located beside the road at a suitable place, and all the metal pipes 201 After the gas outlets are connected in parallel, they are connected to the inlet of the pipeline 205 installed on the intermediate isolation belt 208, and the outlet of the pipeline 205 is connected with the bellows 204 erected on the isolation belt 208. The road surface 207 is used as a heat source to heat the air in the metal pipe 201 to form a hot air source; while the pipeline 205 is used as a channel, and an appropriate amount of turbine generator set 202 is installed inside the pipeline 205 and is located at the position of the isolation zone. An appropriate amount of unpowered fans 203 are installed on the top of the bellows 204, and these unpowered fans 203 are arranged side by side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com