Dish washer body component

A technology for dishwashers and components, which is applied to parts of tableware washing machines/rinsing and washing machines, tableware washing machines/rinsing machines, cleaning equipment, etc., and can solve problems such as many washing dead ends, high cost, and poor washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

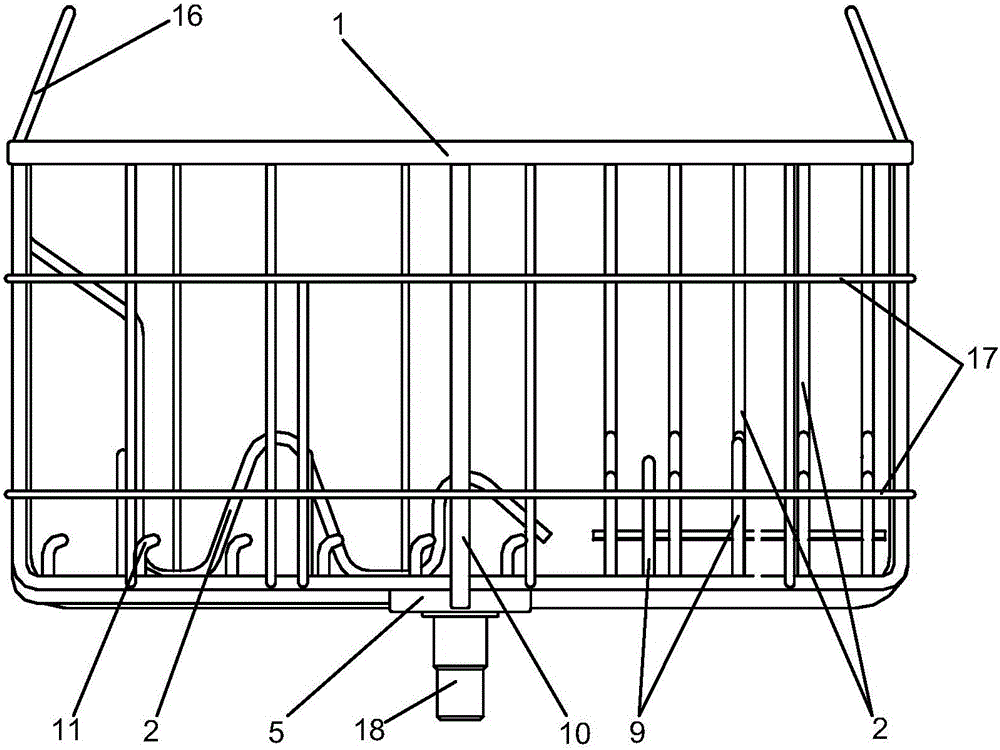

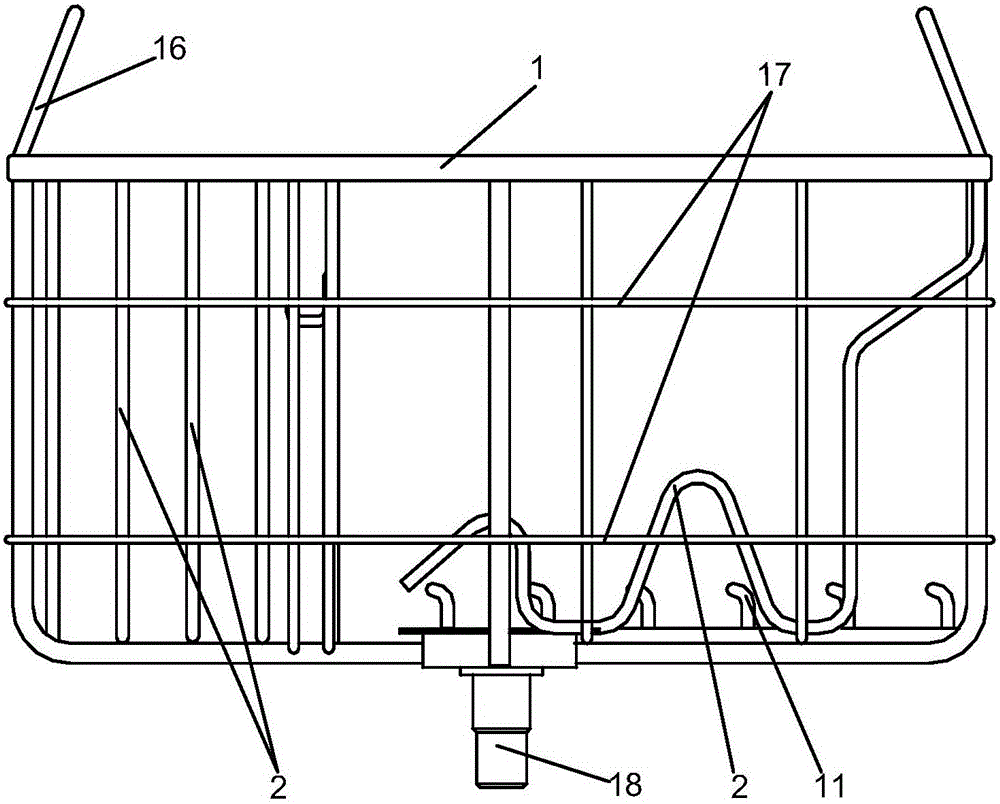

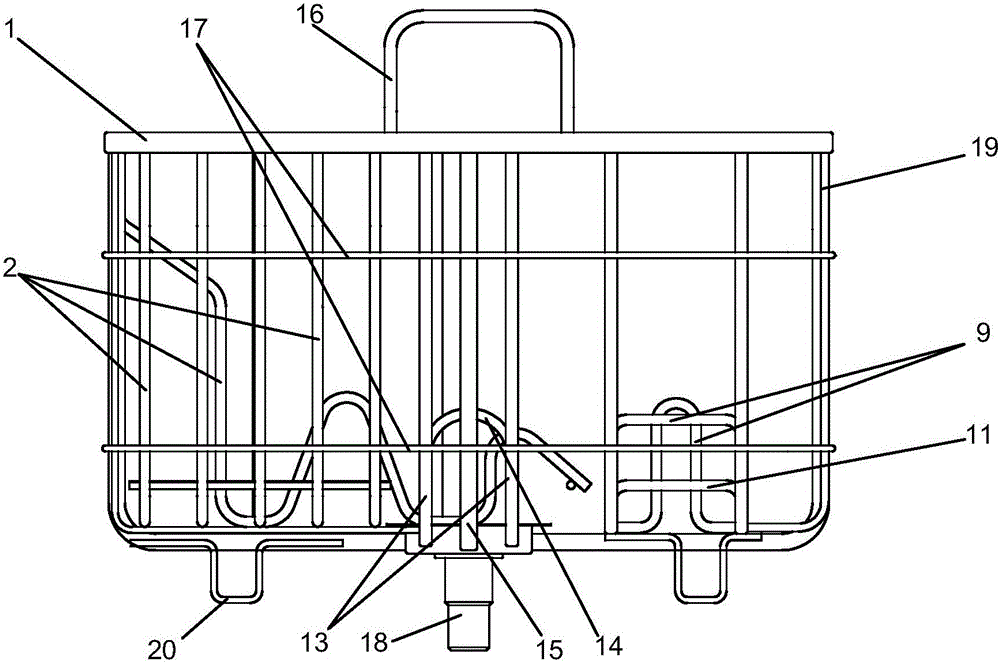

[0042] A main component of a dishwasher, which has a frame body, an upper frame 1 made of pipe sections is connected to the frame body, and the upper frame 1 is composed of a left frame part 1-1, a rear frame part 1-2, a right frame part 1-3 and The front frame part 1-4 is surrounded into a chamfered rectangular shape, and there are a number of through holes 1-5 sealed with the corresponding nozzles under the upper frame 1, and there are handles 16 on the left and right sides of the upper frame. The bottom is provided with a water inlet chamber 5, which is connected with a water inlet interface 18 below the water inlet chamber. Pipe B4, main through pipe C8, main through pipe D10, the upper bend sections of main through pipe A, main through pipe B, main through pipe C and main through pipe D are respectively sealed and connected to the left frame part 1-1 of the upper frame 1 , the rear frame part 1-2, the right frame part 1-3, the through hole 1-5 provided below the front fra...

Embodiment 2

[0048] This example differs from the previous example in that the rack is a rotary spray rack 23, which replaces the corrugated tube rack in the previous example. The rotary spray rack 23 in this example has an asymmetrical U-shaped water-through support pipe 231, the upper end of the short limb of the asymmetric U-shaped water-through support pipe is pivotally connected with a pivoted arm 232 through a pin shaft 233 connected in the horizontal direction. The water spray hole 23212 is provided with a cover plate 2322 behind the substrate, and the long limb of the asymmetrical U-shaped water-through support pipe extends upwards and is sealed to the through hole below the upper frame.

[0049] The pressurized hot water is input from the water inlet port 18, reaches the water inlet chamber 5, enters the upper frame 1 through the main pipe A15, the main pipe B4, the main pipe C8, and the main pipe D10, and then flows through the asymmetrical U-shaped The long limb of the support p...

Embodiment 3

[0051] This example differs from Example 1 in that the rack is a shower spray rack 25, replacing the corrugated tube rack in Example 1. The shower spray rack in this example has an L-shaped water-through support pipe 251 The horizontal section of the L-shaped water-passing support pipe is connected with a basin-shaped spray cover 252, and the front of the basin-shaped spray cover is provided with the spray hole, and the vertical section of the L-shaped water-passing support pipe extends upwards and is connected to the above-mentioned via holes below the box.

[0052] The pressurized hot water is input from the water inlet port 18, reaches the water inlet chamber 5, enters the upper frame 1 through the main through pipe A15, the main through pipe B4, the main through pipe C8, and the main through pipe D10, and then flows through the L-shaped water support pipe The vertical section of 251 enters, reaches basin shape spray cover 252, then sprays from the spray hole of basin shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com