Vacuum clamping device and method

A technology of clamping device and vacuum clamp, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problem of inability to absorb thin-walled frame-type plate parts, etc., and achieve strong adjustability, flexible use, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

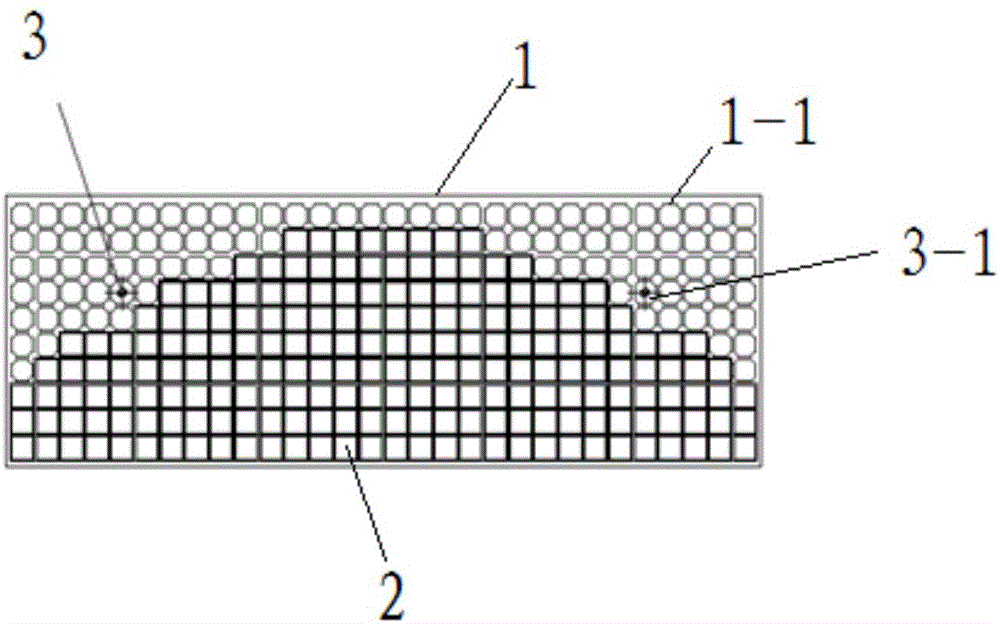

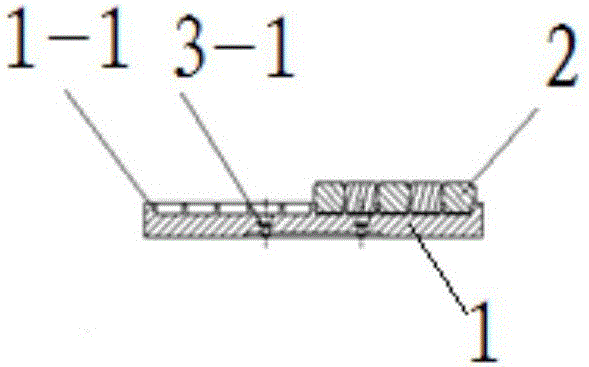

[0017] see Figure 1-2 , a vacuum clamping device provided by an embodiment of the present invention is used for clamping a workpiece; the clamping device includes: an adsorption plate 1, a vacuum adsorption mechanism, several pads 2 and a sealing mechanism.

[0018] The adsorption plate 1 is provided with a plurality of grooves 1-1, and ventilation holes are arranged in the plurality of grooves 1-1.

[0019] The vacuum adsorption mechanism communicates with the ventilation holes opened on the adsorption plate 1 .

[0020] One end of the plurality of spacers 2 is respectively movably arranged in the plurality of grooves 1-1, and the arrangement position of the plurality of spacers 2 on the adsorption plate 1 matches the shape of the workpiece.

[0021] The sealing mechanism is connected to the other ends of the pads 2, and the sealing mechanism forms a closed space on the supporting surface composed of the pads 2, and the shape of the closed space matches the shape of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com