Heat preservation container

A technology for thermal insulation containers and lids, which is applied in the directions of closing, packaging, and sealing parts with auxiliary devices, etc. problem, to achieve the effect of ensuring the water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

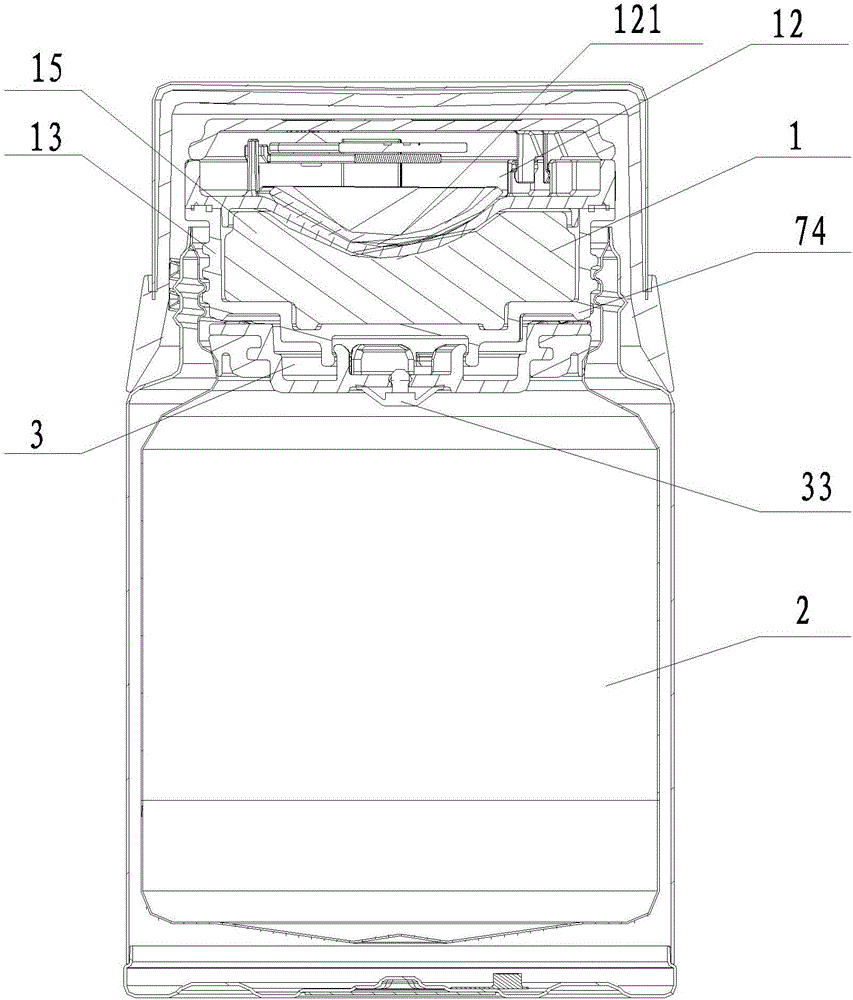

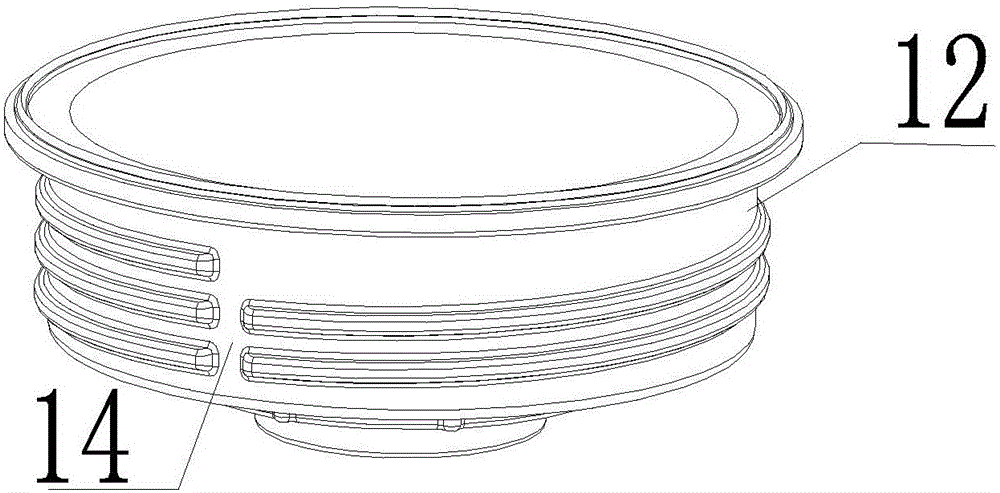

[0037] A kind of heat preservation container, comprising: such as figure 1 , image 3 , Figure 4 As shown, the bottle body 2 with the top opening, the cover body 1 with the screw connection opening, and the exhaust lower cover 3 clamped at the lower end of the cover body 1,

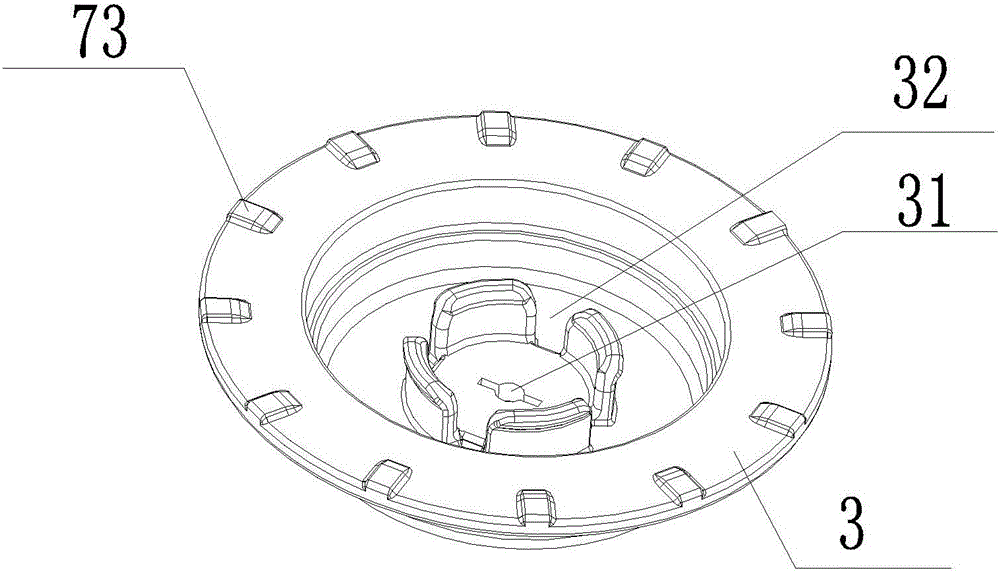

[0038] A ring-shaped female buckle 71 is arranged at the center of the lower end of the cover body 1, and a ring-shaped sub-buckle 72 matching the ring-shaped female buckle 71 is arranged on the side of the exhaust lower cover 3 facing the cover body 1;

[0039] The annular sub-buckle 72 offers some air guide grooves 32 along the axis ring array, and the exhaust lower cover 3 offers the exhaust hole 31 at the axis of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com